Exploring the Benefits of Custom Thrust Ball Bearings in Modern Machinery

In the realm of modern machinery, the importance of precise and efficient components cannot be overstated, with Thrust Ball Bearings Custom Manufacturing emerging as a vital contributor to enhanced performance and reliability. According to a recent report by ResearchAndMarkets, the global bearing market is projected to reach USD 83.6 billion by 2025, driven by the rising demand for advanced machinery across various sectors such as automotive, aerospace, and industrial equipment. Custom thrust ball bearings, designed to accommodate specific load conditions and operational environments, play a crucial role in this growth. They offer benefits such as reduced friction, improved energy efficiency, and the capability to withstand significant axial loads, making them essential for machinery that relies on precision engineering. As industries continue to evolve, the adoption of custom-made bearing solutions will prove pivotal in achieving operational excellence and longevity of machinery.

Benefits of Custom Thrust Ball Bearings in Optimizing Machinery Performance

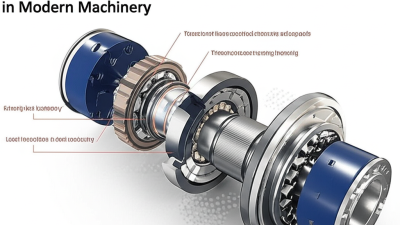

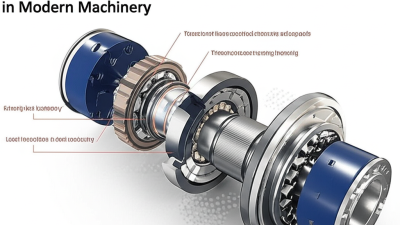

Custom thrust ball bearings play a crucial role in optimizing machinery performance by providing tailored solutions that meet specific operational requirements. These bearings are designed to handle axial loads efficiently, ensuring that machinery operates smoothly and with minimal friction. By customizing the dimensions and material choices of thrust ball bearings, manufacturers can enhance load capacity, improve durability, and reduce maintenance needs, which ultimately leads to increased productivity.

When selecting custom thrust ball bearings, it's essential to consider the operational environment and the specific requirements of your machinery. Factors like load conditions, temperature fluctuations, and contamination levels can all influence bearing performance.

Tips: Always consult with a bearing specialist to determine the best materials and configurations for your application. Additionally, regular maintenance checks on the bearings can prevent unexpected machinery failures and prolong the lifespan of your equipment. Choosing the right seal can also protect the bearings from contaminants while ensuring optimal lubrication.

Enhancing Load Capacity with Advanced Custom Thrust Ball Bearings Design

The design of thrust ball bearings has evolved significantly, allowing for the enhancement of load capacity in modern machinery. Custom thrust ball bearings, tailored to specific applications, can optimize performance by accommodating higher axial loads and improving overall efficiency. These advanced designs utilize specialized materials and geometries, which not only increase durability but also reduce friction and wear over time. By carefully selecting materials and crafting precise dimensions, manufacturers can create bearings that meet the rigorous demands of contemporary mechanical systems.

Moreover, the ability to customize thrust ball bearings enables engineers to address unique challenges posed by different operating environments. For instance, bearings designed for harsh conditions can be treated with coatings that provide additional protection against corrosion and fatigue. This ensures that machinery can operate smoothly under varying loads and speeds, ultimately extending the lifespan of the components. As industries seek to improve reliability and productivity, investing in advanced custom thrust ball bearings becomes a strategic move, optimizing both performance and maintenance.

Reducing Operating Costs through Improved Efficiency of Thrust Ball Bearings

The modern machinery landscape is increasingly benefiting from the use of custom thrust ball bearings, particularly in terms of reducing operating costs through enhanced efficiency. Thrust ball bearings play a vital role in applications where axial loads are present, and their design can be tailored to meet specific operational demands. By optimizing these components for particular machines, manufacturers can minimize friction and wear, leading to smoother operation and prolonged lifespan of the machinery.

Moreover, advancements in material science have enabled the development of high-performance thrust ball bearings that offer improved durability and reliability. These innovations not only contribute to the efficiency of machinery but also lower maintenance requirements and associated costs. As industries seek to boost operational efficiency amid a competitive marketplace, the adoption of custom thrust ball bearings is likely to become a key strategy, ultimately driving growth in the bearings market and ensuring that machinery operates at peak performance for extended periods.

Extending Equipment Lifespan with Tailored Thrust Ball Bearings Solutions

In modern machinery, the integration of custom thrust ball bearings plays a pivotal role in extending equipment lifespan and enhancing operational efficiency. According to a report by the International Society of Automation, equipment failure due to suboptimal bearing performance accounts for up to 30% of industrial downtime. Tailored thrust ball bearing solutions are designed to meet the specific load, speed, and environmental conditions of various applications, significantly reducing the risk of early failures and maintenance costs.

Custom thrust ball bearings exhibit superior durability and performance compared to standard models. Data from a recent study by the Bearing Research Institute indicates that machines equipped with these custom solutions experience a lifespan increase of approximately 25-40%, depending on the operational conditions. By utilizing advanced materials and precise manufacturing techniques, custom bearings offer improved resistance to wear, thermal fluctuations, and contaminants, making them an ideal choice for demanding environments such as manufacturing, mining, and aerospace. With the right tailored solutions, industries can not only enhance the longevity of their machinery but also increase productivity and reduce overall operational expenditures.

Innovative Materials in Custom Thrust Ball Bearings and Their Industry Impact

The advancement of innovative materials in custom thrust ball bearings significantly enhances their performance and durability. Traditional materials such as steel have been complemented and, in some cases, replaced by advanced composites and ceramics. These materials offer superior resistance to wear, corrosion, and extreme temperatures, which is crucial for modern machinery operating in demanding conditions. For instance, ceramic thrust ball bearings provide reduced friction and weight, leading to improved energy efficiency and lower operational costs in various applications.

Moreover, the incorporation of these new materials fosters greater design flexibility, allowing engineers to tailor thrust ball bearings to specific requirements of different industries. The use of lightweight alloys and polymer-based composites can result in bearings that not only meet stringent performance standards but also contribute to the overall reduction in machinery size and weight. This adaptability has profound implications for sectors such as aerospace, automotive, and manufacturing, where efficiency and reliability are paramount. The industry impact of these developments is substantial, driving the evolution of machinery toward more efficient and sustainable practices.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us