Exploring 2025 Trends in Self Aligning Roller Bearings and How to Optimize Your Sourcing Strategy

As we look ahead to 2025, the self-aligning roller bearings market is expected to witness significant transformations driven by advancements in manufacturing technologies and evolving industry demands.

According to a report by Market Research Future, the global self-aligning roller bearings market is projected to grow at a compound annual growth rate (CAGR) of 5.6% during the forecast period. This growth presents a unique opportunity for sourcing strategies, particularly emphasizing the importance of partnering with a

"Self-Aligning Roller Bearings Factory Direct" for cost-effective and high-quality products.

Additionally, factors such as the rising demand for lightweight and high-performance machinery in sectors like automotive and aerospace further underscore the need for optimized sourcing to align with these industry trends.

In this blog, we will explore the significant trends influencing the market in 2025 and provide insights on how to refine your sourcing strategies to capitalize on these opportunities.

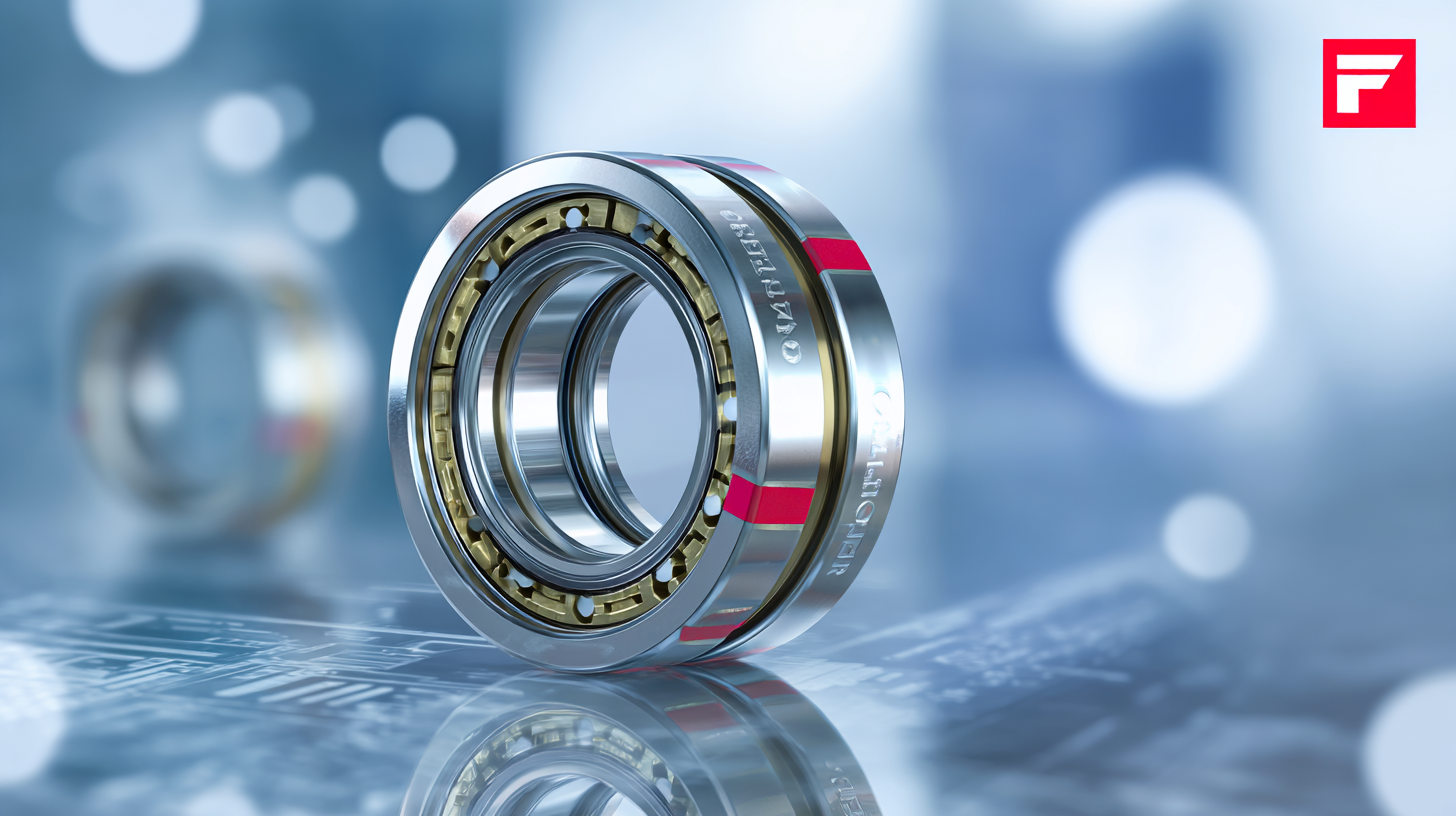

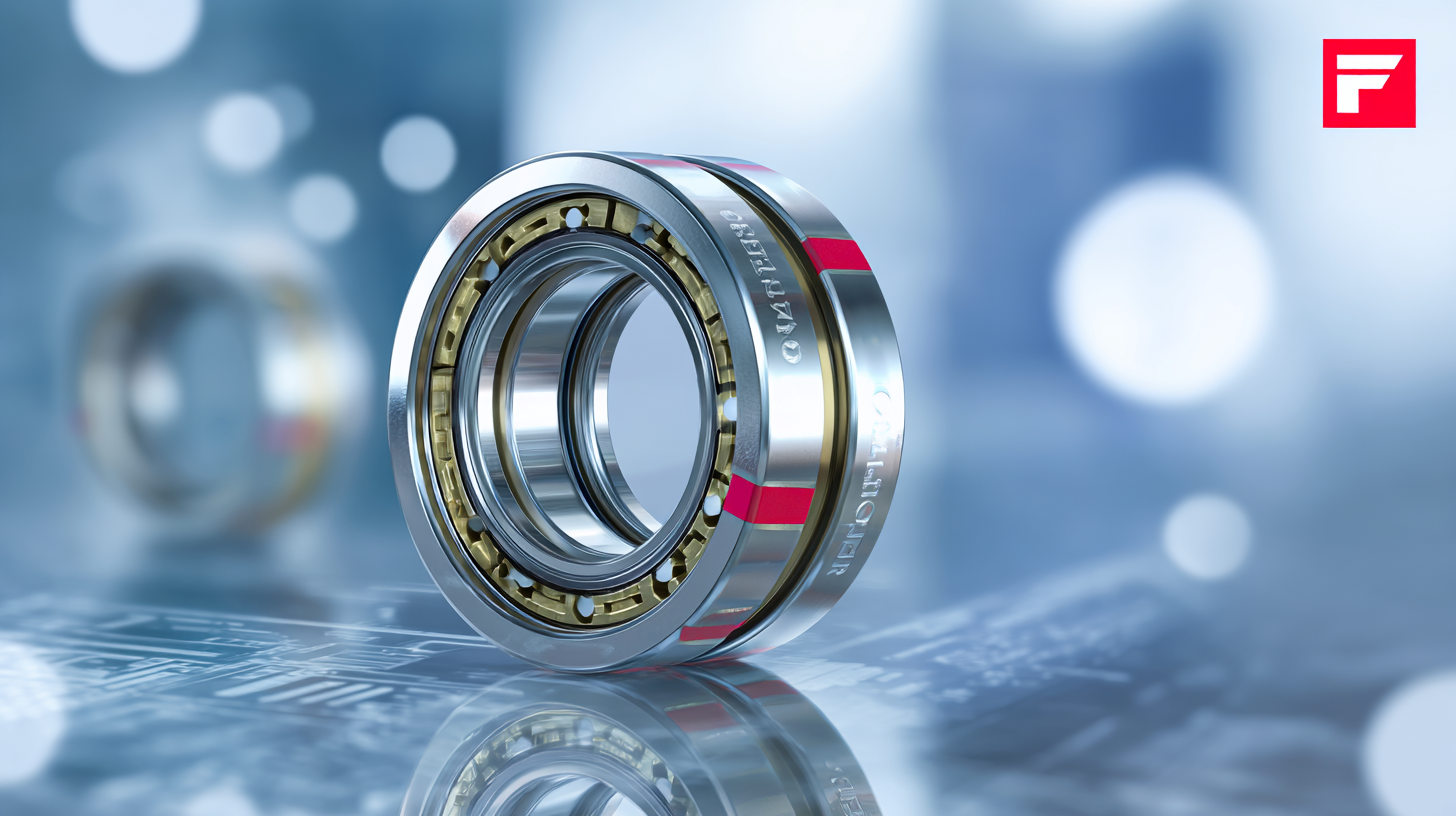

Emerging Alternatives in Self-Aligning Roller Bearing Technologies for 2025

As we look ahead to 2025, the landscape of self-aligning roller bearing technologies is poised for significant transformation. Emerging alternatives focusing on advanced materials and innovative design principles are reshaping the market. For instance, the introduction of polymer-based bearing materials not only reduces weight but also offers enhanced corrosion resistance, presenting a compelling option in environments prone to moisture and chemical exposure. Moreover, these materials have the potential to lower manufacturing costs while maintaining high performance standards.

In addition to materials, advancements in additive manufacturing techniques are revolutionizing the production of self-aligning roller bearings. This technology allows for the creation of complex geometries that traditional machining cannot achieve, enabling better load distribution and improved fatigue resistance. As manufacturers explore these alternatives, they must also consider the integration of smart technologies, such as embedded sensors, which provide real-time monitoring of bearing conditions. This integration enhances operational efficiency, allowing businesses to optimize maintenance schedules and reduce downtime, thus strengthening their overall sourcing strategy.

Evaluating Performance and Cost-Effectiveness of Alternative Options

In the evolving landscape of self-aligning roller bearings, evaluating performance and cost-effectiveness is becoming paramount for manufacturers aiming to optimize their sourcing strategies. A significant trend for 2025 reveals that companies will increasingly seek alternatives that not only meet mechanical specifications but also align with sustainability goals. For instance, a recent report highlighted that incorporating advanced materials could enhance bearing performance by up to 20%, reducing wear and prolonging service life while also decreasing overall operational costs.

