What is Bearing Maintenance & After-Sales Support? Understanding Its Impact on Equipment Longevity

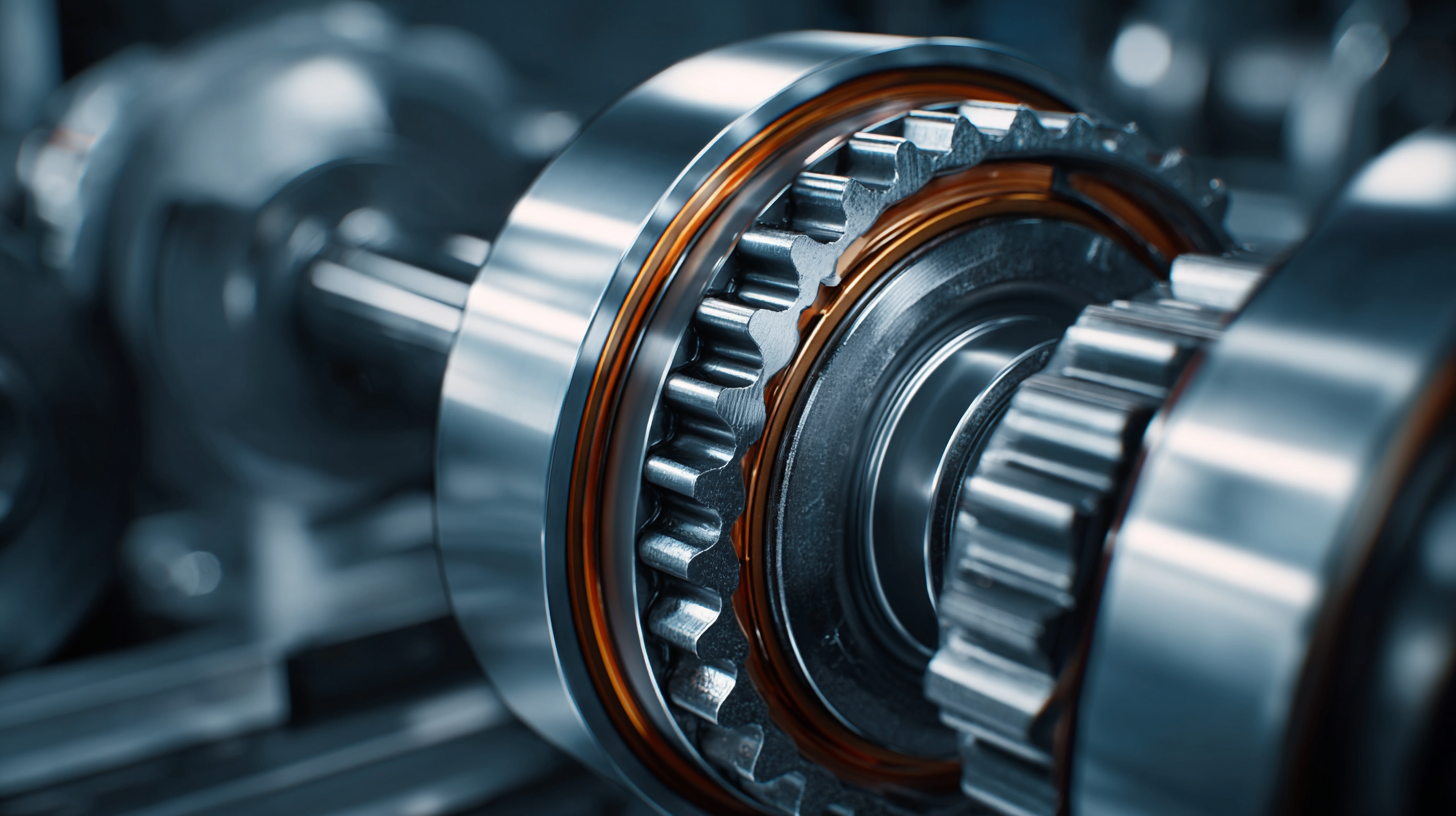

