Top 5 Benefits of Non Standard Bearings Custom Machining for Your Business

In today's competitive manufacturing landscape, the demand for customized solutions is on the rise, particularly in the bearing industry. A recent report by the International Bearing Association highlights that the global bearings market was valued at approximately $80 billion in 2022, with a projected compound annual growth rate (CAGR) of 8% through 2028. As industries strive for enhanced efficiency and performance, the need for tailor-made components, such as Non-Standard Bearings Custom Machining, has become pivotal.

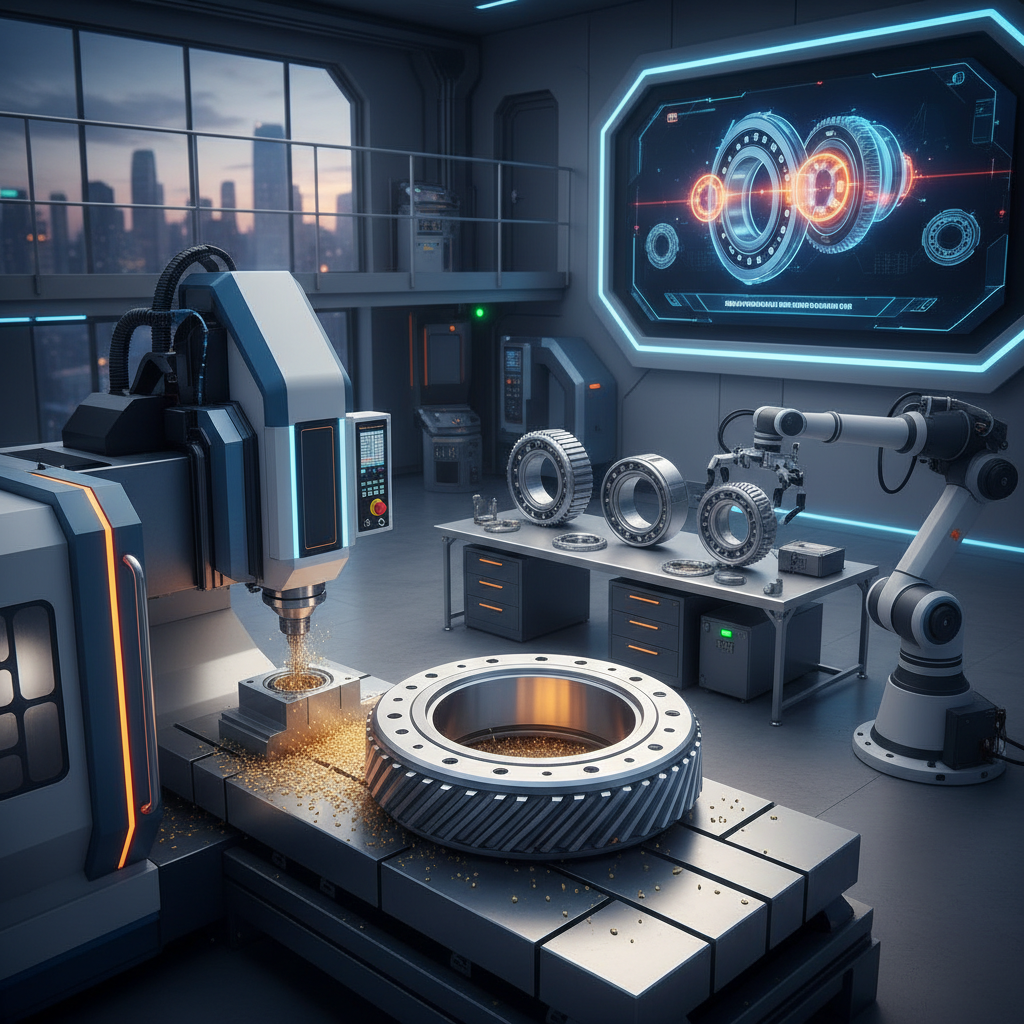

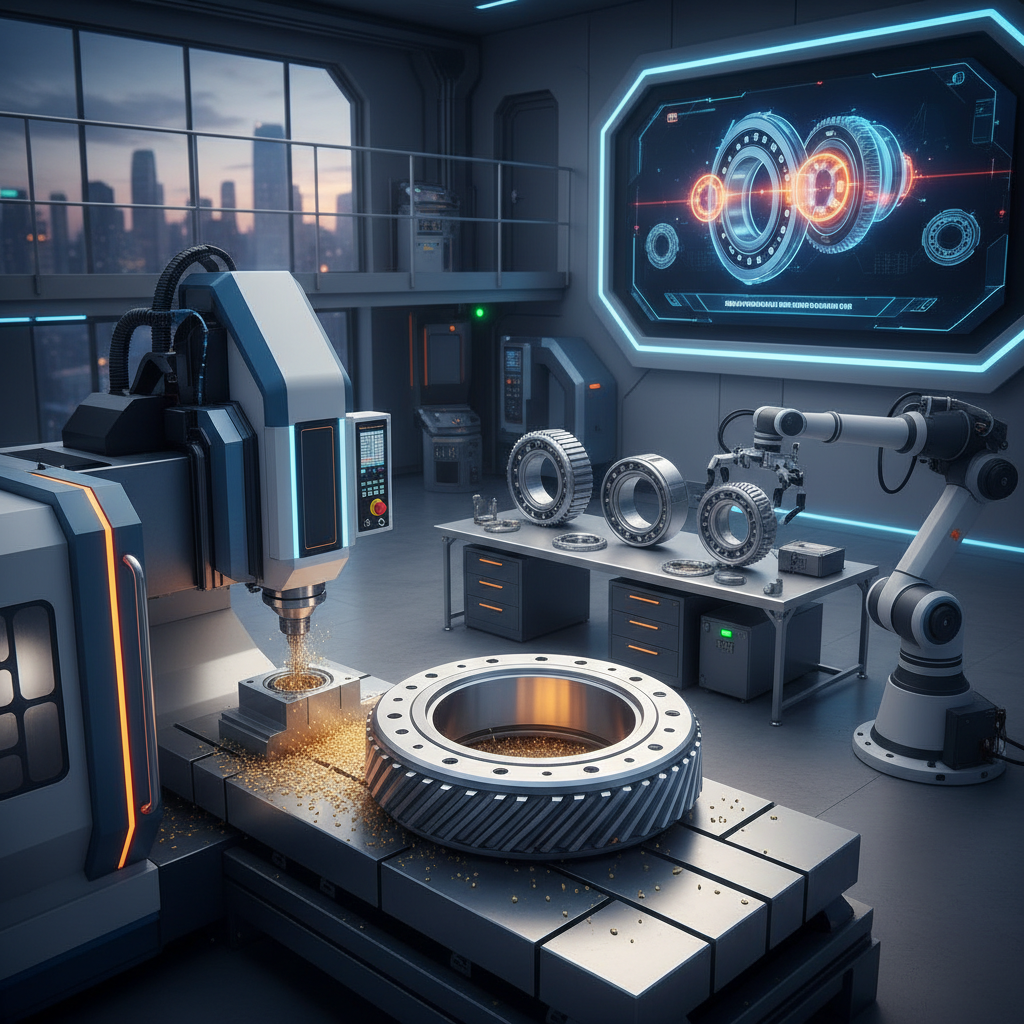

Non-Standard Bearings Custom Machining offers businesses the flexibility to design bearings that meet specific operational requirements. According to a study by MarketsandMarkets, custom machined bearings are expected to substantially contribute to the growth of the advanced machinery sector, addressing the unique challenges faced by various applications in automation, aerospace, and automotive industries. By adopting bespoke machining processes, companies can not only improve their product reliability but also reduce downtime and maintenance costs, thereby boosting overall productivity.

As we explore the top five benefits of Non-Standard Bearings Custom Machining, it becomes evident that investing in customized solutions is no longer merely an option but a strategic imperative for businesses seeking to maintain a competitive edge in an ever-evolving market.

Advantages of Non-Standard Bearings Custom Machining in Manufacturing Efficiency