Moreover, as digital transformation accelerates, businesses will face pressures to adapt their procurement processes. With cloud migration becoming a priority, the sourcing of components like self-aligning roller bearings must integrate real-time data analytics to assess the viability of alternative options effectively. For example, leveraging predictive maintenance strategies could cut down downtime by as much as 30%, enabling companies to reap substantial savings over their procurement cycles. Embracing these technological advancements and alternatives can lead to a more resilient and cost-effective sourcing framework in the coming years.

Sourcing Strategies: Navigating the Alternative Bearing Market

As the bearing industry evolves, sourcing strategies must adapt to changing market dynamics.

Navigating the alternative bearing market requires a keen understanding of both supplier capabilities

and product performance. When exploring options for self-aligning roller bearings, it's crucial to

focus on quality and reliability. This can

significantly impact the longevity and efficiency of your applications.

Tip 1: Research and vet potential suppliers

thoroughly. Look for companies with proven track records, certifications, and customer testimonials.

Attending industry trade shows can also be a valuable way to meet suppliers in person and assess their offerings.

Additionally, consider diversifying your sourcing strategy

to mitigate potential risks associated with supply chain disruptions. Building relationships with multiple vendors

can ensure you're not overly reliant on a single source, allowing for greater flexibility and agility

in your procurement processes.

Tip 2: Implement a robust evaluation process that

assesses both technical specifications and cost-effectiveness. Use tools like supplier scorecards to compare

different options based on performance metrics that matter to your business objectives. This

data-driven approach will help you make informed

decisions in a competitive alternative bearing market.

Impact of Eco-Friendly Materials on Self-Aligning Roller Bearings in 2025

As we look towards 2025, the use of eco-friendly materials in the production of self-aligning roller bearings is poised to transform the industry. These materials, derived from sustainable sources, not only help reduce the environmental impact of manufacturing processes but also enhance the performance and longevity of bearings. Innovations such as bioplastics and recycled metals are being increasingly integrated into designs, offering a compelling alternative to traditional materials. This shift is not merely a trend; it reflects growing consumer demand for sustainable practices and products.

The adoption of these eco-friendly materials requires manufacturers to rethink their sourcing strategies. Companies must ensure that their supply chains align with sustainability goals, prioritizing suppliers who commit to responsible material sourcing and eco-conscious production methods. By optimizing purchasing strategies to include eco-friendly options, businesses can reduce their carbon footprint while maintaining product quality and performance. This transition to a greener supply chain not only appeals to environmentally conscious consumers but also aligns with global regulatory trends aimed at promoting sustainability across industries.

Exploring 2025 Trends in Self Aligning Roller Bearings and How to Optimize Your Sourcing Strategy

| Trend |

Description |

Eco-Friendly Material |

Impact on Performance |

Sourcing Strategy |

| Increased Demand for Sustainability |

More manufacturers are seeking sustainable solutions to reduce environmental impact. |

Recycled Steel |

Enhances wear resistance and reduces carbon footprint. |

Focus on suppliers that utilize certified eco-friendly materials. |

| Technological Advancements |

Adoption of smart technologies for better maintenance monitoring. |

Biodegradable Lubricants |

Improves sustainability while ensuring optimal performance. |

Invest in technology that enables tracking of material sourcing. |

| Global Supply Chain Challenges |

Ongoing disruptions necessitate agile sourcing strategies. |

Natural Fibers |

Can be used in support structures, reducing weight. |

Diversify supplier base to mitigate risks. |

| Regulatory Compliance |

Increasing laws regarding sustainability and materials used. |

Non-toxic Coatings |

Ensures compliance with safety standards while improving longevity. |

Regularly audit suppliers for compliance with regulations. |

Future Innovations: Predicting Trends in Alternative Bearing Designs

As we look forward to 2025, the bearing industry is poised for transformative innovations, particularly in alternative bearing designs. Research from MarketsandMarkets anticipates that the global bearing market will grow from $80 billion in 2020 to over $100 billion by 2025, driven by advancements in materials and manufacturing processes. Among these innovations, self-lubricating bearings and hybrid designs—combining ceramic and steel—are set to revolutionize applications in harsh environments, where traditional bearings often fail.

Another trend worth noting is the rising demand for environmentally friendly solutions. A report by Grand View Research highlights that the market for eco-friendly bearings is expected to expand at a CAGR of 5.4% from 2021 to 2028. This shift is pushing manufacturers to explore bio-based or recyclable materials that not only enhance performance but also minimize environmental impact. Automated design tools and simulation software are becoming increasingly vital in optimizing these new bearing designs, enabling engineers to chart more efficient sourcing strategies that align with sustainability goals while meeting the performance demands of various industries.

2025 Trends in Self Aligning Roller Bearings

This chart illustrates predicted market trends for self-aligning roller bearings in various industries by 2025, including automotive, aerospace, and industrial machinery, highlighting the growing demand for alternative bearing designs.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us