Top 10 Tips for Choosing the Best Wind Turbine Bearings Provider?

When selecting a Wind Turbine Bearings Provider, the choice can significantly impact your project. Bearing quality affects turbine performance and longevity. With many providers available, making the right decision can seem overwhelming.

Consider the experience of the provider. How long have they been in the industry? A provider with years of expertise often understands the complexities of wind turbine systems. Look for customer reviews and testimonials for insights. A strong reputation usually reflects reliable service and quality products.

It's also essential to evaluate material quality. What type of materials does the provider use? High-grade materials assure durability and efficiency. Remember, the lowest price does not always mean the best value. Sometimes, you might feel confused about balancing cost with quality. Be aware of your specific needs and ask questions. This can lead to better choices. Trust your instincts and do thorough research.

Understanding the Role of Bearings in Wind Turbine Performance

Bearings play a crucial role in wind turbines. They facilitate smooth movement of various components, including the rotor and generator. A malfunctioning bearing can lead to increased friction, resulting in energy loss and reduced efficiency. The right bearings ensure optimal performance and longevity of wind turbines.

Choosing the best provider for wind turbine bearings is essential. It's important to consider materials used. High-quality steel or advanced composites can offer better resistance to wear. Additionally, check lubrication options that maximize lifespan and reliability. A comparison of different providers may show significant variations in quality. Some offer extensive warranties, while others might not. This research can be time-consuming, yet worthwhile.

Lastly, understanding the environmental conditions where turbines operate is vital. Bearings must withstand temperature fluctuations and moisture. Some providers excel in adaptation to these conditions. However, not all meet the necessary criteria. Be prepared for questions regarding past performance records. A good provider should have a solid history with client feedback. This can help in making a more informed choice.

Top 10 Tips for Choosing the Best Wind Turbine Bearings Provider

Key Qualities to Look for in a Wind Turbine Bearings Provider

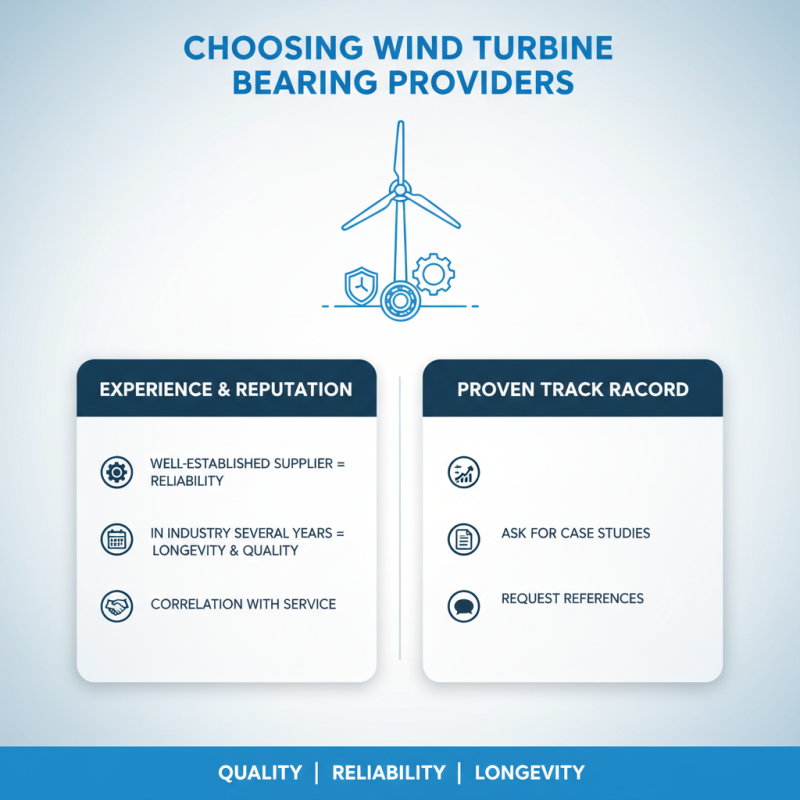

When selecting a wind turbine bearings provider, certain key qualities are crucial. Start by looking for experience in the industry. Providers with a solid track record often have valuable insights into the unique challenges of wind energy. This experience can translate into better product performance and more effective support.

