How to Choose Energy Efficient Bearings for Maximum Performance and Cost Savings

In the quest for optimized performance and cost savings, selecting the right components is essential, and bearings are no exception. With an increasing focus on energy efficiency in various industries, the importance of making informed choices cannot be overstated.

This blog, titled "How to Choose Energy Efficient Bearings for Maximum Performance and Cost Savings", serves as your comprehensive Energy-Efficient Bearing Selection Guide.

It delves into the key factors to consider, such as load capacity, material composition, and lubrication methods that enhance energy efficiency. By understanding these aspects, engineers and procurement specialists can make smarter decisions that not only align with sustainability goals but also contribute to reducing operational costs.

Prepare to explore how the right bearing choices can lead to substantial improvements in performance while also being kinder to the planet.

Understanding Energy Efficiency in Bearings

When selecting bearings for your machinery, understanding energy efficiency is crucial not only for performance but also for significant cost savings. Energy-efficient bearings are designed to minimize friction, which in turn reduces heat generation and energy consumption. This improvement in efficiency can lead to extended service life and lower operating costs, making it a wise investment for any business.

Tip: Consider the type of grease used in your bearings. High-quality lubricants can significantly reduce friction and improve energy efficiency. Regularly monitor the lubrication condition to ensure optimal performance.

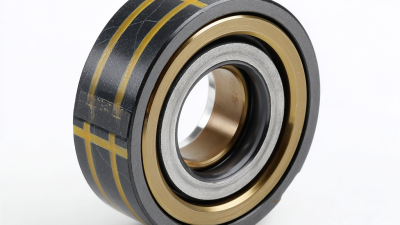

Moreover, the selection of materials affects the energy efficiency of bearings. Advanced materials such as hybrid or ceramic components can provide lower friction coefficients than traditional steel bearings. Choosing the right bearing material for your application can enhance overall efficiency and longevity.

Tip: Consult with a bearing manufacturer to select the best material suited for your specific operational conditions, which could lead to substantial long-term savings.

Key Factors to Consider When Selecting Bearings

When selecting energy-efficient bearings, several key factors must be considered to ensure maximum performance and cost savings. Firstly, the type of bearing material plays a crucial role in energy efficiency. According to a report by the American Bearing Manufacturers Association (ABMA), bearings made from high-performance polymers can reduce friction by up to 50% compared to traditional steel bearings. This significant reduction in friction not only enhances energy efficiency but also prolongs the lifespan of the bearing, leading to lower maintenance costs over time.

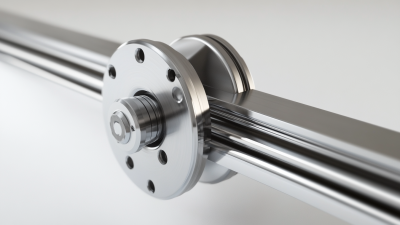

Another vital consideration is the bearing design and lubrication type. Studies indicate that optimized bearing designs, such as angular contact or deep groove designs, can improve load distribution and minimize energy losses. Furthermore, utilizing advanced lubricants—specifically, those with lower viscosity—can also contribute to enhanced performance. According to the International Journal of Thermal Sciences, proper lubrication can improve energy efficiency by as much as 20%. By carefully evaluating these factors and selecting the appropriate bearings, businesses can achieve substantial operational savings and promote sustainable practices.

Evaluating the Impact of Bearing Materials on Performance

When selecting energy-efficient bearings, the choice of materials plays a crucial role in maximizing performance while minimizing costs. Different materials exhibit distinct properties that can significantly affect the operational efficiency of bearings. For example, steel bearings are widely used due to their strength and reliability, but alternatives like ceramic and polyamide can provide enhanced performance in specific applications.

Ceramic bearings are known for their lightweight characteristics and reduced friction, which can lead to higher energy savings and longer service life under high-speed conditions.

Additionally, the lubrication compatibility of bearing materials is another important factor to consider. The interaction between the bearing material and the lubricant can influence the overall efficiency of the system. Materials that have lower thermal conductivity can retain lubrication better, reducing the need for frequent maintenance and contributing to long-term cost savings. By assessing the impact of various bearing materials on performance and energy consumption, businesses can make informed decisions that align with their operational goals and sustainability initiatives.

The Role of Lubrication in Enhancing Bearing Efficiency

Lubrication plays a critical role in enhancing the efficiency of energy-efficient bearings, directly affecting their performance and longevity. Recent studies have underscored the significance of lubrication in reducing friction and wear between moving parts. For instance, the use of amino acid ionic liquid lubricants not only improves tribological behavior but also augments adsorption on metal surfaces, leading to superior lubrication. This innovation can lead to significant cost savings over time, as reduced wear translates to longer service intervals and decreased maintenance.

Furthermore, advancements in nano-enhanced biolubricants offer exciting opportunities for improving bearing performance. These lubricants, enriched with nano additives, enhance heat transfer capabilities and reduce friction further, addressing the common issues faced in roller-bearing fatigue loads. By integrating these innovative lubrication solutions, industries can achieve greater energy efficiency, boost machinery reliability, and ultimately, enhance the overall output of their operations. In the quest for maximum performance, selecting the right lubricant is as crucial as choosing the appropriate bearings, setting the stage for a more sustainable manufacturing landscape.

Energy Efficiency of Different Bearing Types

Cost-Benefit Analysis of Energy Efficient Bearings

When evaluating the cost-benefit analysis of energy-efficient bearings, it's crucial to consider the long-term savings they provide against their initial investment. According to a report by the International Energy Agency, replacing standard bearings with energy-efficient models can lead to energy savings of up to 30%. While these bearings may have a higher upfront cost, typically 10-20% more than conventional options, the reduction in energy consumption can recoup this cost within a year or two, depending on operational conditions.

Additionally, energy-efficient bearings often extend equipment lifespan, resulting in lower maintenance costs and reduced downtime. The Machinery Lubrication Magazine highlights that companies can expect maintenance savings of around 25% when using high-performance bearings. This translates into not just financial savings but also improves operational efficiency and productivity. By integrating energy-efficient bearings into their machinery, companies can achieve a dual benefit: significant cost savings and a positive environmental impact, aligning with global sustainability goals.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us