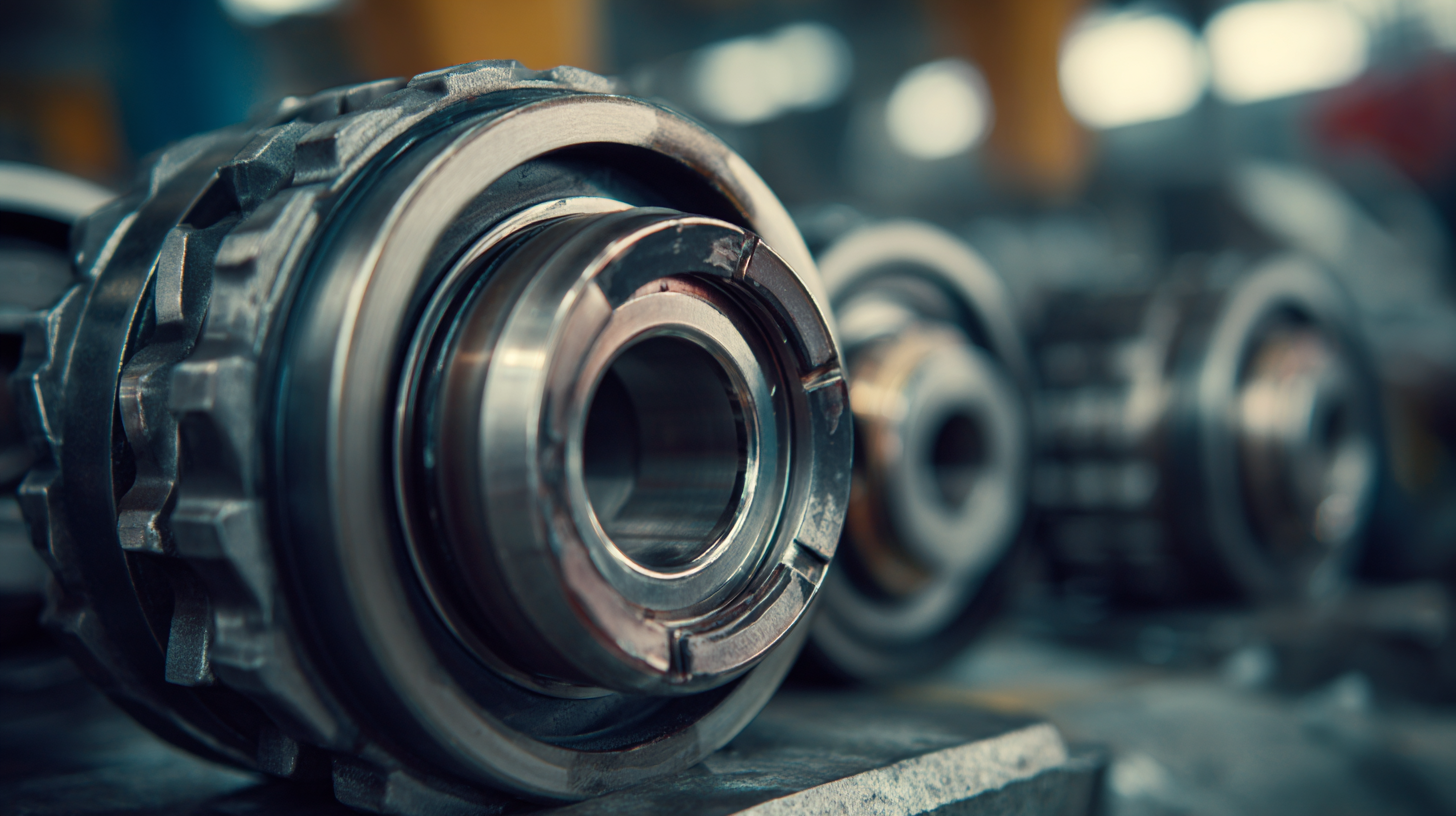

In the world of machinery and equipment, the significance of

Bearing Maintenance & After-Sales Support cannot be overstated.

