How to Choose the Best Ceramic Hybrid Bearings Supplier?

Selecting the right Ceramic Hybrid Bearings Supplier is crucial for ensuring quality and performance. Mark Thompson, a leading expert in the field, emphasizes, "The right supplier can make all the difference in the longevity of your equipment." With numerous suppliers in the market, it’s vital to understand what sets them apart.

Evaluate the supplier's experience and reputation. Look for client reviews and case studies that demonstrate their capabilities. This information can provide insights into their reliability. Not all suppliers are created equal; some may promise high performance but fall short.

Additionally, consider the materials used in the bearings. Quality ceramics enhance durability and efficiency. A good supplier should transparently share details about their production processes. Reflect on your specific needs—an ideal supplier should understand your industry demands. Taking the time to research can lead to significant benefits.

Understanding Ceramic Hybrid Bearings: Benefits and Applications

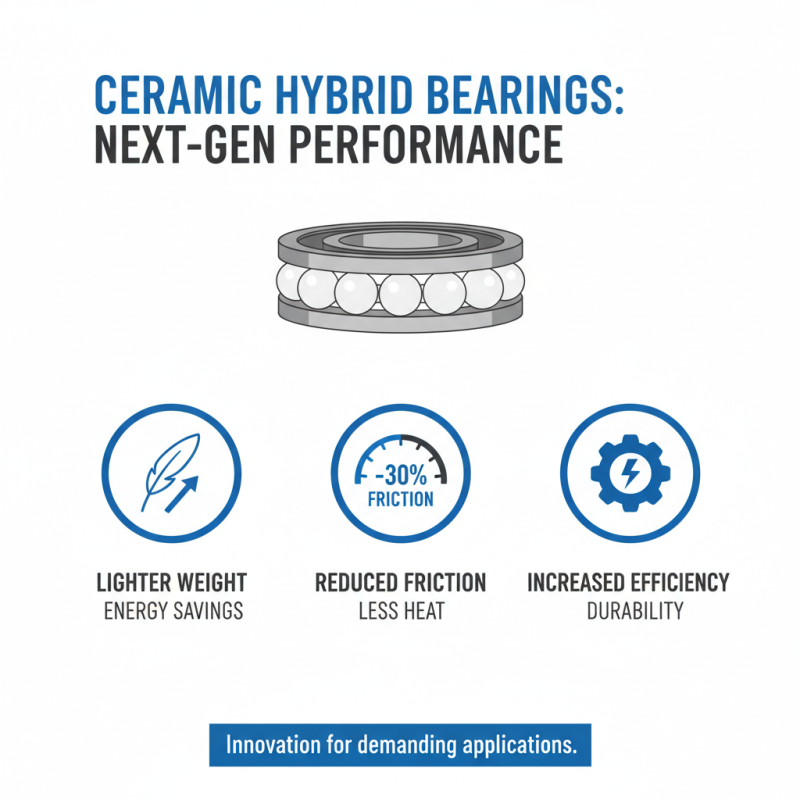

Ceramic hybrid bearings combine ceramic balls with steel races. This unique design offers several advantages in various applications. For instance, they are lighter than traditional bearings. This property can lead to energy savings. Research indicates that hybrid bearings can reduce friction by up to 30%. That means less heat generation during operation.

These bearings are ideal for high-speed, high-temperature environments. Industries like aerospace and automotive benefit significantly. They can withstand harsh conditions better than their all-steel counterparts. Additionally, ceramic materials are more resistant to corrosion and wear. This means increased lifespan and reduced maintenance costs. A recent industry report highlighted that using ceramic hybrid bearings can extend service life by 50% in certain settings.

