2026 Best Deep Groove Ball Bearings Wholesale Guide for Buyers

In the realm of mechanical engineering, "Deep Groove Ball Bearings Wholesale" plays a pivotal role. According to the latest data from the Global Bearing Market report, the demand for these bearings is expected to grow significantly, driven by increasing industrial applications. However, amidst this growth, buyers face challenges in sourcing quality products at competitive prices.

Expert John Smith, a renowned figure in the bearings industry, stated, “Understanding quality versus cost is critical in the Deep Groove Ball Bearings Wholesale market.” His insight reflects a common dilemma for wholesalers and manufacturers alike. Customers often find it difficult to balance affordability with performance.

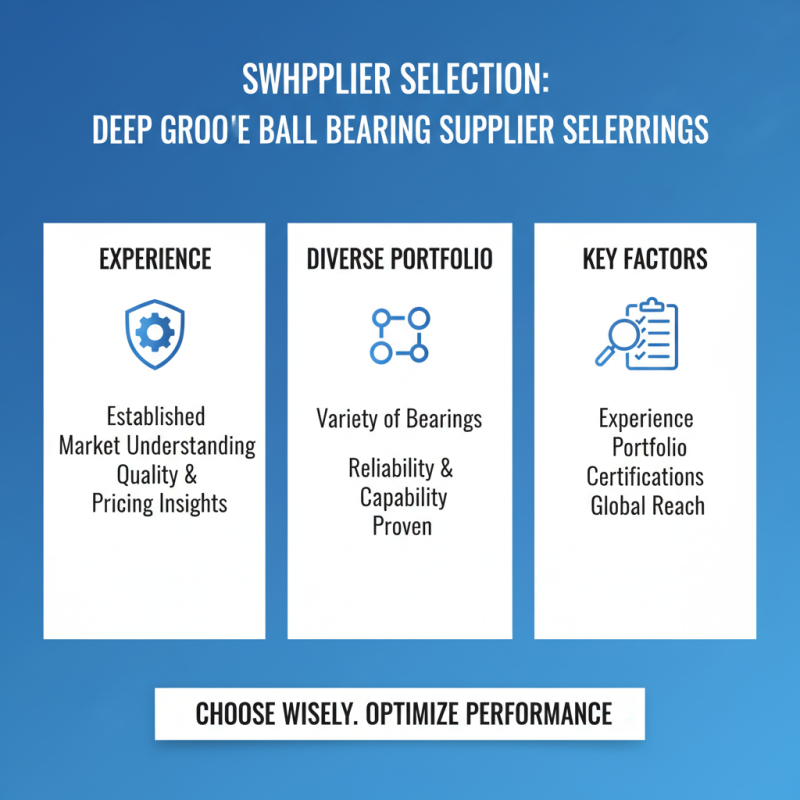

Furthermore, the variety of options available can be overwhelming. Buyers must navigate through numerous manufacturers, each claiming superiority in quality. Reflecting on this environment, it’s crucial to assess suppliers carefully. Quality assurance should not be overlooked, even amid cost-cutting pressures.