In today's competitive manufacturing landscape, the efficiency of operations significantly impacts a company's bottom line. One prominent way to enhance this efficiency is through the use of non-standard bearings custom machining. According to a report by MarketsandMarkets, the global market for custom machining services is projected to reach $120 billion by 2025, growing at a CAGR of 5.8%. This unprecedented growth underscores the increasing recognition by manufacturers of the importance of tailored solutions in enhancing productivity.

Non-standard bearings, specifically engineered to meet unique application requirements, offer several advantages. They can drastically reduce friction and wear, as reported by the American Society of Mechanical Engineers (ASME), which estimates that optimized bearing solutions can improve machine lifespan by up to 30%. Furthermore, custom machining allows for precise fitting in machinery, resulting in fewer breakdowns and maintenance schedules. This precision not only minimizes downtime but also supports lean manufacturing principles by streamlining production processes and reducing waste, leading to higher overall efficiency and cost savings for businesses in the long run.

Impact of Custom Machining on Reducing Equipment Downtime and Maintenance Costs

Custom machining of non-standard bearings provides significant advantages for businesses, particularly in minimizing equipment downtime and lowering maintenance costs. According to a market research study, the demand for customized components is on the rise, reflecting a growing recognition of their role in enhancing operational efficiency. By investing in tailor-made solutions, companies can achieve exact specifications that improve their machinery's performance and reliability, thereby reducing unexpected breakdowns that often lead to expensive repair processes.

