How to Choose the Right OEM Bearing Manufacturing Service for Your Business Needs

In today's highly competitive manufacturing landscape, selecting the appropriate

OEM Bearing Manufacturing Services is crucial for businesses aiming to optimize their supply chain efficiency and product quality.

According to a recent report by Allied Market Research, the global bearing market is expected to reach $120 billion by 2025, with a projected CAGR of 9.0% from 2018 to 2025.

This substantial growth emphasizes the importance of choosing the right manufacturing partner to meet specific business needs.

As companies increasingly seek to enhance their operational capabilities while minimizing production costs, aligning with a reliable OEM bearing manufacturer can lead to significant advantages.

Factors such as technological expertise, production scalability, and adherence to quality standards play a pivotal role in the decision-making process.

Understanding these elements is essential for businesses to leverage OEM bearing services effectively and gain a competitive edge in the market.

Assessing Your Business Requirements for OEM Bearings

When selecting an OEM bearing manufacturing service, it is crucial to start with a thorough assessment of your business requirements. According to a report by Markets and Markets, the global bearing market is expected to reach $92.2 billion by 2026, growing at a CAGR of 4.9%. This growth signifies the increasing complexity and specialization within the industry, making it vital to align your specific needs with the capabilities of potential manufacturers.

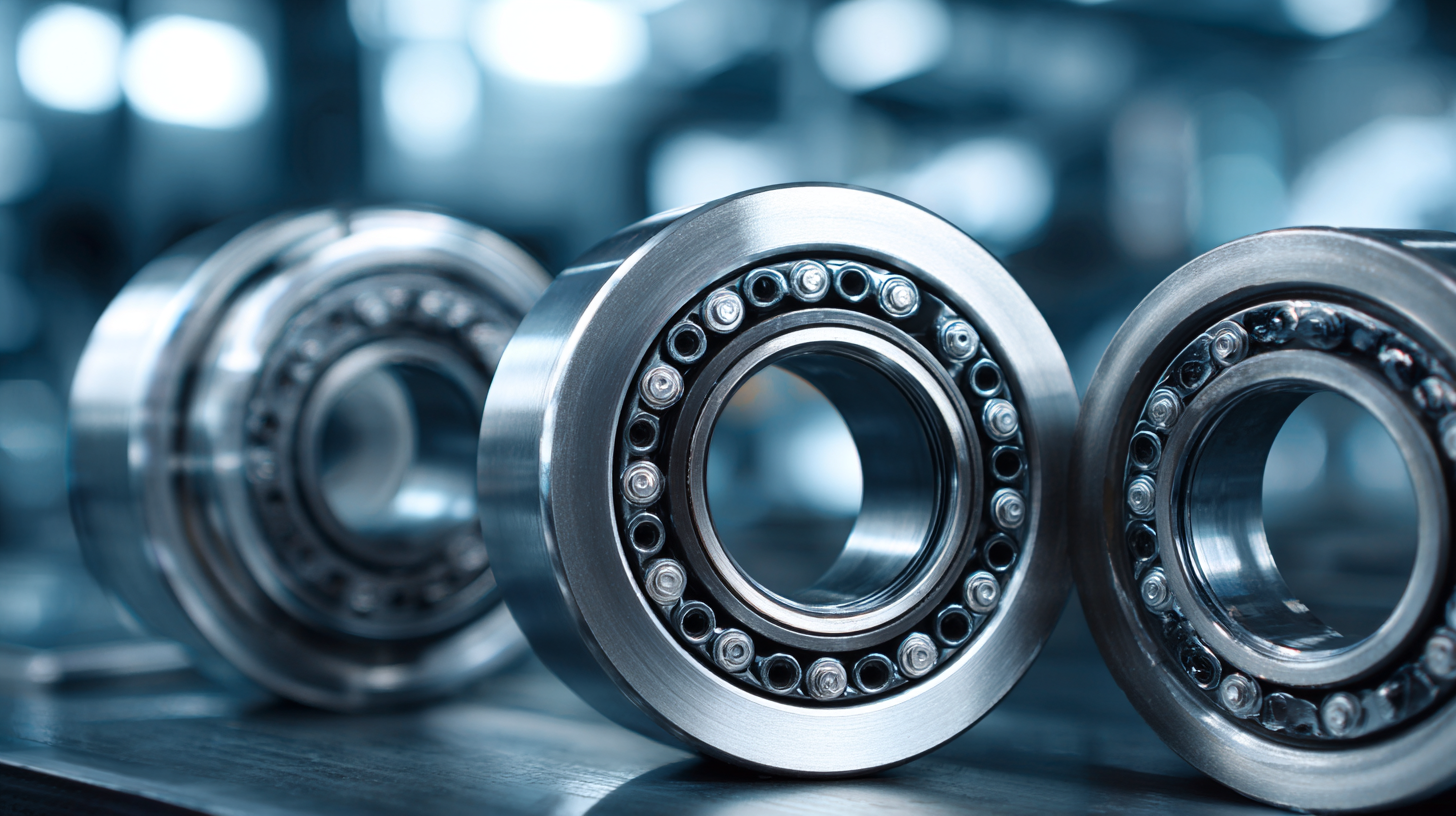

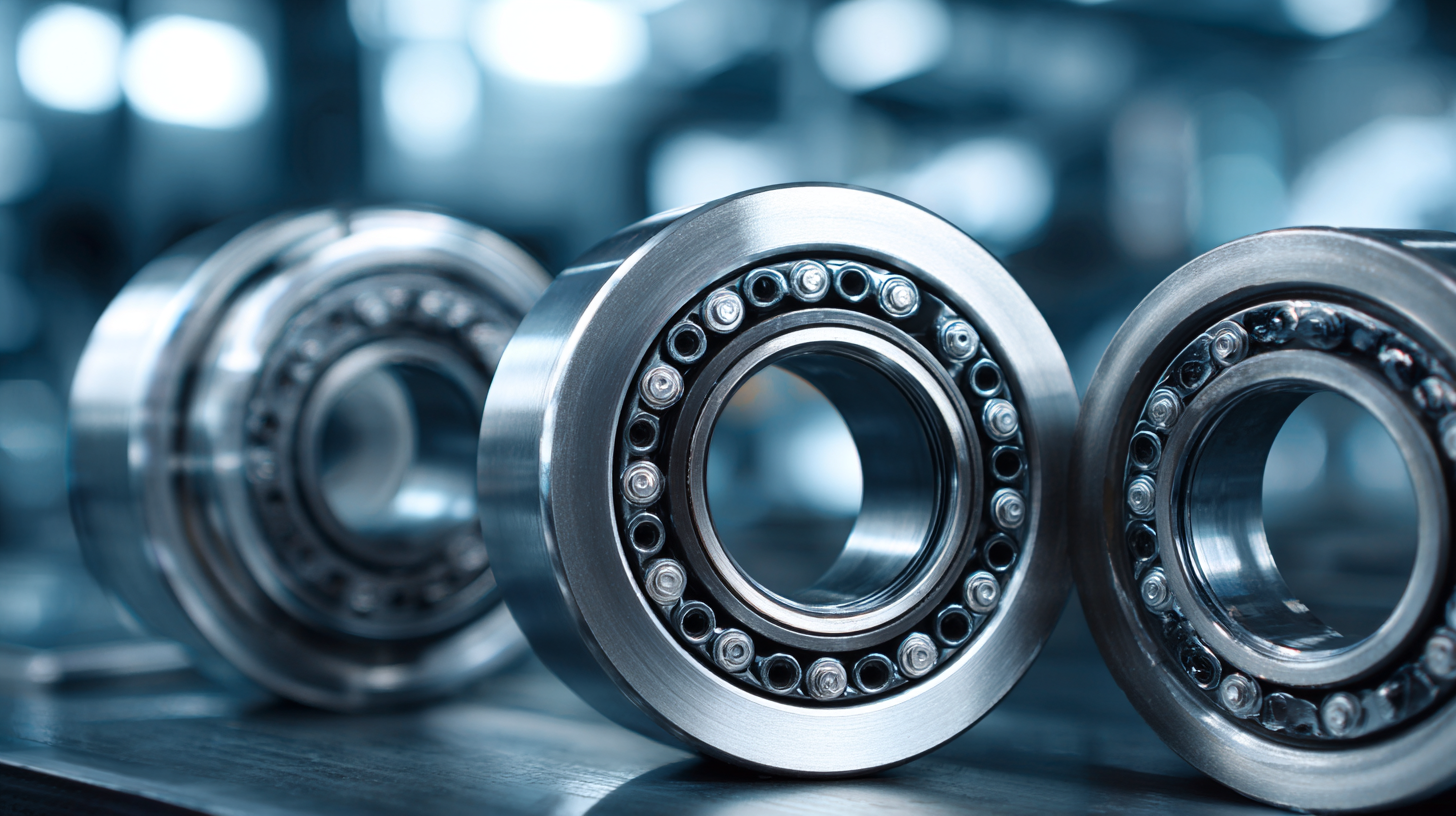

Understanding your operational demands—such as load capacity, speed, temperature range, and environmental considerations—will guide you in determining the most suitable bearing types for your applications. A survey by Grand View Research highlights that the automotive sector accounted for over 30% of bearing demand in 2022, emphasizing the need for manufacturers to be well-versed in industry-specific standards and regulations.

Collaborating with a supplier that not only manufactures high-quality bearings but also possesses expertise in your sector can significantly enhance production efficiency and reduce downtime. This tailored approach ultimately enables businesses to stay competitive in an ever-evolving marketplace.

