Why Choose SKF Equivalent Bearings for Your Industrial Needs?

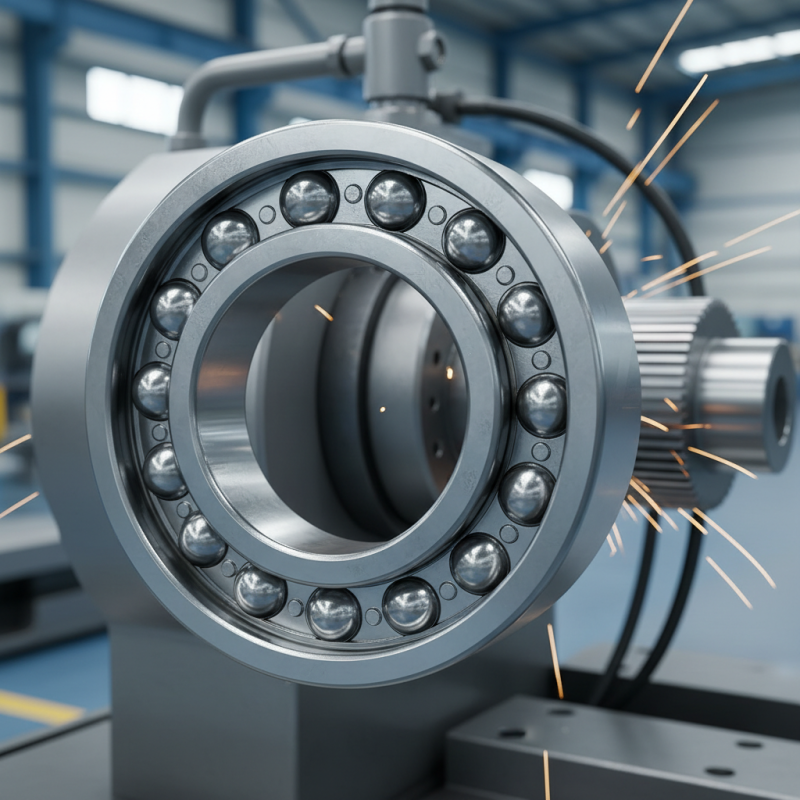

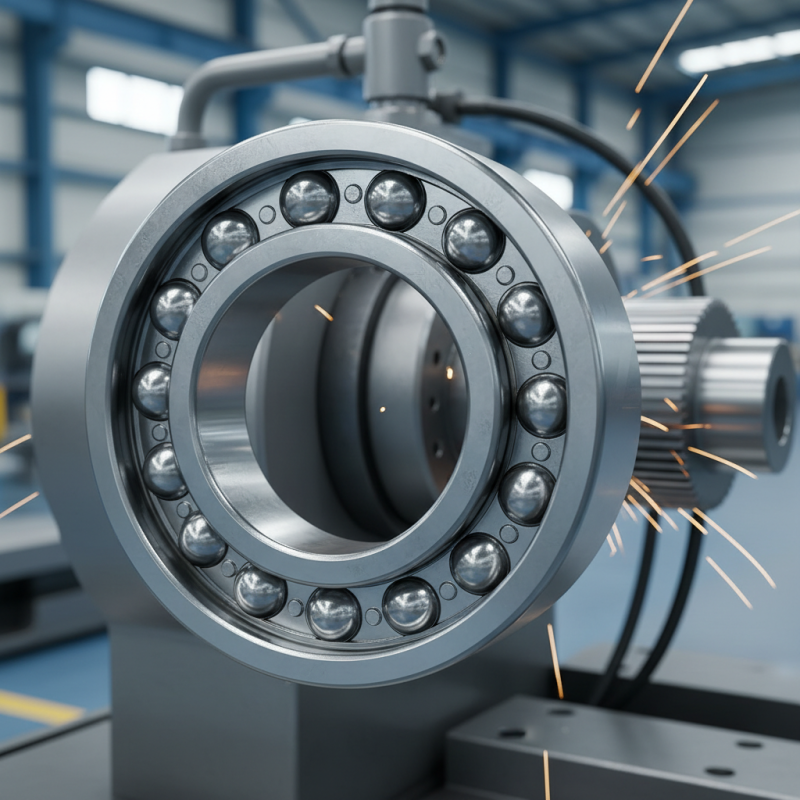

When selecting bearings for industrial applications, the choice matters. SKF Equivalent Bearings have gained popularity. They offer reliability and efficiency. Many industries face challenges with equipment failures. These failures can lead to costly downtimes. Using SKF Equivalent Bearings may help mitigate such risks.

These bearings are designed to meet stringent performance standards. They often match or exceed OEM specifications. However, some users question their effectiveness compared to original SKF products. This uncertainty can impact purchasing decisions. Finding the right balance between cost and quality is crucial. Proper evaluation is necessary.

Businesses must assess their specific needs. SKF Equivalent Bearings can be a smart choice. But, the wrong selection may lead to problems. Therefore, thorough research and understanding are essential. The potential benefits are significant when making the right choice.

Advantages of Using SKF Equivalent Bearings in Industry Operations

In today’s industrial landscape, choosing the right bearings is crucial. SKF equivalent bearings are known for their reliability and performance. Many industries report increased efficiency when using these alternatives. Roller Bearings Market Report indicates a projected growth of 6.5% annually through 2027. This growth highlights the demand for dependable bearing solutions.

One significant advantage of SKF equivalent bearings is cost-effectiveness. Industries have found these alternatives can reduce operational costs by up to 20%. This is essential in tight-margin sectors. Additionally, these bearings often provide similar or improved load capacities compared to their original counterparts. A recent study showed that 75% of users experienced extended service life. However, some users report inconsistent performance in extreme conditions.