The impact of custom machining cannot be overstated. With tailored bearings designed specifically for the unique requirements of a machine, businesses can expect an increase in longevity and a decrease in maintenance frequency. The global CNC metal market is expected to experience substantial growth, which aligns with the rising trend of custom solutions in manufacturing. As equipment becomes more efficient, the associated costs of downtime diminish, allowing companies to allocate resources more effectively and improve overall productivity. Furthermore, integrating advanced technologies, such as those powered by artificial intelligence, into manufacturing processes has already begun transforming sectors like corrugated packaging, emphasizing the need for precision and customization in today’s fast-evolving market landscape.

Enhancing Product Performance: How Custom Bearings Improve Operational Reliability

Non-standard bearings custom machining can significantly enhance product performance, leading to improved operational reliability in a variety of industries. These specially designed components enable businesses to tailor their solutions to unique operational requirements, ensuring optimal functionality in challenging environments. By investing in custom bearings, companies can mitigate the risks associated with equipment failure and downtime, ultimately resulting in a more efficient and cost-effective operation.

Tips for selecting the right custom bearing include closely examining your application's specific needs, such as load capacity, speed, and environmental conditions. Work closely with manufacturers to ensure that the materials and designs align with performance objectives. Additionally, thorough testing and validation of prototypes can help identify potential issues before full-scale production begins, ensuring a smoother transition to implementation.

Custom bearings not only improve the longevity of equipment but also enhance overall performance. By utilizing these precision-engineered components, businesses can achieve higher efficiency levels and reduce maintenance costs. When operations run smoothly, it allows for greater focus on core business activities, ultimately driving growth and profitability.

Top 5 Benefits of Non Standard Bearings Custom Machining for Your Business

| Benefit |

Description |

Impact on Performance |

| Enhanced Durability |

Custom machining allows for materials and designs that can withstand higher loads and extreme conditions. |

Reduces maintenance costs and extends product lifespan. |

| Precision Fit |

Custom bearings are designed to fit specific dimensions and requirements of the machinery. |

Improves operational efficiency and reduces energy consumption. |

| Increased Reliability |

Tailored solutions ensure that the bearings function optimally under specific operating conditions. |

Minimizes downtime and operational failures. |

| Cost Efficiency |

While upfront costs may be higher, the long-term savings from performance and durability boost overall ROI. |

Enhances profitability through lower total costs of ownership. |

| Versatility |

Custom machining can accommodate unique applications and specifications across various industries. |

Facilitates innovation and adaptation in product development. |

Cost-Effectiveness of Tailored Solutions in Reducing Waste and Resource Utilization

Custom machining of non-standard bearings offers significant cost-effectiveness, particularly when it comes to reducing waste and optimizing resource utilization. By tailoring solutions to specific operational needs, businesses can avoid the pitfalls associated with generic components that often result in excess manufacturing and unnecessary inventory. This bespoke approach not only streamlines the production process but also minimizes the costs associated with excess materials and discarded parts, ultimately leading to a leaner operation.

Moreover, the precise specifications of custom machined bearings can lead to improved performance and longevity in applications. This tailored fit reduces the likelihood of breakdowns and maintenance issues, thereby further lowering operational costs over time. When businesses invest in non-standard bearings that match their specific requirements, they are not just making a purchase; they are enhancing their efficiency, refining their resource management, and fostering a sustainable approach that can lead to long-term savings and environmental benefits.

Top 5 Benefits of Non Standard Bearings Custom Machining

Market Demand Insights: The Growing Trend of Custom Machined Bearings in Various Industries

The global demand for custom machined bearings is witnessing significant growth across various industries. With the plain bearing market projected to increase from USD 13.5 billion in 2025 to USD 23.9 billion by 2035, the opportunities for businesses to leverage non-standard bearings and custom machining services are immense. Companies are gradually recognizing that tailored solutions can enhance operational efficiency and reduce production costs, aligning with the overall trend of personalization in manufacturing.

As industries evolve, the versatility and adaptability of custom machined bearings become essential. Businesses can benefit from improved performance characteristics that suit unique applications, thus gaining a competitive edge. In the construction sector, for instance, the burgeoning global construction anchors market, anticipated to reach USD 5.65 billion by 2034, underscores the necessity for exceptional bearing solutions tailored to meet specific construction demands.

Tips: When considering custom machined bearings, assess the specific needs of your application to determine the best materials and designs. Collaborating with experienced machinists can help navigate the complexities of customization, ensuring you address potential challenges before they arise. Additionally, staying informed about market trends will enable your business to leverage opportunities promptly, fostering growth and innovation in your operations.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us