These critical aspects not only enhance the operational efficiency of machines but also play a pivotal role

in extending their lifespan. Effective bearing maintenance ensures that components function optimally, reducing

friction and wear, while robust after-sales support provides users with the necessary guidance and resources

to address any issues that may arise post-purchase.

Understanding the intertwined relationship

between these two elements can empower companies to make informed decisions, potentially leading to reduced

downtime, lower repair costs, and enhanced productivity. In this blog, we will delve into the essentials of

bearing maintenance and after-sales support, offering valuable tips and strategies that can significantly impact

equipment longevity.

In the world of machinery and equipment, the significance of

Bearing Maintenance & After-Sales Support cannot be overstated.

These critical aspects not only enhance the operational efficiency of machines but also play a pivotal role

in extending their lifespan. Effective bearing maintenance ensures that components function optimally, reducing

friction and wear, while robust after-sales support provides users with the necessary guidance and resources

to address any issues that may arise post-purchase.

Understanding the intertwined relationship

between these two elements can empower companies to make informed decisions, potentially leading to reduced

downtime, lower repair costs, and enhanced productivity. In this blog, we will delve into the essentials of

bearing maintenance and after-sales support, offering valuable tips and strategies that can significantly impact

equipment longevity.

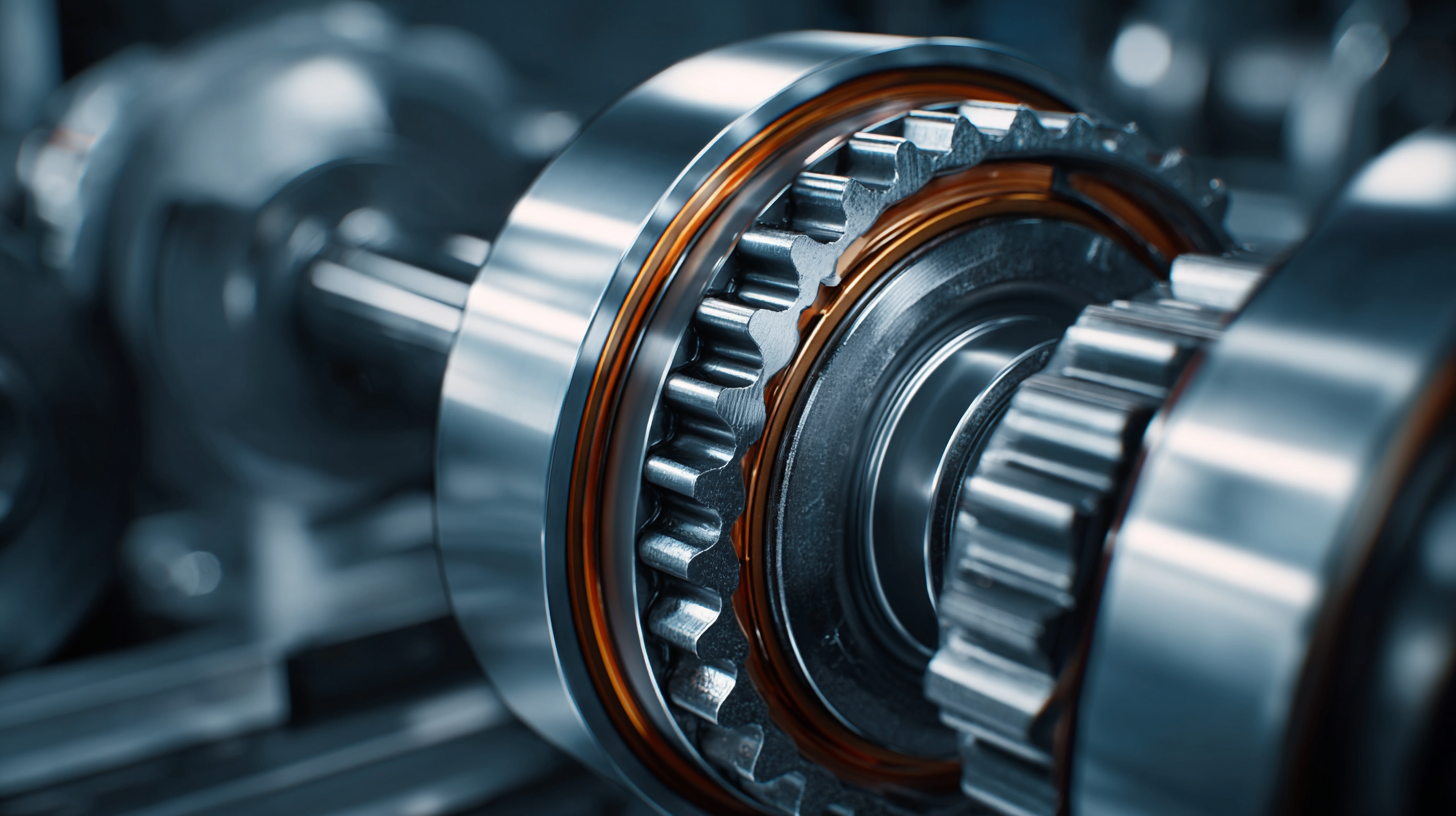

Understanding the Importance of Bearing Maintenance for Operational Efficiency

Bearing maintenance plays a crucial role in enhancing operational efficiency across various industries. Bearings are integral components in machinery, allowing for smooth movement and reducing friction. Regular maintenance helps prevent wear and tear, ensuring that equipment operates at optimal levels. This not only increases the lifespan of bearings but also minimizes downtime, which is vital for maintaining productivity in a business.

