How to Choose High-Precision P4 Grade Bearings for Your Applications?

When selecting bearings for highly demanding applications, High-Precision P4 Grade Bearings stand out as a top choice. These bearings offer exceptional accuracy and reliability, crucial for performance. Industries such as aerospace, robotics, and high-speed machinery often rely on them. Understanding their unique benefits helps users make better decisions.

High-Precision P4 Grade Bearings are designed to operate at high speeds with minimal friction. Their precise dimensions allow for tighter tolerances and smoother rotations. This is essential in environments where every fraction of a millimeter counts. However, choosing the right bearing is not always straightforward. Users may overlook factors such as load capacity or environmental conditions.

It's vital to consider your specific application's requirements. Users must ask themselves: will the bearing perform under different temperatures? Will it handle sudden impacts? Reflecting on these questions can lead to a more informed choice. Even with all their advantages, High-Precision P4 Grade Bearings require proper maintenance and care. Neglecting this aspect can lead to premature failure, which is a point often underestimated.

Understanding P4 Grade Bearings: Definition and Applications

P4 grade bearings are known for their high precision and reliability. They are widely used in various industries. Machine tool spindles, robotics, and medical devices require these bearings. The precision level ensures smooth operation and minimizes wear. This leads to longer service life and better performance.

Choosing P4 bearings involves understanding their specifications. Tolerances are crucial; P4 bearings have tighter ones. This ensures minimal play between the components. Consider load ratings as well. High loads may demand stronger materials. Look for specific application requirements, which can vary significantly. Not all P4 bearings are the same.

Some applications may not truly need P4 grade bearings despite their advantages. Over-specifying can lead to unnecessary costs. It's essential to assess your needs carefully. Consider factors such as speed, load, and environmental conditions. Finding the right balance is key to effective usage. Sometimes, less precision might suffice for certain projects.

How to Choose High-Precision P4 Grade Bearings for Your Applications?

| Dimension |

Specification |

Tolerance |

Load Rating (C) |

Speed Rating (n) |

Application |

| 10 mm x 30 mm x 9 mm |

P4 |

±0.005 mm |

500 N |

20,000 RPM |

Electric Motors |

| 25 mm x 62 mm x 17 mm |

P4 |

±0.005 mm |

920 N |

15,000 RPM |

Machine Tools |

| 30 mm x 55 mm x 13 mm |

P4 |

±0.005 mm |

670 N |

12,000 RPM |

Robotics |

| 20 mm x 42 mm x 12 mm |

P4 |

±0.005 mm |

720 N |

18,000 RPM |

Automotive Components |

Key Specifications of High-Precision P4 Grade Bearings

When choosing high-precision P4 grade bearings, understanding key specifications is vital. P4 bearings are designed for high-speed applications, offering low friction and high rigidity. These bearings must meet strict dimensional tolerances, typically within a range of 0.5 to 1.0 microns. A report from the American Bearing Manufacturers Association states that bearing precision affects overall system performance.

The load capacity of P4 grade bearings plays a crucial role in their application. Standard dynamic load ratings can vary between 15,000 to 30,000 newtons. This capability allows for efficient operation in machine tools and robotics. A well-calibrated bearing not only increases lifespan but also enhances precision. However, inadequate lubrication can detrimentally impact these essential specifications. Regular monitoring of lubrication levels is a necessity, not an option.

Another important factor is the material composition. Typically, P4 bearings use high carbon chromium steel or ceramic materials. These choices provide improved hardness and wear resistance. Yet, inconsistencies in material quality can lead to premature failure. It’s essential to source bearings from reputable suppliers who maintain strict quality controls.