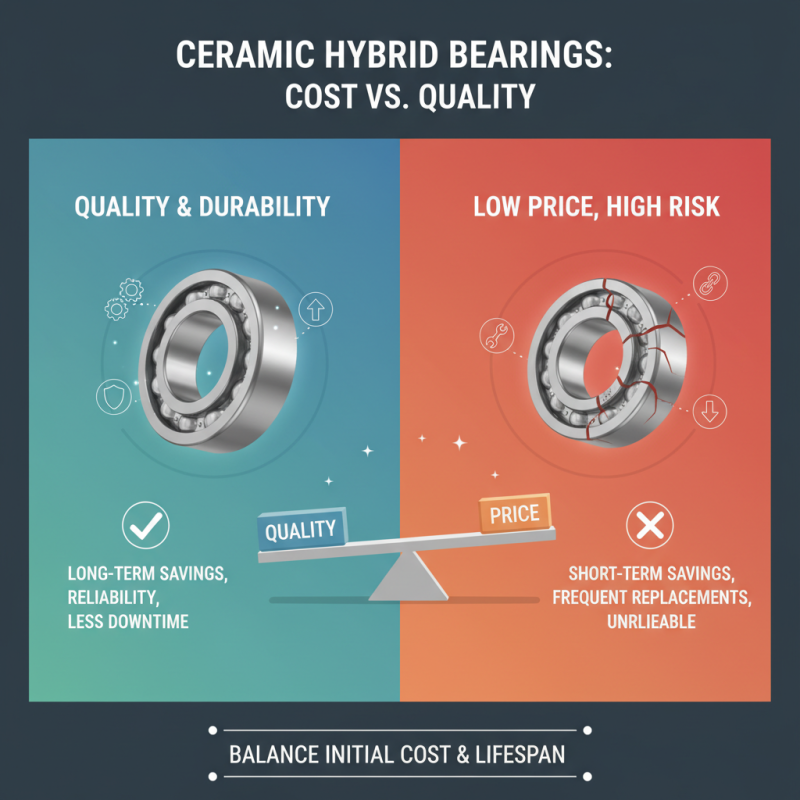

However, it's essential to consider potential downsides. Not all applications will benefit from hybrid materials. Cost is a factor, as they tend to be pricier upfront. Users must reflect on whether the long-term benefits outweigh initial investments. Therefore, evaluating specific needs and conditions is crucial when choosing ceramic hybrid bearings for optimal performance.

Key Factors to Consider When Selecting a Ceramic Hybrid Bearings Supplier

Choosing the right ceramic hybrid bearings supplier can significantly impact your operations. Several key factors come into play. Quality control is crucial. According to industry reports, 85% of bearing failures are due to poor manufacturing standards. Therefore, checking a supplier's certifications is essential. Look for ISO standards. Ensure their processes meet your expectations.

Another factor is the supplier's experience in the field. A supplier with over a decade of experience may better understand your needs. Reports indicate that experienced suppliers can reduce product lead times by up to 30%. However, don’t just rely on years in business. Examine their client feedback and case studies. Negative reviews should raise red flags.

Lastly, consider the supplier's ability to provide customized solutions. A one-size-fits-all approach often leads to inefficiencies. Some suppliers may resist customization, sticking to their standard offerings. This can limit your options down the line. Assess their willingness to adapt to specific requirements. It reflects their commitment to customer satisfaction.

How to Choose the Best Ceramic Hybrid Bearings Supplier?

| Criteria |

Importance |

Example Metrics |

Notes |

| Quality of Materials |

High |

Testing Procedures, Certifications |

Ensure compliance with industry standards. |

| Experience and Reputation |

High |

Years in Business, Client Testimonials |

Look for established suppliers with positive feedback. |

| Technical Support |

Medium |

Availability of Engineers, Customer Service Rating |

Responsive support can resolve issues faster. |

| Customization Options |

Medium |

Range of Custom Products Offered |

Choose suppliers who can meet specific needs. |

| Pricing |

High |

Competitive Pricing, Bulk Discounts |

Balance cost with quality to avoid cheap alternatives. |

| Delivery Times |

Medium |

Lead Time Estimates, Shipping Options |

Timely delivery is crucial for project schedules. |

Evaluating Supplier Performance: Quality Standards and Certifications

When selecting a supplier for ceramic hybrid bearings, assessing their performance is crucial. Start by examining quality standards. Look for suppliers who adhere to recognized industry guidelines. This ensures product reliability and durability. Certification can also be indicative of a supplier’s commitment to quality. ISO certifications are often essential in confirming that manufacturing processes meet international standards.

Beyond certifications, consider the supplier's history. Have they consistently delivered high-quality products? Customer testimonials can provide insight into their reliability. A supplier with a strong track record is likely to maintain quality over time. Pay attention to any complaints or issues raised by past clients. This reveals potential weaknesses in their operations.

Finally, do not overlook the importance of communication. A supplier that responds promptly and transparently can be a reliable partner. If they struggle to address concerns, it might reflect their overall performance. Remember, the right supplier not only meets standards but also actively works to improve.

Market Trends and Demand in the Ceramic Hybrid Bearings Industry

The ceramic hybrid bearings industry is experiencing notable growth. The global market is projected to reach $2 billion by 2025, according to recent reports. Increasing demand in sectors like automotive and aerospace contributes to this rise. These bearings offer durability and reduced friction, making them appealing.

Current trends indicate a shift towards lightweight materials and energy-efficient solutions. Many manufacturers are adapting to these demands. A study highlighted that about 45% of engineers prioritize performance over cost when selecting components. This willingness to invest can drive innovation. However, some suppliers struggle to meet quality standards consistently.

The demand for ceramic hybrid bearings is not uniform across industries. Some regions face supply chain challenges. This creates opportunities for local suppliers. Companies need to assess their options carefully. Balancing quality, reliability, and cost is crucial. Making informed decisions can help businesses thrive in this evolving market.

Market Trends in the Ceramic Hybrid Bearings Industry

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us