Understanding Deep Groove Ball Bearings: Key Features and Benefits

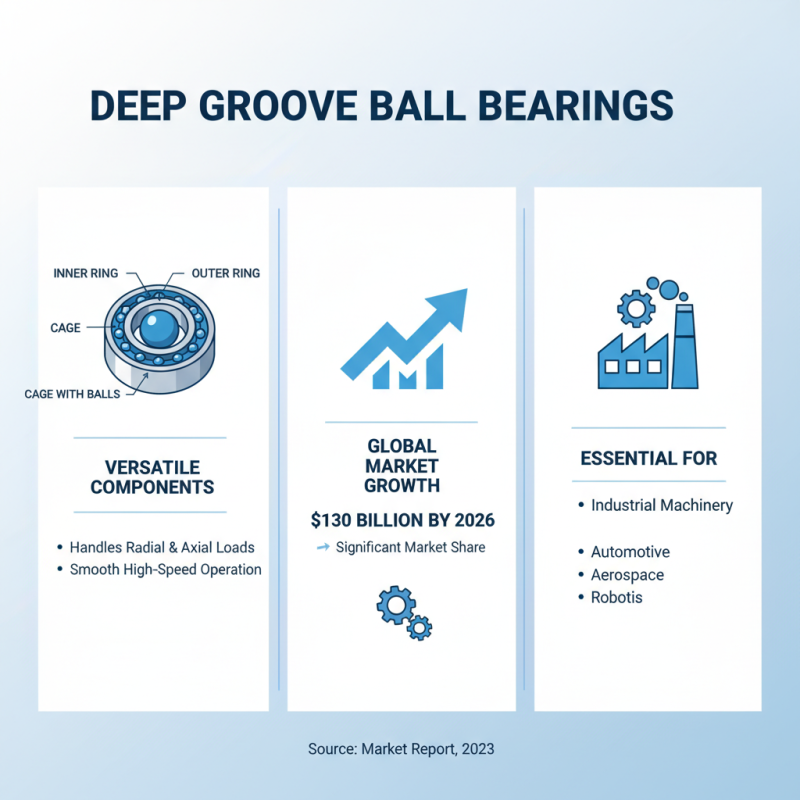

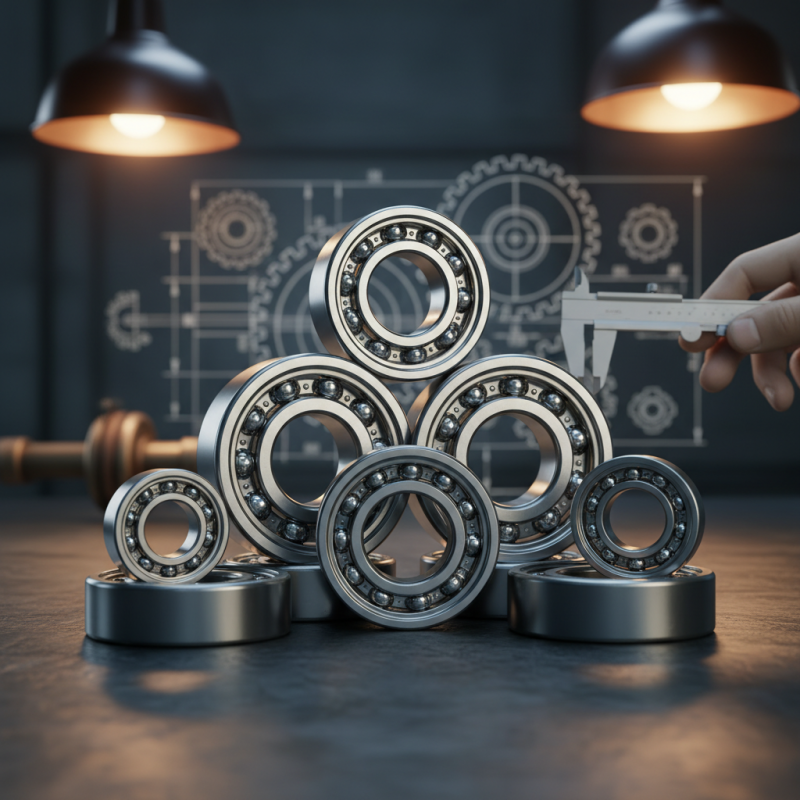

Deep groove ball bearings are essential components in numerous mechanical applications. They are designed to handle both radial and axial loads, making them versatile. The unique geometry allows them to run smoothly at high speeds, which is a crucial feature for industrial machinery. According to a recent market report, the global bearing market is projected to reach $130 billion by 2026, with deep groove ball bearings accounting for a significant share.

