How to Choose Energy Efficient Bearings for Your Projects?

Choosing the right bearings is crucial in any project. Energy-efficient bearings can significantly enhance performance and reduce operational costs. This Energy-Efficient Bearing Selection Guide will help you navigate the complex landscape of bearing options.

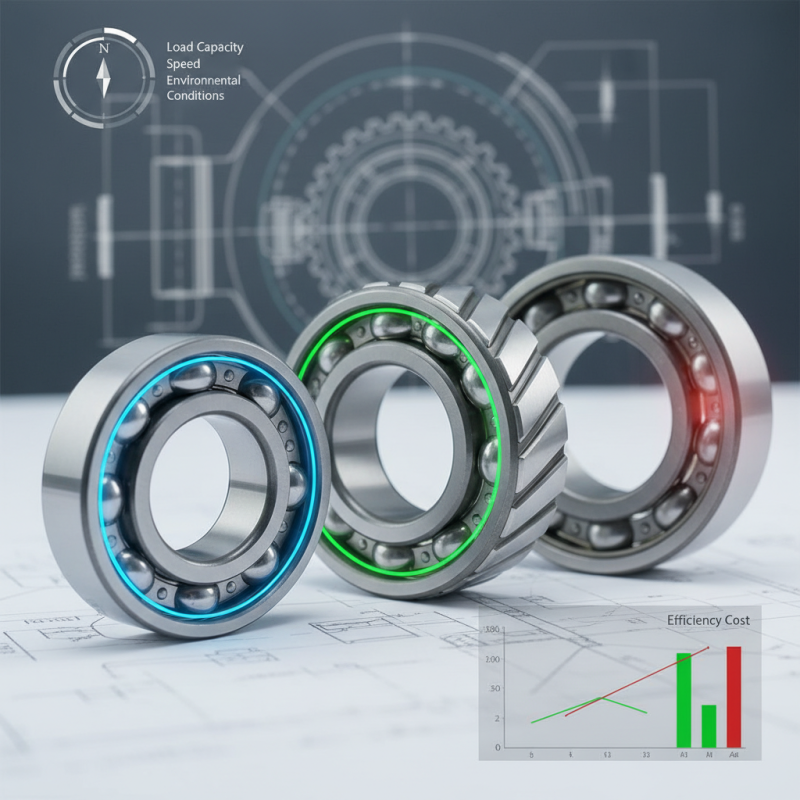

Consider the specific requirements of your application. Factors such as load capacity, speed, and environmental conditions will play vital roles. Many overlook the impact of friction and heat generation. These factors can lead to inefficient energy use.

Moreover, not all energy-efficient bearings are equal. Some may seem reliable but might underperform in real conditions. It's essential to do thorough research and reflect on your choices. Balancing cost with quality can be challenging. Aim for durability and efficiency together.

Understanding Energy Efficiency in Bearings

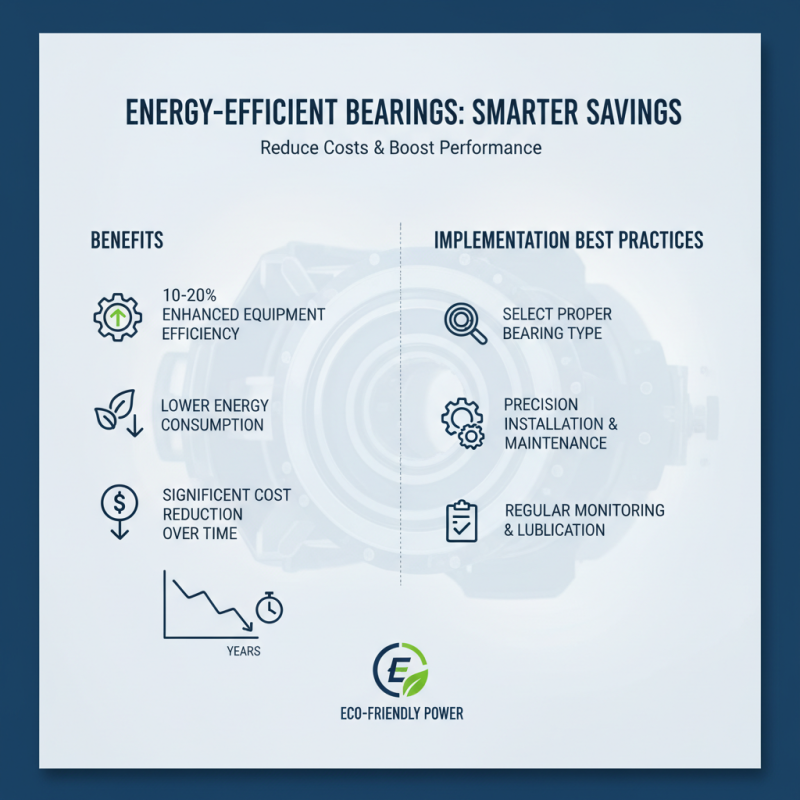

When selecting bearings for your projects, energy efficiency is a key factor. Energy-efficient bearings can significantly reduce operational costs and environmental impact. According to industry reports, up to 20% of total energy consumption in machines can be attributed to bearings. This emphasizes the importance of making informed choices.

