| 1. High Precision |

Reduces errors in assembly and increases product quality. |

Enhances overall production reliability. |

Up to 2 hours per shift. |

| 2. Durability |

Longer lifetime reduces frequency of replacements. |

Decreases maintenance time and costs. |

1 hour per week. |

| 3. Reduced Friction |

Improved movement efficiency with less energy consumption. |

Lower operational costs. |

Up to 1 hour per day. |

| 4. Easy Installation |

Quick setup minimizes downtime during production. |

Increases workflow efficiency. |

30 minutes per installation. |

| 5. Temperature Resistance |

Withstands high temperatures reducing failure rates. |

Enhances reliability in adverse conditions. |

1 hour per week in extreme conditions. |

| 6. Proven Performance |

Recognized reliability leads to confident procurement decisions. |

Reduces risks in production. |

1 hour per month. |

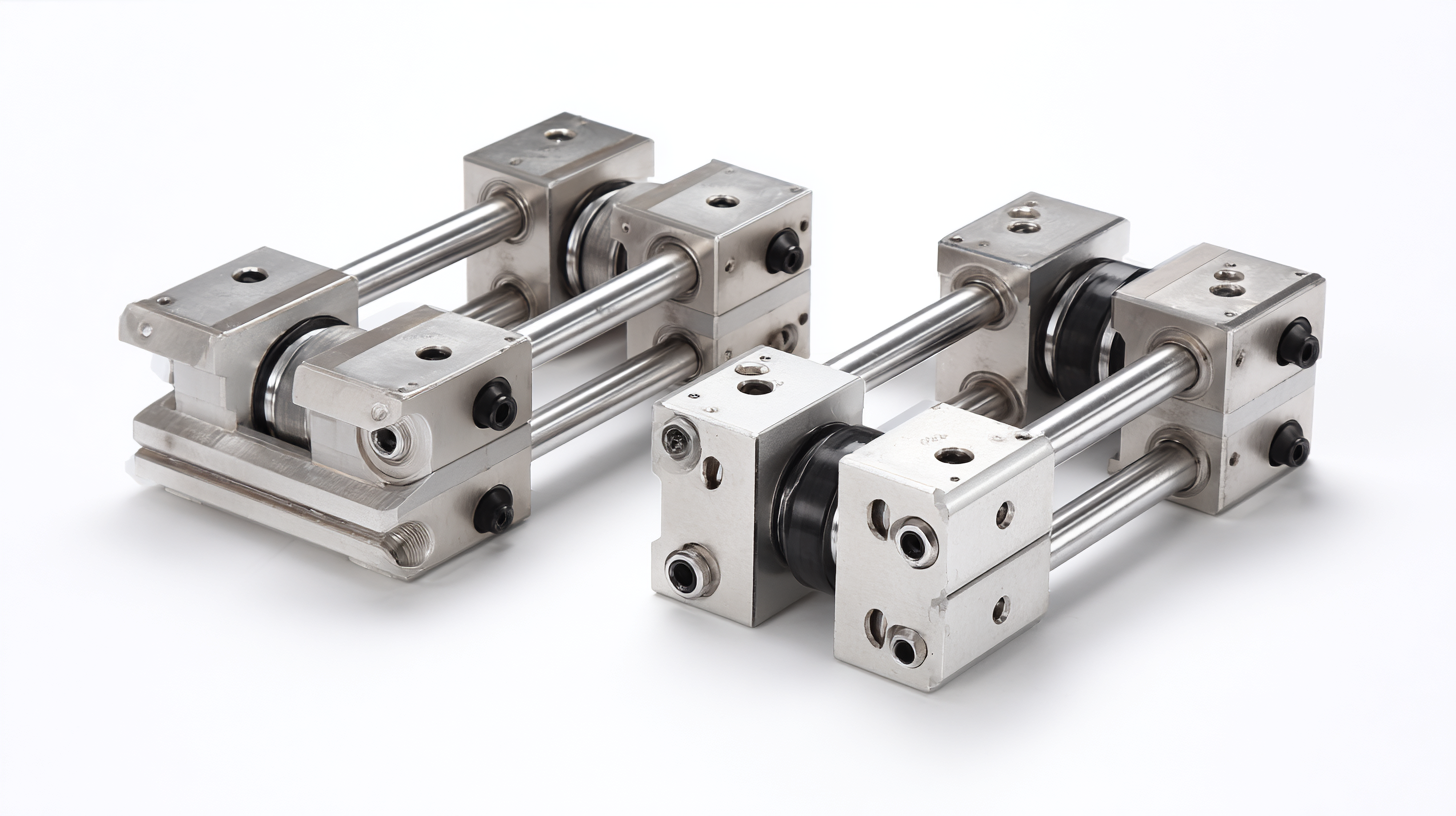

| 7. Variety of Sizes |

Availability of various sizes fits multiple applications. |

Customizable solutions for enhanced productivity. |

Varies by project. |

| 8. Bulk Ordering Benefits |

Cost savings from purchasing in bulk. |

Reduces overall procurement costs. |

N/A. |

| 9. Enhanced Load Capacity |

Higher load capacities increase production capability. |

Enables larger workloads. |

Varies by usage. |

| 10. Improved Consistency |

Consistent performance across operations. |

Supports stable output quality. |

1 hour per day. |

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us