How to Choose the Right Tapered Roller Bearings Supplier for Your Needs

In today’s competitive manufacturing landscape, selecting the right Tapered Roller Bearings Supplier is critical for ensuring operational efficiency and product reliability. These bearings play an essential role in various applications, providing support for both radial and axial loads, and their performance can significantly impact the durability of machinery. According to a recent report by the Global Bearings Market Analysis, the tapered roller bearings segment is anticipated to grow at a compound annual growth rate (CAGR) of 6.4% over the next five years, highlighting the increasing reliance on quality bearing solutions across industries.

Industry expert Dr. John Anderson, a leading authority in bearing technology, emphasizes, “Choosing the right supplier can make the difference between enhanced performance and frequent machinery failures.” With an expanding range of manufacturers and distributors, it is crucial for businesses to evaluate potential suppliers meticulously. Factors such as product quality, technical support, and delivery reliability are paramount to meeting specific operational needs. Additionally, understanding a supplier's production capabilities and their commitment to innovation can provide valuable insights into their ability to adapt to changing market demands.

Therefore, as companies seek optimal performance and longevity in their machinery, a strategic approach to selecting a Tapered Roller Bearings Supplier is essential. It demands thorough research and a clear understanding of both the product and the relationship with the supplier to maximize operational success.

Understanding the Basics of Tapered Roller Bearings

Tapered roller bearings are essential components in various industrial applications, known for their ability to accommodate both radial and axial loads. These bearings consist of an inner ring, an outer ring, cones, and a cage, allowing for efficient motion and high load capacity. According to a report from MarketsandMarkets, the global tapered roller bearing market is projected to reach $12.5 billion by 2026, with a compound annual growth rate (CAGR) of 5.6%. This growth is largely driven by increasing demand in the automotive and manufacturing sectors, where reliability and performance are paramount.

Understanding the fundamentals of tapered roller bearings can significantly aid in selecting the right supplier. These bearings provide optimal performance in various conditions, including high-speed applications and those involving heavy loads. The ability to handle misalignment and shock loads further enhances their popularity. According to a study by Research and Markets, nearly 70% of machinery failures are attributed to bearing issues, emphasizing the need for quality sourcing. By focusing on the technical parameters, such as load ratings, material specifications, and design features, industries can make informed choices that enhance operational efficiency and reduce downtime.

Key Factors to Consider When Selecting a Supplier

When selecting a supplier for tapered roller bearings, it is essential to consider several key factors to ensure you meet your operational needs. First, assess the supplier's industry experience and technical knowledge. A supplier with a deep understanding of tapered roller bearings will not only offer high-quality products but can also provide valuable insights into the selection, application, and maintenance of these bearings based on your specific requirements.

Another critical factor is the supplier's manufacturing capabilities and quality assurance processes. Understanding the quality control measures in place, such as ISO certifications or adherence to recognized industry standards, can help ensure the reliability and performance of the bearings you acquire. Furthermore, checking their production capacity and lead times is vital, especially if your projects rely on timely delivery.

Lastly, consider the level of customer support and service the supplier offers. A responsive supplier that provides comprehensive technical support, after-sales service, and a clear warranty policy can make a significant difference in your long-term satisfaction and operational efficiency. Evaluating these factors thoroughly will help you choose a supplier that aligns well with your needs and contributes positively to your projects.

