The Benefits of Low Noise Electric Motor Bearings Explained?

Low-Noise Electric Motor Bearings are becoming increasingly popular in various industries. These bearings provide substantial advantages, especially in environments where noise reduction is critical. In many applications, noisy motors can disrupt operations and reduce overall productivity. Low-Noise Electric Motor Bearings address this issue effectively.

These specialized bearings minimize vibration and acoustic emissions during motor operation. This leads to a quieter working environment, enhancing comfort for personnel and reducing disturbances. However, understanding the right type and application of these bearings can be challenging. Miscommunication often occurs when selecting the right product for specific needs.

In some cases, users overlook the importance of quality and compatibility. Choosing inferior alternatives can result in poor performance and increased maintenance costs. Therefore, it is essential to weigh the benefits and potential drawbacks of Low-Noise Electric Motor Bearings carefully. Investing in quality bearings ultimately pays off in efficiency and noise reduction.

Understanding Low Noise Electric Motor Bearings

Low noise electric motor bearings are designed to minimize sound during operation. This feature is crucial in various applications, including household appliances and precision instruments. Reducing noise improves user experience and allows machines to function in quieter environments.

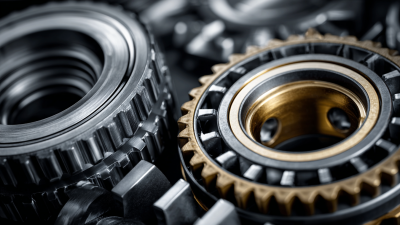

These bearings achieve low noise levels through specific design elements. For instance, they often employ advanced materials and unique geometries. Such innovations help dampen vibrations and reduce friction. However, not all low noise designs are perfect. Some may wear out faster under heavy loads, requiring frequent replacements. This aspect needs careful consideration when making choices.

Moreover, low noise electric motor bearings can enhance energy efficiency. When operating quietly, they often produce less heat. This can lead to longer equipment lifespan and reduced maintenance costs. Yet, one must be cautious. Selecting the wrong bearing for a specific application can lead to suboptimal performance. Understanding the details of each type is essential for getting the best results.

The Benefits of Low Noise Electric Motor Bearings Explained

| Feature |

Description |

Benefits |

| Material Composition |

High-quality steel or ceramic |

Enhanced durability and reduced wear |

| Grease Type |

Low noise, high-performance grease |

Minimizes friction and enhances performance |

| Design Precision |

Tight tolerance manufacturing |

Reduced vibration and noise during operation |

| Seal Design |

Effective sealing technology |

Prevents contamination and extends life |

| Testing Standards |

Rigorous sound and performance testing |

Ensures consistent low noise levels |

Key Features of Low Noise Electric Motor Bearings

Low noise electric motor bearings are designed with specific features to minimize sound. One key feature is their precision manufacturing. Higher precision reduces vibration, leading to quieter operation. Additionally, low noise materials are commonly used. These materials absorb sound, making the motor run more smoothly.

Another aspect is lubrication. Advanced lubrication methods help reduce friction. Less friction means less noise. Some designs include seals that keep contaminants away. This enhances performance and prolongs the bearing's life. Maintenance is less frequent with these bearings, which is a plus.

While low noise electric motor bearings offer significant benefits, they are not without challenges. The initial cost can be higher than standard options. Some users may overlook this after seeing long-term benefits. It's essential to weigh costs against potential savings in maintenance and energy efficiency. Understanding the balance between cost and performance is a step worth taking.