Tip: Implement a routine inspection schedule to monitor the condition of bearings. Regular checks can help identify issues before they escalate, allowing for timely interventions and repairs. Additionally, consider using vibration analysis to detect early signs of bearing failure, giving you a heads-up to address potential problems.

Moreover, proper lubrication is key to bearing longevity. Using the correct type of lubricant and applying it at the right intervals can significantly reduce friction and heat buildup. This not only protects the bearings but also enhances the efficiency of the entire machine.

Tip: Keep a detailed lubrication log to ensure bearings are serviced regularly. This practice helps in tracking maintenance schedules and can serve as a reference for future upkeep, thereby optimizing your operational efficiency.

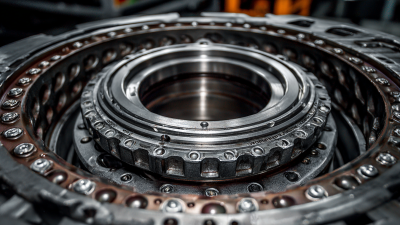

Key Metrics: How Proper Maintenance Increases Equipment Lifespan by Up to 30%

Proper maintenance of bearings is essential for maximizing equipment lifespan, with effective strategies potentially increasing longevity by up to 30%. Regular inspections, lubrication, and timely replacements play a crucial role in preventing premature wear and failure. Ignoring these practices can lead to significant operational disruptions and costs. Implementing a proactive maintenance schedule not only minimizes downtime but also enhances overall equipment performance.

Key metrics that indicate successful bearing maintenance include operating temperature, vibration levels, and lubrication condition. Monitoring these parameters allows for early detection of issues, enabling swift interventions before they escalate into costly repairs. Investing in training for maintenance personnel can further enhance the effectiveness of these practices, ensuring that equipment is maintained to the highest standards. By prioritizing bearing maintenance and after-sales support, businesses can realize substantial cost savings, extend the operational life of their equipment, and improve overall productivity.