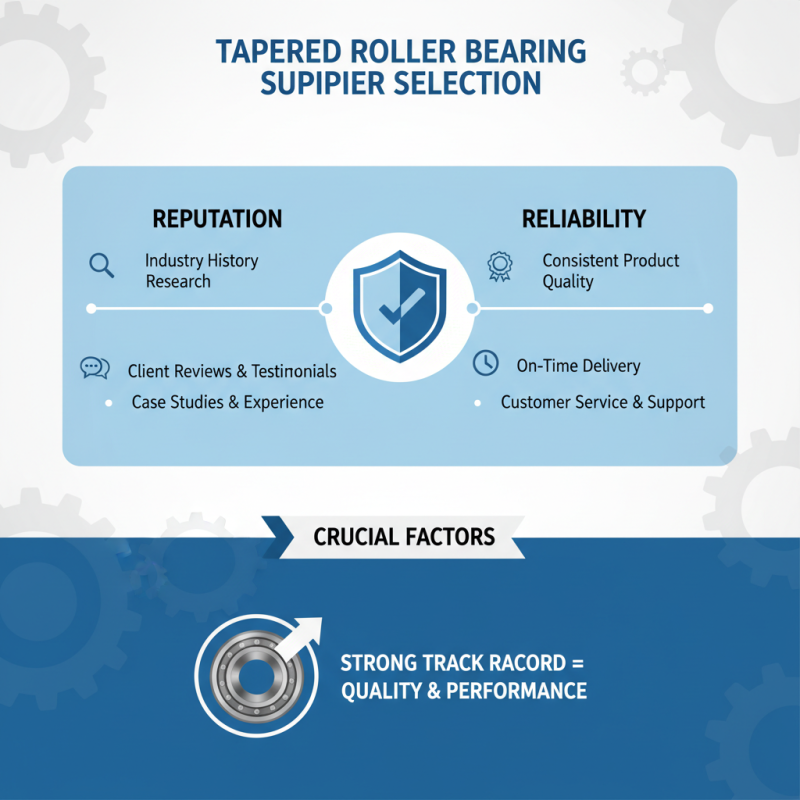

Evaluating Supplier Reputation and Reliability

When selecting a supplier for tapered roller bearings, evaluating their reputation and reliability is crucial. A supplier’s reputation can often reflect their commitment to quality and customer service. Start by researching their history in the industry. Look for reviews, testimonials, and case studies that demonstrate their experience and the satisfaction of previous clients. A supplier with a strong track record is more likely to provide products that meet your specifications and performance requirements.

Tips: Engage with industry forums or groups where professionals share their experiences with different suppliers. This can provide invaluable insights into the reliability of potential partners. Additionally, check if the supplier has any certifications or affiliations with industry organizations, as this can signify adherence to quality standards.

Another key aspect to consider is the supplier's responsiveness and customer support. A reliable supplier should be accessible for inquiries and able to provide timely updates regarding your orders. Establishing communication pathways can prevent misunderstandings and ensure that your needs are met efficiently.

Tips: Assess their support services by reaching out with questions or requests. A prompt and informative response can be indicative of their commitment to customer satisfaction and operational efficiency.

Assessing Product Quality and Specifications

When choosing a tapered roller bearings supplier, product quality and specifications are paramount factors to consider. The performance and longevity of the bearings directly impact the efficiency and reliability of machinery across various industries. According to a report by the International Organization for Standardization (ISO), over 30% of machinery failures are attributed to bearing quality issues. This statistic underscores the importance of selecting a supplier that adheres to stringent quality standards and specifications.

It's crucial to assess the material composition and tolerance levels of the tapered roller bearings. High-quality bearings are typically made from high-carbon chromium steel or similar materials, providing superior load capacity and wear resistance. Additionally, specifications such as size, load ratings, and operating temperature ranges should align with your specific application needs. A thorough examination of the supplier's product catalog and technical data sheets can provide insights into how well their offerings meet these requirements.

Tips: Before finalizing a supplier, consider requesting sample bearings to evaluate their performance in real-world situations. Also, verify the supplier’s certifications, such as ISO 9001, which can serve as evidence of their commitment to maintaining high-quality standards. Regularly consulting industry reports and performance reviews can also help in making informed decisions that align with your operational goals.

Exploring Pricing, Terms, and Customer Support Options

When selecting a tapered roller bearings supplier, understanding the pricing structure is crucial. According to the "Global Bearings Market Report 2022," a well-researched analysis indicates that the average price range for tapered roller bearings can vary significantly based on the supplier's quality and production capabilities, with costs typically falling between $1 to $10 per bearing. This variation is influenced by factors such as material quality, precision in manufacturing, and additional features like seals or shields. A comprehensive comparison of suppliers should not only focus on the base price but also consider the total cost of ownership, including potential shipping fees and lead times.

In addition to pricing, it is essential to evaluate the terms offered by potential suppliers. A recent study presented by the "Journal of Manufacturing Sciences" highlights that suppliers with more flexible terms, such as short lead times and favorable return policies, significantly enhance operational efficiency for their customers. Terms that facilitate just-in-time inventory practices or bulk purchasing discounts can lead to a more streamlined supply chain.

Customer support is another critical factor when assessing suppliers. Research from the "Industry Logistics Review" illustrates that suppliers who provide robust technical support and after-sales service improve customer satisfaction rates by over 30%. Look for suppliers offering clear communication channels, timely responses, and knowledgeable staff who can assist with installation, maintenance, and troubleshooting. This level of support can make a significant difference in ensuring operational continuity and minimizing unplanned downtimes.

How to Choose the Right Tapered Roller Bearings Supplier for Your Needs - Exploring Pricing, Terms, and Customer Support Options

| Supplier Location |

Pricing (per unit) |

Minimum Order Quantity |

Delivery Time |

Customer Support Availability |

| USA |

$25.00 |

100 units |

2 weeks |

24/7 |

| Germany |

€20.00 |

200 units |

3 weeks |

Business hours |

| China |

¥150.00 |

500 units |

4 weeks |

9 AM - 5 PM |

| Japan |

¥3000.00 |

50 units |

1 week |

24/7 |

| India |

₹1000.00 |

300 units |

5 weeks |

Business hours |

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us