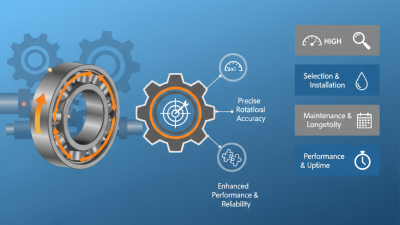

One key advantage of deep groove ball bearings is their low friction coefficient. This characteristic minimizes energy loss, enhancing overall efficiency. However, it’s vital to ensure proper lubrication and installation. A significant 25% of bearing failures stem from improper handling. Many buyers overlook this aspect, leading to costly downtime and maintenance. Understanding the correct parameters is crucial for effective performance.

Additionally, deep groove ball bearings are available in various sizes. This diversity supports various industries ranging from automotive to aerospace. Yet, not all suppliers maintain high-quality standards. Buyers must conduct thorough research and avoid jumping to conclusions based on price alone. Balancing cost and quality is necessary for long-term savings and reliability.

Types of Deep Groove Ball Bearings: A Comprehensive Overview

Deep groove ball bearings are essential components in various machinery. They come in several types, each catering to different applications. The most common types include single-row, double-row, and miniature deep groove ball bearings. Each has unique features that suit specific needs.

Single-row deep groove ball bearings are versatile and widely used. They are great for applications with moderate loads and speeds. Double-row bearings offer higher load capacities and are ideal for heavy-duty applications. Miniature varieties are perfect for compact equipment where space is limited.

Tip: When choosing the right bearing, consider the load and speed requirements. It can make a difference in performance.

It's essential to reflect on your choice. Overlooking details like material and lubrication can lead to failures. Not all bearings fit every application. Take the time to assess your specific needs before purchasing.

Tip: Always consult with experts when uncertain. Getting advice can help avoid costly mistakes.

2026 Best Deep Groove Ball Bearings Wholesale Guide for Buyers

| Bearing Type |

Dimensions (mm) |

Load Rating (N) |

Speed Rating (RPM) |

Material |

| Single Row Deep Groove |

20 x 42 x 12 |

4000 |

12000 |

Chrome Steel |

| Double Row Deep Groove |

30 x 62 x 16 |

5500 |

10000 |

Stainless Steel |

| Single Row Deep Groove with seals |

25 x 52 x 15 |

4800 |

9000 |

Chrome Steel |

| Single Row Deep Groove with shields |

35 x 72 x 17 |

6000 |

8500 |

Stainless Steel |

Quality Standards and Certification for Deep Groove Ball Bearings

When selecting deep groove ball bearings, understanding quality standards is crucial. These bearings are used in various applications, from automotive to industrial machinery. Each type has specific certifications that ensure performance and reliability. It is essential to check these standards before making a purchase. Many buyers focus solely on price, forgetting that quality can vary significantly.

One common standard is ISO 9001, which addresses quality management systems. This certification helps buyers know that manufacturers follow strict protocols. However, not all manufacturers comply fully with these standards. Some may have inconsistencies in their production processes. It's important to ask for documentation and proof of compliance from suppliers.

Another critical aspect is to look for certifications specific to safety and durability. Bearings should withstand various conditions, including temperature changes and load stress. Without proper certifications, there might be hidden risks. Evaluating each supplier's reputation can help, but it's not foolproof. Quality checks and testing are often overlooked, leading to potential failures in performance.

Cost Factors and Pricing Strategies in Bulk Purchases of Bearings

When considering bulk purchases of deep groove ball bearings, cost factors play a crucial role. The price can vary widely based on material, size, and quantity. Buyers often face challenges in predicting expenses, as raw material prices fluctuate frequently. Once you commit to a larger order, prices might seem fixed, but hidden costs can emerge. These include shipping fees, customs duties, and increased handling costs.

Another important aspect is negotiating pricing strategies. Less known suppliers might offer lower introductory prices. However, this might lead to quality inconsistencies. Some buyers opt for established brands, assuming higher prices equal better quality. This isn't always the case. Evaluating suppliers through samples before bulk ordering can be beneficial. Testing smaller quantities can help avoid pitfalls related to poor quality. Don't overlook the potential for savings by assessing a variety of suppliers. Always rethink your initial choice; you may discover a more cost-effective option.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us