2026 How to Choose Heavy Duty Bearings for Mining Machinery

In the robust world of mining, machinery performance heavily relies on the quality of its components. Mining Machinery Heavy-Duty Bearings are crucial for ensuring operational efficiency and longevity. Industry expert John Thompson, renowned for his work with heavy machinery, emphasizes, "The right bearings can make or break a mining operation."

Selecting the appropriate bearings is not a straightforward task. Factors such as load capacity, environmental conditions, and lubrication play significant roles. Manufacturers face challenges in maintaining high standards while balancing cost and performance. Too often, decisions are made based on immediate costs rather than long-term reliability. This can lead to unexpected downtimes and increased maintenance efforts.

Ultimately, understanding the requirements of Mining Machinery Heavy-Duty Bearings can enhance machinery reliability. Attention to detail in selection can prevent breakdowns and prolong service life. However, the industry must continuously adapt to evolving demands and technologies. Continuous reflection on these practices is essential for improvement.

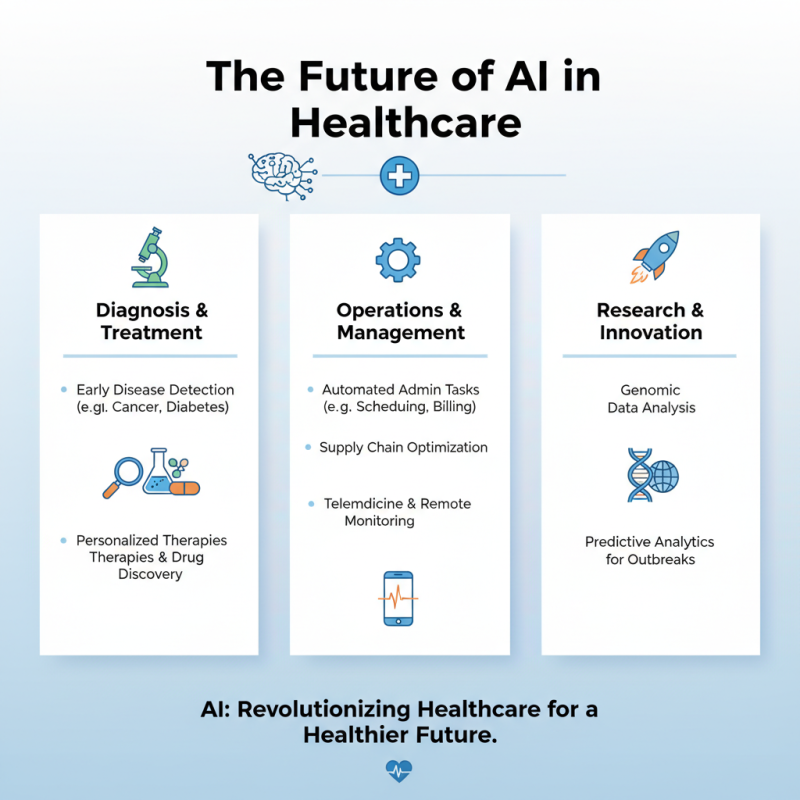

Understanding the Role of Heavy Duty Bearings in Mining Machinery

Heavy duty bearings play a critical role in mining machinery. Their performance directly impacts operational efficiency and equipment lifespan. In harsh mining environments, these bearings face extreme loads, dust, and moisture. According to industry reports, nearly 40% of downtime in mining operations is due to bearing failures. Thus, understanding the selection criteria is vital.

Tip: Assess the specific load and speed conditions for your application. Standard bearings may underperform in extreme conditions. Look for bearings designed to handle axial and radial loads effectively. The material composition is another key factor. High-quality steel can enhance wear resistance and fatigue life.

Moreover, lubrication can affect bearing performance significantly. Incorrect lubrication types can lead to failures. A study indicated that improper lubrication resulted in 50% of the bearing issues in mining machinery. Regular inspection and maintenance should not be overlooked. It is crucial to periodically check for signs of wear or contamination.

Tip: Implement a routine maintenance schedule. This can prevent unexpected failures. Consider using advanced monitoring systems that track bearing performance in real-time. Small changes can lead to significant improvements in productivity. Bear in mind the importance of choosing the right bearing type. It can make a difference in operation and reliability.

Key Factors to Consider When Selecting Heavy Duty Bearings

When selecting heavy-duty bearings for mining machinery, several key factors come into play. Load capacity is critical. Bearings must handle heavy loads typical in mining operations. According to a recent industry report, over 40% of bearing failures in mining result from inadequate load ratings. These failures can lead to significant downtime.

Another vital consideration is the operating environment. Bearings often face extreme conditions, including dust, moisture, and temperature fluctuations. A study showed that bearings exposed to harsh environments can lose 30% of their lifespan without proper sealing. Ensure that the bearings have adequate sealing features to protect against contaminants. The right lubrication also matters. Improper lubrication can lead to overheating and premature failures.

Furthermore, material composition influences durability. High-quality steel or ceramic materials can significantly enhance performance. It is essential to assess the materials based on specific operational requirements. Some users prioritize low-cost options, but this may compromise overall performance and reliability. The balance between cost and quality must be carefully evaluated. Making the wrong choice can lead to costly repairs and increased operational risks.

Maintenance Best Practices for Long-lasting Heavy Duty Bearings

Heavy-duty bearings are critical for mining machinery. Proper maintenance extends their lifespan significantly. Studies indicate that over 30% of equipment failures stem from bearing issues. Thus, implementing effective maintenance practices is vital.

Regular lubrication is essential. It reduces friction and wear, improving efficiency. A study found that inadequate lubrication can decrease bearing life by up to 50%. Monitoring lubricant condition is also crucial. Dirty or degraded oil leads to premature failure.

Vibration analysis serves as an effective diagnostic tool. It detects potential problems before they escalate. Reports show that early detection can cut downtime by 20%. Additionally, routine inspections should not be overlooked. Inconsistent checking can result in overlooking minor issues that escalate into major failures later.

2026 How to Choose Heavy Duty Bearings for Mining Machinery - Maintenance Best Practices for Long-lasting Heavy Duty Bearings

| Bearing Type |

Load Capacity (kN) |

Speed Rating (rpm) |

Material |

Maintenance Interval (months) |

| Spherical Roller Bearing |

150 |

800 |

Steel |

12 |

| Tapered Roller Bearing |

180 |

600 |

Alloy |

10 |

| Cylindrical Roller Bearing |

200 |

900 |

Chrome Steel |

8 |

| Deep Groove Ball Bearing |

130 |

1200 |

Ceramic |

6 |

Common Challenges in Bearing Performance and How to Overcome Them

When it comes to mining machinery, bearing performance is crucial. Heavy-duty bearings face various challenges. High loads, abrasive dust, and extreme temperatures can affect their functionality. Ensuring that your bearings can withstand these challenges is essential for equipment longevity.

Tips: Regular inspections are vital. Look for signs of wear or overheating. It’s important to address minor issues before they become major problems. Not every bearing will perform well in every environment. Test different types to see what works best for your specific conditions.

Another challenge is lubrication. Inconsistent lubrication can lead to bearing failures. Employing the right lubricant can enhance performance and lifespan. Make sure to follow the manufacturer’s guidelines on lubrication frequency and quantity. Over-lubrication can be just as harmful. Keep an eye on how much is being applied.

People often overlook installation errors. Improper alignment can lead to premature bearing failure. Use tools to check alignment before installation. Take your time with this process. A small oversight can cause significant downtime in mining operations. Consider investing time in training personnel on proper installation techniques to enhance reliability.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us