How to Choose the Best Deep Groove Ball Bearings Wholesale?

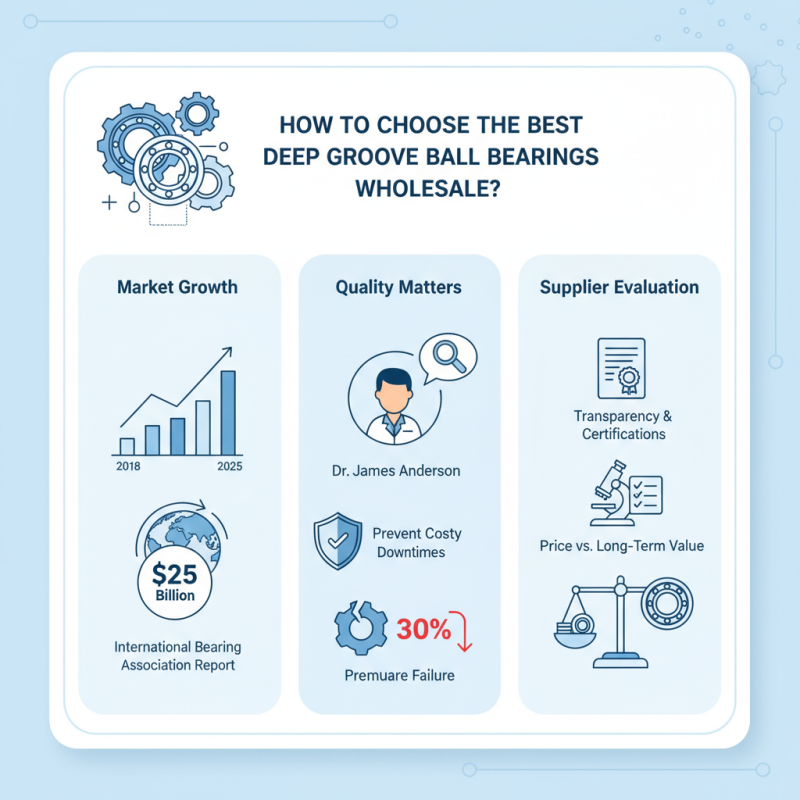

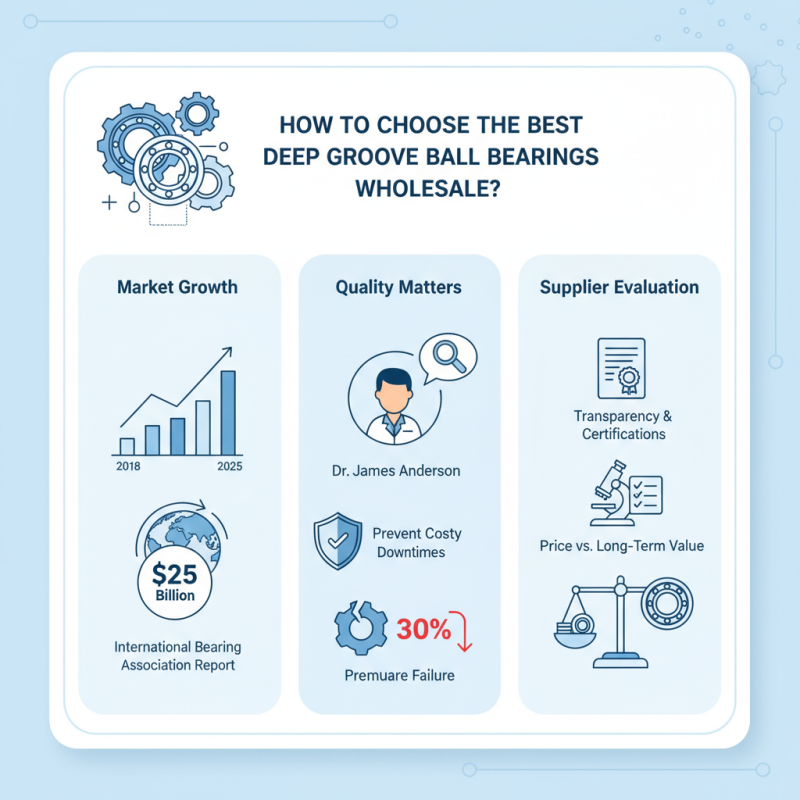

In the realm of industrial components, choosing the right "Deep Groove Ball Bearings Wholesale" can significantly affect equipment longevity and performance. According to a report by the International Bearing Association, the ball bearing market is projected to reach $25 billion by 2025, indicating robust growth in demand. Experts stress the importance of quality, with Dr. James Anderson, a renowned bearing specialist, stating, “Quality selections in bearings can prevent costly downtimes.”

When evaluating suppliers, consider various factors. A trusted supplier should offer transparency about their product's origins and certifications. Focused testing and quality control are essential to ensure reliability and performance. An unsettling statistic reveals that approximately 30% of bearings fail prematurely due to poor manufacturing practices.