Next, consider the quality of materials used. High-quality bearings are essential for longevity and efficiency. Ask about the materials and manufacturing processes. Transparency in these areas reflects a commitment to quality. A provider should be willing to share specifications and certifications that prove their products meet industry standards.

Customer service is another vital quality. A responsive team can assist during installation and maintenance. It's important they offer ongoing support to address any issues. Look for reviews or testimonials that highlight their communication skills. This aspect may seem minor but can significantly impact performance over time. A provider's dedication to customer relationships is often a good indicator of their overall reliability.

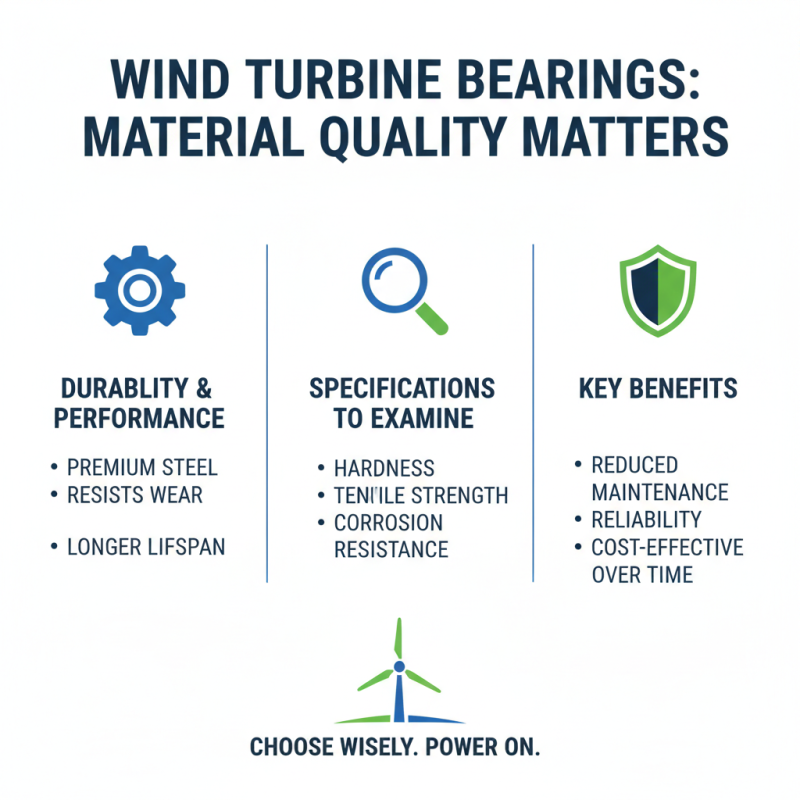

Assessing Material Quality and Manufacturing Standards

When choosing a wind turbine bearings provider, material quality is crucial. High-quality materials ensure durability and performance. Bearings made from premium steel often resist wear better than lower-grade alternatives. Examine the specifications carefully. Look for details on hardness, tensile strength, and corrosion resistance. These attributes directly affect the bearing's lifespan.

Manufacturing standards also play a significant role. It’s essential to check if the provider follows industry regulations. Certifications often indicate a commitment to quality. However, not all certifications are created equal. Some may be outdated or irrelevant. Research recent practices. Visit production facilities if possible. A transparent manufacturing process can reveal a lot about product quality.

While assessing these factors, it might be tempting to focus solely on cost. However, cheaper options may compromise longevity and efficiency. Consider the long-term implications. Investing in better materials can yield savings down the line. Balancing cost with quality requires careful thought. Reflect on your specific needs and operational conditions. Make informed decisions that align with your goals.

Considering Customer Support and Maintenance Services Offered

When selecting a wind turbine bearings provider,

customer support and maintenance services are crucial. You need a partner who can respond

quickly and effectively. Delays in communication

can lead to costly downtime. Ask about their

response times and availability.

Consider the maintenance services offered. Regular maintenance extends the life

of your bearings. Some providers may promise great support but lack comprehensive maintenance

plans. Verify if they have a proactive approach.

Scheduled check-ups can prevent unexpected failures.

Evaluate the training provided for support staff.

Knowledgeable staff can make a difference during emergencies. If they lack expertise,

solutions might come slowly. Documentation and resources should be

easy to access. You want to ensure that help is just a call away, even in a crisis.

Always look for transparency in their services. This

can tell you a lot about their reliability.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us