Bearings with lower friction coefficients can lead to substantial energy savings. For instance, ceramic hybrid bearings frequently perform better than standard steel bearings. They can reduce friction by as much as 30%, optimizing overall machine performance. Understanding the lubrication needs and the application environment also contributes to energy efficiency. Proper lubrication helps minimize wear, prolongs bearing life, and ultimately enhances energy savings.

Tip: Always analyze the total cost of ownership, not just the initial purchase price. Consider the long-term energy costs and maintenance requirements. Choosing energy-efficient bearings may incur a higher upfront cost but often pays off through reduced energy bills and less frequent replacements.

Tip: Be mindful of operating temperatures. Excessive heat can increase friction and reduce efficiency. Select bearings rated for your specific temperature range to ensure optimal performance. This small detail can make a big difference in energy savings.

Key Factors Influencing Bearing Efficiency

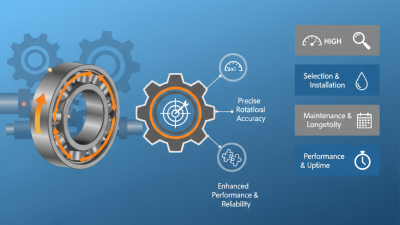

When selecting energy-efficient bearings for projects, several key factors come into play. The design of the bearing significantly affects its efficiency. Deeper grooves and optimized internal geometry can reduce friction. This leads to lower energy consumption. It's essential to analyze what specific design features suit your application.

Material choice cannot be overlooked. Bearings made from lightweight materials often exhibit better efficiency. Yet, finding the right balance between strength and weight can be challenging. Additionally, lubrication type impacts bearing performance. Using low-friction lubricants can enhance efficiency, but sometimes they are not suitable for all conditions.

The operational environment also influences bearing efficiency. Heat, moisture, and contamination can degrade performance over time. Assessing these conditions beforehand is crucial. However, unforeseen variables may arise. Regular evaluation and adjustments to bearing selection can lead to improved energy savings. The process can be complex, but attention to detail pays off.

How to Choose Energy Efficient Bearings for Your Projects? - Key Factors Influencing Bearing Efficiency

| Bearing Type |

Material |

Efficiency Rating |

Load Capacity (kg) |

Operating Temperature (°C) |

| Ball Bearing |

Steel |

High |

150 |

-20 to 120 |

| Roller Bearing |

Chromium Steel |

Medium |

200 |

-30 to 150 |

| Thrust Bearing |

Brass |

Low |

100 |

-10 to 80 |

| Self-Aligning Bearing |

Ceramic |

High |

150 |

-20 to 100 |

| Magnetic Bearing |

Aluminum |

Very High |

50 |

-40 to 200 |

Types of Bearings and Their Energy Consumption

When selecting energy-efficient bearings, understanding their types and energy consumption is crucial. For example, rolling element bearings generally consume less energy than sliding bearings. According to industry reports, rolling bearings can reduce energy loss by up to 30%. This difference in efficiency can have a significant impact on operational costs over time.

Another aspect to consider is the material used in the bearings. Ceramic materials, while more expensive, provide lower friction than traditional steel. They can increase efficiency and extend lifespan. However, the initial investment must be weighed against long-term savings. Data shows that using ceramic bearings can improve energy efficiency by nearly 50%.

Tip: Always analyze load conditions and speed requirements before choosing bearings. These factors directly influence energy efficiency.

Consider also the lubrication methods. Proper lubrication can reduce energy loss in bearings significantly. Many companies report a decrease in energy consumption by 15% when using advanced lubricants. However, not all lubrication practices achieve the same results, prompting businesses to regularly reevaluate their methods.

Evaluating Material Choices for Energy Efficient Bearings

When evaluating material choices for energy-efficient bearings, the material composition is crucial. For instance, steel and plastic have distinct advantages and disadvantages. Steel offers durability but may generate more friction. Conversely, plastic materials are lighter and often reduce noise. The selection of the right material significantly affects energy consumption.

Recent studies suggest that using hybrid materials can lead to a remarkable decrease in energy losses. According to a report by the International Energy Agency, implementing energy-efficient bearings could reduce energy consumption by up to 30% in certain applications. This data highlights the importance of material selection and construction methods. For example, ceramics can withstand higher temperatures and provide lower friction, enhancing their performance in high-speed applications.

Testing different configurations is essential. Not all combinations will yield optimal results. Sometimes materials that seem ideal can fall short in real-world conditions. A thorough analysis of bearing performance and wear can uncover these weaknesses. It’s critical to assess not just technical specifications, but also the operational environment. Reflection on these factors can guide effective choices for your projects.

Energy Efficiency of Various Bearing Materials

This chart compares the energy efficiency of different bearing materials used in engineering projects. The data indicates the friction coefficient and corresponding energy loss during operation.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us