Identifying the Key Factors in Bearing Manufacturing Services

When choosing the right OEM bearing manufacturing service for your business needs, it's essential to consider several key factors that can significantly impact your operations.

First, assess the manufacturer's production capacity. According to a recent report from the Bearing Manufacturers Association, the global bearing market is projected to reach $100 billion by 2025, with manufacturers scaling up their operations to meet the growing demand. Ensuring that a potential OEM partner can handle the volume you require is crucial for maintaining your supply chain integrity.

Another important factor is the technology and materials used in production. A study conducted by TechNavio highlights that advanced materials, such as ceramic and polymer composites, are becoming increasingly popular in bearing manufacturing due to their superior performance and durability. It's vital to partner with an OEM that invests in state-of-the-art technology and adheres to industry standards, as this will enhance product quality and longevity.

Finally, consider the manufacturer's experience and reputation in the field. Research indicates that companies with over a decade of experience in bearing manufacturing often demonstrate higher quality control standards and better customer service. A well-established OEM partner can not only provide reliable products but also valuable insights into industry trends and innovation, which can be instrumental for your business's growth.

Evaluating Manufacturer Credentials and Experience

When selecting an OEM bearing manufacturing service, evaluating the manufacturer's credentials and experience is essential to ensure that they can meet your business needs effectively. A manufacturer’s track record, including the length of time in the industry and their reputation among clients, can provide insight into their reliability and expertise. Look for certifications and standards compliance, which serve as indicators of quality assurance and commitment to excellence. Partnering with a manufacturer known for strong design practices can lead to innovative solutions that enhance product usability and functionality.

**Tips:**

1. Review case studies and client testimonials to gauge the manufacturer's past performance and capabilities. This can help determine if their experience aligns with your project requirements.

2. Inquire about their design and development processes, especially if sustainability factors are a priority for your business. Understanding how they incorporate eco-friendly practices can give you an edge in today's market, where consumers increasingly favor responsible manufacturing.

Choosing the right OEM bearing manufacturer is more than just a transaction; it’s about forming a strategic partnership that adds value to your operations and supports your long-term goals.

How to Choose the Right OEM Bearing Manufacturing Service for Your Business Needs

| Manufacturer Location |

Experience (Years) |

Certifications |

Production Capacity (Units/Month) |

Specialization |

| Asia |

15 |

ISO 9001, ISO 14001 |

50000 |

Automotive |

| Europe |

20 |

ISO 9001, IATF 16949 |

30000 |

Industrial |

| North America |

10 |

ISO 9001 |

20000 |

Aerospace |

| South America |

5 |

ISO 9001, AS9100 |

15000 |

Heavy Machinery |

Understanding Quality Control Measures and Standards

When selecting an OEM bearing manufacturing service, understanding the quality control measures and standards they implement is crucial for ensuring the durability and performance of your products. According to a report by Smithers, nearly 80% of failures in industrial applications are attributed to inadequate quality control during manufacturing. A reputable manufacturer should adhere to international standards such as ISO 9001 and ISO/TS 16949, which set benchmarks for quality management systems, focusing on continuous improvement and customer satisfaction.

Moreover, advanced quality control methodologies such as Six Sigma and Total Quality Management (TQM) can significantly enhance product reliability. A study by American Society for Quality highlights that organizations implementing these methodologies witness a 20-30% reduction in defects. Additionally, supporting data from the National Institute of Standards and Technology (NIST) indicates that robust quality control processes can lead to an increase in overall efficiency by up to 25%. Therefore, a thorough evaluation of the manufacturer's commitment to quality control not only safeguards your investment but also ensures that the bearings you procure will meet the demanding standards of your industry.

Comparing Cost-Effectiveness and Service Flexibility of Providers

When selecting an OEM bearing manufacturing service, assessing cost-effectiveness and service flexibility is crucial for your business's success.

Cost-effectiveness ensures that you are getting high-quality products at competitive prices, enabling you to maintain margins while meeting production demands.

It is essential to compare various providers to find the one that aligns with your budget constraints without compromising on quality.

The latest trends in manufacturing highlight that opting for providers that offer scalable pricing models can lead to significant savings, especially when your order quantities vary.

Service flexibility is equally important, especially in a dynamic business environment where needs can change rapidly.

A provider that adapts to your specific requirements—whether it involves customizations, quicker turnaround times, or varying order sizes—can greatly enhance your operational efficiency.

Just as businesses in different sectors find value in flexible service providers, bearing manufacturers who can accommodate changes in designs and quantities while maintaining reliability are valuable partners.

Thus, a thorough evaluation of both cost-effectiveness and service adaptability will ensure you choose a manufacturer that not only meets your immediate demands but also supports your long-term business goals.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us