Top Ceramic Hybrid Bearings Supplier What to Look For?

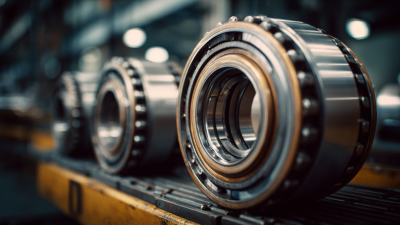

In today's industrial landscape, selecting the right Ceramic Hybrid Bearings Supplier is crucial. These bearings are known for their reduced friction, increased lifespan, and superior performance. According to a recent industry report, the global market for ceramic hybrid bearings is projected to grow by 6% annually. This rise is driven by their applications in aerospace, automotive, and medical devices.

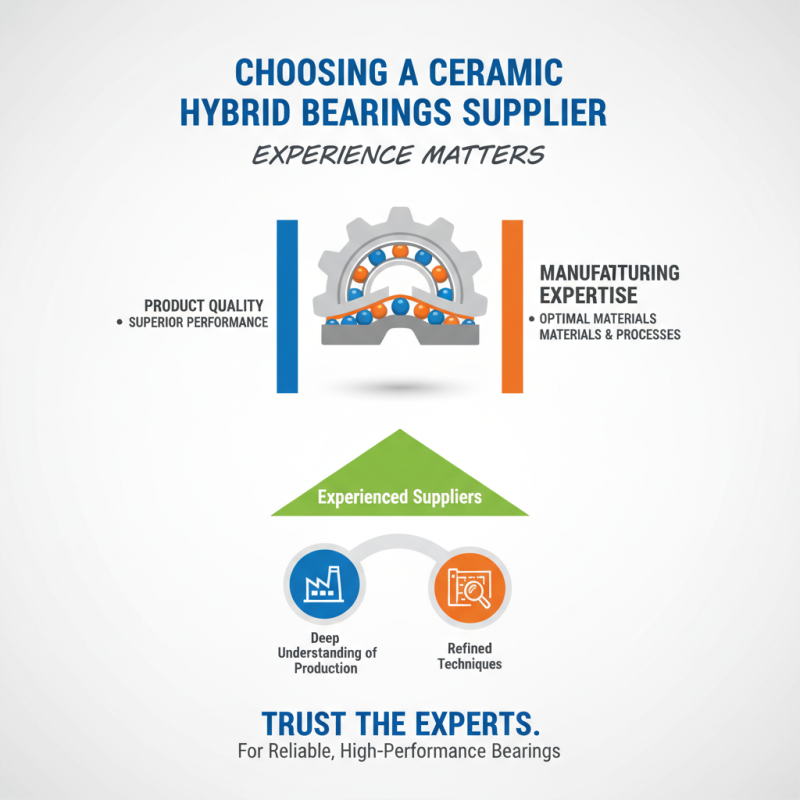

When evaluating suppliers, it’s essential to consider factors beyond just price. Quality assurance processes and material sourcing can greatly affect performance. Suppliers with a solid reputation often invest in state-of-the-art technology. However, not all suppliers meet these standards. Some may cut corners, leading to inferior products.

Industry professionals emphasize the importance of understanding a supplier’s track record. Certifications and customer reviews can provide valuable insights. Yet, relying solely on these factors may lead to missed opportunities. Assessing a supplier’s innovation capabilities is equally important for future needs. Selecting a Ceramic Hybrid Bearings Supplier requires thorough research and critical thinking to ensure optimal performance.

Top Ceramic Hybrid Bearings Supplier: Key Industry Trends and Data

In the growing market of ceramic hybrid bearings, several trends stand out. The global ceramic hybrid bearings market is predicted to reach $1.5 billion by 2025. This reflects a compound annual growth rate (CAGR) of 7.3% from 2020. Companies are increasingly focusing on innovations in materials and technology. Lightweight and high-strength materials are more common now.

Ceramic hybrid bearings offer advantages like reduced friction and improved wear resistance. They effectively operate in extreme temperatures. Thus, aerospace and automotive sectors are adopting them more frequently. Reports indicate that 45% of manufacturers are transitioning to these advanced bearings for better performance. However, the cost of production can be high, limiting widespread adoption. Manufacturers must balance this aspect while improving efficiency.

