0102030405

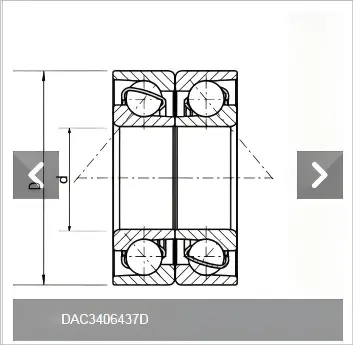

Automobile bearings DAC3406437D

Automobile bearings DAC3406437D

Model: DAC3406437D

Series: Automobile wheel hub bearing unit

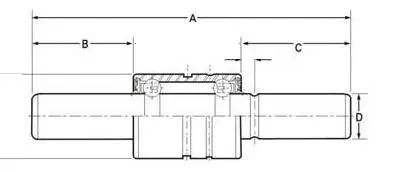

d:34 mm

D:64 mm

B:37 mm

rmin:2.5 mm

Bearings have an important impact on the performance of the entire vehicle. In terms of reliability, once damaged, it will affect the driving of the entire vehicle. In terms of safety, the installation position of some bearings is very important. For example, the wheel hub bearing is to support the weight of the entire vehicle. Once a failure occurs, it will affect the safety of the entire vehicle. In terms of comfort, bearings are not only closely related to the smooth operation of the vehicle, but also those bearings of poor quality are prone to produce loud noise.

For such an important automotive component, relevant industry insiders remind you that you cannot ignore its existence. Here are some tips on the use and maintenance of automotive bearings:

Tip 1: The vehicle should work within the rated load range. Severe overloading will directly lead to bearing overload, which will cause early failure of the bearing. More seriously, it may cause vehicle failure and personal safety accidents.

Tip 2: The bearing should be prohibited from being subjected to some abnormal impact loads.

Tip 3: Check the use status of the bearing regularly, and pay attention to whether there is abnormal noise or local rapid temperature rise in the bearing.

Tip 4: Add lubricating oil or grease regularly and quantitatively as required to ensure the normal operation of the bearing.

Tip 5: According to the use of the vehicle, the lubricating oil should be completely replaced at least every six months, and the bearing should be carefully inspected to prevent accidents.

Tip 6: The inspection method of the shaft under maintenance is: clean the disassembled bearing with kerosene or gasoline, carefully observe whether the inner and outer cylindrical surfaces of the bearing are sliding or creeping, and also check whether the inner and outer raceways of the bearing are peeling or pitting, and whether the rolling elements and cages are worn and deformed, etc. We can judge whether the inspected bearing can continue to be used based on the comprehensive situation of the bearing inspection.