Advantages of Using Low Noise Electric Motor Bearings

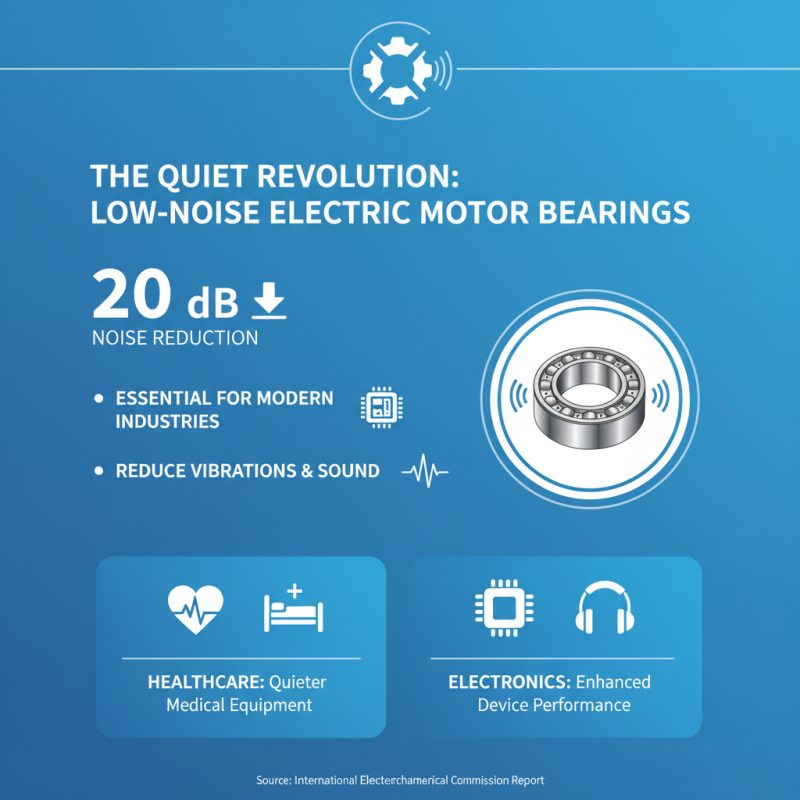

Low noise electric motor bearings are becoming essential in modern industries. These bearings reduce vibrations and noise, creating quieter operations. According to a report by the International Electromechanical Commission, low noise bearings can cut noise levels by up to 20 dB. This reduction is critical for applications in healthcare and electronics, where sound can hinder performance.

An important advantage of using low noise electric motor bearings is improved reliability. They minimize wear and tear, extending the lifespan of the motor. Regular bearings often lead to premature failures. In contrast, low noise options enhance efficiency and lower maintenance costs. They contribute to a smoother operation, which is vital for high-precision equipment.

Tips: Consider your motor’s specific requirements when selecting bearings. Look for the right material and design for optimal performance. Regularly monitor bearing conditions to identify any issues early. This proactive approach can help prevent larger problems down the line. In some cases, achieving low noise can require more careful planning and possibly a budget adjustment.

Applications of Low Noise Electric Motor Bearings in Industry

Low noise electric motor bearings are increasingly sought after in various industries. These components significantly reduce operational noise, improving workplace comfort and regulatory compliance. For example, in the HVAC sector, low noise bearings can lower sound levels to below 40 dB. This is crucial for environments like hospitals where silence is essential.

In the automotive industry, low noise bearings contribute to quieter electric vehicles. A report indicated that reducing noise levels by just 5 dB can enhance passenger experience. Furthermore, in robotics, precision and low noise are vital. Motors equipped with these bearings operate more smoothly, which is essential for tasks demanding high accuracy.

Tips: When selecting bearings, consider both noise levels and performance ratings. Look for products that ensure minimum vibration. Regular maintenance can also prolong bearing life and reduce noise over time. However, some low noise solutions may sacrifice load capacity or efficiency; careful evaluation is necessary.

Maintenance Tips for Low Noise Electric Motor Bearings

Low noise electric motor bearings play a crucial role in enhancing the performance of motors. Regular maintenance is essential to ensure their longevity and efficiency. One important practice is to check for any signs of wear or damage. A simple visual inspection can reveal cracks or corrosion, which can lead to increased noise levels. This process, often overlooked, can save significant costs down the line.

Lubrication is another key aspect. Selecting the right lubricant reduces friction and noise. However, it is vital to avoid over-lubrication. Too much grease can cause the bearings to overheat. You might think you are helping, but this mistake can lead to serious issues. Cleaning the bearings regularly is equally important. Dust and debris can accumulate and create noise. A clean environment is crucial for optimal operation.

Adjusting bearing alignment is often dismissed but can significantly reduce noise. Misalignment leads to uneven wear. Before making any adjustments, check the manufacturer's guidelines. It’s easy to get this wrong if you rush. Noticing these details takes patience and awareness. Be diligent and proactive, and your low noise motor bearings will thank you.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us