With sustainability becoming a priority, suppliers are exploring eco-friendly options. Recent studies showed that 60% of consumers prefer products with a lower environmental impact. Still, suppliers need to adapt to rapidly changing demands. The challenge lies in keeping up with technological advancements while managing production costs. The future of ceramic hybrid bearings will largely depend on how these suppliers respond to evolving market needs.

Top Ceramic Hybrid Bearings Supplier: Key Industry Trends and Data

| Dimension |

Value |

| Material Used |

Ceramic and Steel |

| Load Capacity (kg) |

1000 kg |

| Operating Temperature (°C) |

-40 to +120 |

| Speed Limit (RPM) |

50000 RPM |

| Market Growth Rate (2023) |

8.5% |

| Key Application Areas |

Aerospace, Automotive, Industrial Equipment |

| Average Life Span (hours) |

20000 hours |

Understanding the Composition of Ceramic Hybrid Bearings for Enhanced Performance

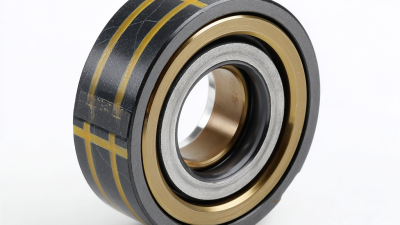

Ceramic hybrid bearings are designed for superior performance. They combine ceramic balls with steel races, creating a unique synergy. The ceramic material offers lower friction than steel, which enhances efficiency. This design leads to longer service life and reduced maintenance costs.

The composition greatly impacts the overall performance. Ceramic provides excellent hardness and wear resistance. However, not all ceramics are created equal. Some may lack the durability required for high-load applications. It's important to analyze the specific materials used in the bearings. Look for detailed specifications that mention the grade of ceramics.

While these bearings offer impressive advantages, they are not suitable for every situation. In environments with extreme temperatures, ceramic hybrid bearings might not perform optimally. Users should think carefully about their applications. A mismatch can lead to underperformance and costly repairs. Evaluate both your needs and the bearing’s capabilities to ensure the best choice.

Evaluating Supplier Reliability: Certifications and Quality Standards in Bearings

When selecting a ceramic hybrid bearings supplier, evaluating their reliability is crucial. A reliable supplier should have relevant certifications and adhere to quality standards recognized in the industry. Certifications like ISO 9001 indicate that manufacturers follow rigorous quality management systems. In a report by the American Society for Testing and Materials, almost 45% of bearing failures stem from poor materials or manufacturing processes. Opting for certified suppliers mitigates such risks.

Quality standards help ensure consistent performance. Suppliers should adhere to ASTM and ISO standards for material selection and testing processes. A recent study highlighted that bearings manufactured under strict quality guidelines can enhance operational efficiency by up to 30%. It’s essential to verify how a supplier achieves these standards. Asking for documentation can reveal gaps in their processes. It’s common for companies to overlook this step, ultimately affecting performance.

Certifications may seem impressive, but real quality lies in production practices. Some suppliers may possess certifications without robust quality control systems. This discrepancy often results in subpar products. Quality checks should cover everything from raw material sourcing to final testing. Without this, even certified suppliers can deliver unreliable bearings. Make informed choices to foster long-term reliability in your operations.

Price vs. Quality: How to Assess Value in Ceramic Hybrid Bearings Market

When assessing value in the ceramic hybrid bearings market, consider both price and quality. Recent industry reports indicate that high-quality hybrid bearings can improve performance by up to 30%. However, premium options often come with higher prices. Balancing cost and durability is crucial for manufacturers.

Tip: Explore multiple suppliers to compare pricing structures. Some manufacturers offer bulk discounts, which can significantly reduce overall costs. Often, lower-priced options may compromise quality. Ensure you check certification and material specifications to avoid unexpected failures.

It's essential to also evaluate the long-term performance of ceramic hybrid bearings. Some may show great initial performance but deteriorate faster under stress. A thorough analysis can reveal the total cost of ownership, helping you make informed decisions. Don't overlook warranty and support from suppliers either.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us