Factors Influencing the Selection of P4 Grade Bearings

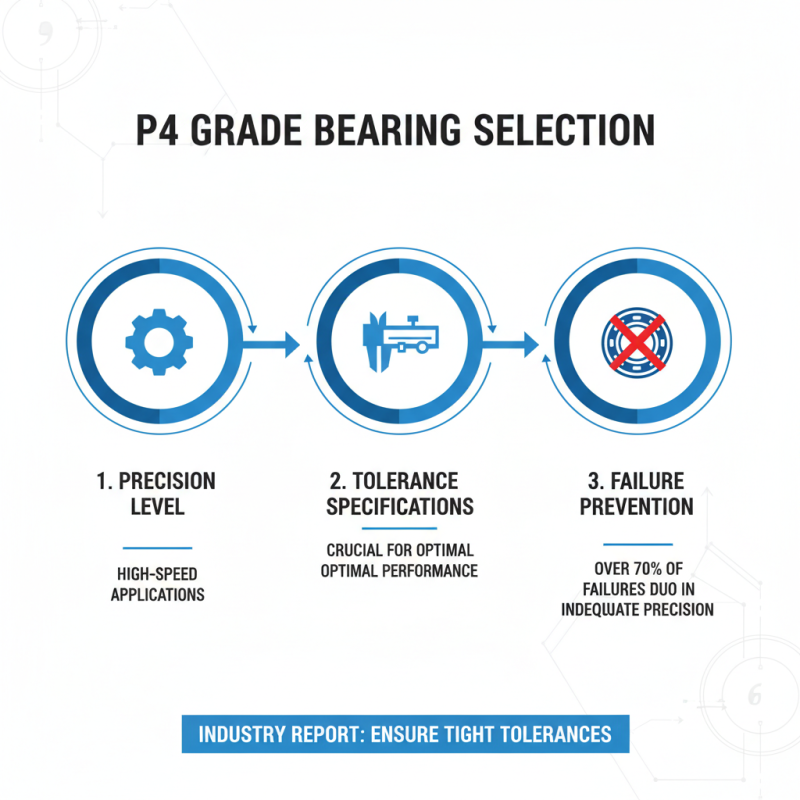

When selecting P4 grade bearings, several critical factors come into play. The precision level is one of the primary influences. P4 bearings are designed for high-speed applications, yet tolerance levels are crucial. According to a recent industry report, over 70% of bearing failures stem from inadequate precision. Therefore, assessing tolerance specifications ensures optimal performance.

Another key factor is the operating environment. Vibration, temperature, and lubrication conditions impact bearing choices significantly. For instance, operating temperatures above 120°C can alter properties and lead to premature wear. Metrics show that bearing lifespan drops by 50% under extreme conditions. Choosing the right materials, such as ceramic or high-alloy steel, can mitigate these risks.

Finally, the application load affects bearing selection. Static and dynamic loads must be evaluated meticulously. Research indicates that bearings can fail under overload conditions, even if they’re rated for high capacities. Therefore, precise load calculations are necessary for longevity. Understanding these factors is essential for achieving high performance and reliability in your applications.

Comparative Analysis: P4 Grade vs. Other Bearing Grades

When selecting high-precision P4 grade bearings, understanding the differences with other grades is crucial. P4 grade bearings are renowned for their tight tolerances and high precision. A study indicates that P4 bearings maintain a dimensional accuracy of up to 5 micrometers. This feature is essential in applications like aerospace and medical equipment, where precision is non-negotiable.

In contrast, P5 and P6 grade bearings offer lower precision. P5 bearings have tolerances that range between 5 to 10 micrometers, which may suffice for less demanding applications. However, if machinery experiences vibrations or fluctuating loads, P5 bearings may wear out faster. A report from the International Bearing Association highlights that using P4 instead of P5 can extend lifespan by up to 30%.

It’s essential to reflect on your specific needs. While P4 bearings offer superior performance, they come at a higher cost. For some applications, the extra investment may not deliver proportional benefits. Balancing precision requirements with budget constraints can be challenging, yet it’s necessary for making informed decisions.

Comparison of Bearing Accuracy Grades

This chart illustrates the accuracy levels of different bearing grades. P4 grade bearings provide a precision of up to 5 micrometers, making them the preferred choice for high-precision applications compared to lower-grade bearings.

Maintenance Practices to Enhance P4 Grade Bearings' Lifespan

Proper maintenance can significantly extend the lifespan of P4 grade bearings. According to a recent industry report, bearings with high precision can operate effectively for over 20,000 hours when well-maintained. Regularly checking lubrication levels is crucial. Insufficient lubrication leads to increased friction and wear. This can shorten bearing life dramatically. Aim for a clean, dry environment. Dust and contaminants can compromise performance. A recent study indicated that particles as small as 10 microns can cause severe damage.

Vibration analysis is another valuable practice. It helps in early detection of issues before they escalate. A survey by a leading engineering organization found that 30% of bearing failures result from undetected vibrations. Regular monitoring can prevent costly shutdowns. Thermographic inspections can also be beneficial. They identify hot spots indicating excessive friction. Maintaining optimal operating temperatures enhances reliability. Researchers highlight that temperature variations above the ideal range can reduce lifespan by up to 30%.

Be proactive about symptoms like noise or abnormal movement. Ignoring these signs can lead to failure. An engineer’s guide stresses the importance of addressing early warnings. Failing to do so can result in unexpected downtime. In a competitive market, ensuring the longevity of your P4 bearings is essential for operational efficiency. Prioritize consistent maintenance routines to realize the full potential of your high-precision bearings.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us