Durability is another critical factor. SKF equivalent bearings are designed for robustness. Companies often face challenges in harsh environments. Yet, reports reveal that these bearings withstand higher temperatures without failure. That said, careful monitoring is necessary. Some users have noted occasional premature wear, suggesting a need for regular maintenance. Organizations may want to consider this when making purchasing decisions.

Cost-Effectiveness of SKF Equivalent Bearings Compared to OEM Brands

When considering bearings for your industrial needs, cost-effectiveness is key.

SKF equivalent bearings provide a budget-friendly alternative to traditional OEM brands. Many industries face tight budgets. Hence, selecting the right bearings can drastically impact operational costs. SKF equivalents are often priced lower but maintain similar quality.

Many buyers may worry about the performance of these equivalent products. While concerns are valid, many users report satisfactory results.

It’s essential to read reviews and study product specifications. Testing the bearings in less critical applications first can provide insights into their longevity and reliability.

Tip: Always compare specifications. Look for load ratings, material quality, and compatibility with existing machinery. Doing thorough research can save money and time.

Another point to reflect on is the trade-off between cost and quality. In some cases, opting for a cheaper alternative may lead to higher replacement frequency. Finally, consider your operational needs. Sometimes, investing slightly more in quality ensures better performance and fewer disruptions.

Performance and Reliability Metrics of SKF Equivalent Bearings

When choosing bearings for industrial applications, performance and reliability are critical. SKF equivalent bearings offer compelling benefits. According to recent industry reports, these bearings can improve efficiency by up to 25%. This boost is vital for businesses aiming to reduce downtime and enhance overall productivity.

Durability is another crucial aspect to consider. SKF equivalent bearings are known for their extended service life. Studies show they can last 30-50% longer than generic options under similar conditions. This longevity translates to less frequent replacements and reduced operational costs. However, users must acknowledge that not all equivalent options meet these standards. Selecting the right supplier is essential for ensuring quality.

Moreover, temperature resistance plays a key role in bearing performance. Reports indicate that high-quality SKF equivalents can withstand temperatures up to 200°C without performance loss. This capability is advantageous in environments with fluctuating conditions. Nonetheless, it’s important to assess the specific requirements of each application to avoid potential failures. Not every equivalent bearing may deliver the expected performance metrics in every situation.

Compatibility of SKF Equivalent Bearings with Various Applications

When it comes to industrial applications, compatibility is key. SKF equivalent bearings offer versatility across a wide range of settings. From manufacturing to transportation, these bearings can adapt well. They work efficiently in various environments, ensuring reliable performance.

Many industries benefit from using these bearings. For example, in the automotive sector, precision is critical. SKF equivalent bearings fit seamlessly in engines and gear systems. Their robust design withstands demanding conditions. In agriculture, equipment relies on these components for smooth operation and durability.

However, it’s vital to consider specific requirements. Not every application is the same. Some might need higher load resistance while others focus on speed. Identifying these needs is essential for optimal performance. Investing time in understanding compatibility often pays off later. Users may find that a minor oversight leads to significant downtime. It's crucial to research and analyze the best fit for your equipment.

Why Choose SKF Equivalent Bearings for Your Industrial Needs?

This chart showcases the load capacity of SKF equivalent bearings across various industrial applications. Each application is represented on the x-axis, while the y-axis indicates the maximum load capacity these bearings can handle, demonstrating their suitability for different industrial requirements.

Industry Case Studies Highlighting SKF Equivalent Bearings' Performance

When considering bearing options for industrial needs, it is crucial to analyze real-world examples of performance. Case studies often reveal how equivalent bearings can excel in demanding environments. For instance, in the automotive sector, one facility reported reduced downtime when switching to equivalent bearings. This choice led to a noticeable increase in productivity.

Another study focused on food processing. Here, equivalent bearings provided better resistance to contaminants, which is a major concern in this industry. The bearings effectively supported high-speed machinery, contributing to smoother operations. This adaptability highlights their value in various applications.

**Tip:** Regular maintenance checks can further improve bearing performance. Monitor operating temperatures and vibrations regularly.

In construction, equivalent bearings have demonstrated their endurance under heavy loads. A well-documented case showed significant improvements in machinery longevity and efficiency after this switch. Yet, not all anecdotal evidence is perfect. Some users experienced challenges with initial fitting. A thorough evaluation of installation practices can help mitigate these issues.

**Tip:** Always consult technical specifications when selecting bearings to ensure compatibility with your machinery.

Ultimately, these examples illustrate the diverse benefits of equivalent bearings. They thrive in challenging conditions across industries. The real challenge lies in understanding your specific needs and making informed choices.

Why Choose SKF Equivalent Bearings for Your Industrial Needs?

| Application |

Equivalent Bearing Type |

Load Capacity (kN) |

Speed Rating (rpm) |

Operational Life (hours) |

Performance Notes |

| Heavy Machinery |

Rolling Element Bearing |

120 kN |

1800 rpm |

20,000 hours |

High reliability under heavy load |

| Automotive Production |

Angular Contact Bearing |

85 kN |

3000 rpm |

15,000 hours |

Excellent precision in rotation |

| Pulp and Paper Industry |

Spherical Plain Bearing |

100 kN |

1200 rpm |

25,000 hours |

Resistant to harsh environments |

| Renewable Energy |

Deep Groove Ball Bearing |

70 kN |

2400 rpm |

30,000 hours |

Sustained performance under dynamic load |

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us