While low prices can be tempting, they often lead to compromises in quality. It's crucial to weigh short-term savings against potential long-term costs. A discerning approach is required to navigate the landscape of "Deep Groove Ball Bearings Wholesale." This careful consideration can lead to successful partnerships and enhanced operational efficiency.

Understanding Deep Groove Ball Bearings and Their Applications

Deep groove ball bearings are versatile components widely used in various machinery. They are designed to accommodate radial and axial loads, making them suitable for both electric motors and automotive applications. The simplicity of their structure enhances their reliability. However, choosing the right bearing can be tricky.

Various factors influence the selection process. Load capacity, speed ratings, and size are critical aspects. If a bearing is too small, it may lead to premature failure. Conversely, selecting an oversized bearing could increase costs unnecessarily. It's essential to evaluate specific applications, as what works for one machine may not suit another.

Understanding the operating environment is also crucial. For instance, high temperatures or exposure to moisture can impact performance. Some bearings are better suited for harsh environments, while others may fail quickly. Researching material types and coatings can help avoid complications later. Balancing these considerations with cost and availability is key in making an informed decision.

Factors to Consider When Selecting Deep Groove Ball Bearings

When choosing deep groove ball bearings, several factors play a crucial role. Material quality is essential. High-grade steel typically offers better load capacity and longevity. Look for bearings that withstand corrosion, especially in harsh environments. This can enhance their lifespan significantly.

Another important aspect is the bearing size. Ensure that the inner and outer diameters fit perfectly with your application. Incorrect sizing can lead to premature failure. Also, consider the noise level. Some bearings operate quietly, while others may produce more sound. If noise is a concern, test samples to find the right fit.

Lastly, think about the supplier's reputation. Not all wholesalers provide the same level of quality. Some may deliver inconsistent products, which could cost more in the long run. Don't rush the decision. Take time to review customer feedback and warranty offers. Remember, the right choice today can save issues in the future.

How to Choose the Best Deep Groove Ball Bearings Wholesale? - Factors to Consider When Selecting Deep Groove Ball Bearings

| Dimension (mm) |

Load Capacity (kg) |

Speed Rating (RPM) |

Material |

Noise Level (dB) |

| 6000 (10x26x8) |

10 |

30000 |

Steel |

25 |

| 6201 (12x32x10) |

15 |

25000 |

Ceramic |

20 |

| 6302 (15x42x13) |

25 |

20000 |

Stainless Steel |

30 |

| 6404 (20x42x12) |

30 |

15000 |

Steel |

28 |

Evaluating Wholesale Suppliers for Quality Assurance

When evaluating wholesale suppliers for deep groove ball bearings, quality assurance is crucial. A report by the Market Research Future suggests that the ball bearing market will grow significantly, reaching an estimated value of $25.2 billion by 2026. This indicates a strong demand for quality products that can withstand various industrial applications.

Tips: Always check the certifications of suppliers. Quality management systems like ISO 9001 can be a good sign. Also, consider suppliers that provide detailed product specifications.

Beyond certifications, consider the supplier’s track record. Look for customer reviews and case studies to gauge reliability. A report from Research and Markets found that 18% of manufacturers faced issues with subpar bearings affecting operational efficiency. This highlights the importance of assessing quality before making a purchase.

Tips: Request samples to test performance. Do not rely solely on promises; tangible results matter. Engage with your supplier about their sourcing and manufacturing processes. Understanding their supply chain can reveal commitment to quality.

Comparing Pricing and Value in Wholesale Purchases

When considering wholesale deep groove ball bearings, pricing is a crucial factor. The global bearings market was valued at approximately $76 billion in 2020, and experts expect it to grow by 5% annually. However, price discrepancies can be vast among suppliers. Some offer lower rates due to reduced quality, while others provide premium products at a higher cost. This raises an important question: how can one assess value in such variability?

Quality inspection reports indicate that performance can drop significantly if materials are subpar. Studies from industry analysts show that 70% of equipment failures are attributed to bearing issues. This statistic highlights the need for careful selection, even at a wholesale level. Buying cheaper versions may lead to increased maintenance costs in the long run. Evaluating suppliers based on their track records and asking for sample products can mitigate risks.

Another aspect to weigh is long-term value versus upfront cost. While a lower price may seem appealing, it could lead to more frequent replacements and downtime. In fact, investing in higher-quality bearings could enhance overall operational efficiency. It's wise to remember that the cheapest option isn’t always the best one.

Comparing Pricing and Value of Deep Groove Ball Bearings

This chart compares the pricing and value rating of different qualities of deep groove ball bearings. The "Price per Unit" shows the cost in dollars, while the "Value Rating" represents the perceived value on a scale from 1 to 10. This information can guide buyers in making informed wholesale purchases.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us