What is Bearing Maintenance & After-Sales Support? Understanding Its Impact on Equipment Longevity

| Maintenance Type |

Frequency (per year) |

Impact on Lifespan (%) |

Cost Savings ($) |

Downtime Reduction (%) |

| Preventive Maintenance |

4 |

30 |

1500 |

25 |

| Predictive Maintenance |

6 |

25 |

2000 |

30 |

| Corrective Maintenance |

2 |

10 |

500 |

15 |

| After-Sales Support |

As needed |

20 |

1000 |

20 |

The Role of After-Sales Support in Reducing Downtime for Industrial Equipment

After-sales support plays a crucial role in maintaining the performance and longevity of industrial equipment. When machinery experiences wear and tear, timely assistance from manufacturers can significantly reduce downtime. Efficient after-sales services, including regular maintenance checks and quick access to replacement parts, enable operations to run smoothly. This ensures that potential issues are addressed before they escalate into significant breakdowns, allowing businesses to maintain productivity levels while simultaneously minimizing costly interruptions.

In a competitive industrial landscape, the importance of having robust after-sales support cannot be overstated. It directly impacts a company's profitability and operational efficiency. By fostering a relationship with reliable service providers, businesses can access expert advice and technical support tailored to their needs. This proactive approach to equipment management helps in avoiding unexpected failures and extends the overall lifespan of machinery, ultimately leading to a more resilient and efficient production process.

Best Practices in Bearing Maintenance: Strategies for Maximizing Performance

Bearing maintenance is critical in enhancing equipment longevity, and adopting best practices in this area can significantly boost performance. A proactive approach to maintenance, including regular condition monitoring, is paramount. According to a 2006 study by The Manufacturing Research Center, only 38% of surveyed manufacturers in the US were utilizing Total Productive Maintenance (TPM), underscoring a huge opportunity for improvement. By implementing strategies that shift from reactive to proactive maintenance, organizations can avoid costly downtime and ensure their machinery operates optimally.

Additionally, advanced diagnostics technologies have emerged as game-changers in maintenance practices. Industries are increasingly leveraging predictive maintenance techniques to assess the health of equipment continuously. This trend aligns with the findings from various case studies highlighting that proactive maintenance increases operational efficiency and equipment reliability. In fact, transitioning from outdated maintenance strategies to modern predictive approaches can substantially enhance asset availability and extend the lifespan of critical components like bearings, thus maximizing their performance in various industrial applications.

The Financial Impact of Bearing Failures: Data-Driven Insights for Cost Savings

Bearing failures can lead to significant financial repercussions for businesses, often manifesting in unexpected downtime and costly repairs. According to industry data, a single bearing failure can result in thousands of dollars lost in production time, not to mention the expense involved in replacing damaged equipment. By understanding the root causes of these failures—such as inadequate maintenance, misalignment, or excessive loads—companies can implement proactive measures to mitigate these risks and enhance equipment longevity.

Data-driven insights reveal that an effective bearing maintenance program can significantly contribute to cost savings. For instance, regular monitoring and predictive maintenance can identify potential issues before they escalate into catastrophic failures. This not only reduces the frequency of repairs but also extends the life cycle of bearings, resulting in less frequent replacements. By investing in maintenance and after-sales support, businesses can optimize their operational efficiency and reduce the total cost of ownership, ensuring that their equipment performs reliably over the long term.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us

In the world of machinery and equipment, the significance of

Bearing Maintenance & After-Sales Support cannot be overstated.

These critical aspects not only enhance the operational efficiency of machines but also play a pivotal role

in extending their lifespan. Effective bearing maintenance ensures that components function optimally, reducing

friction and wear, while robust after-sales support provides users with the necessary guidance and resources

to address any issues that may arise post-purchase.

In the world of machinery and equipment, the significance of

Bearing Maintenance & After-Sales Support cannot be overstated.

These critical aspects not only enhance the operational efficiency of machines but also play a pivotal role

in extending their lifespan. Effective bearing maintenance ensures that components function optimally, reducing

friction and wear, while robust after-sales support provides users with the necessary guidance and resources

to address any issues that may arise post-purchase.