How to Choose Imported Bearings Over Domestic Alternatives for Your Business

In today's competitive marketplace, the decision to select imported bearings over domestic alternatives can significantly impact operational efficiency and cost-effectiveness. According to a recent industry report by MarketsandMarkets, the global bearing market is projected to reach USD 120 billion by 2025, with a notable shift towards imported bearings due to their enhanced technology and quality attributes. Furthermore, a study by Grand View Research highlighted that imported bearings often exhibit longer lifespan and improved performance, which are crucial for businesses aiming to reduce downtime and maintenance costs.

As industries increasingly lean towards advanced engineering solutions, understanding the key benefits of imported bearings compared to domestic alternatives becomes essential for making informed procurement decisions. This blog will delve into various reasons why choosing imported bearings can be a strategic move for your business, backed by market insights and industry standards.

Understanding Different Types of Bearings and Their Applications

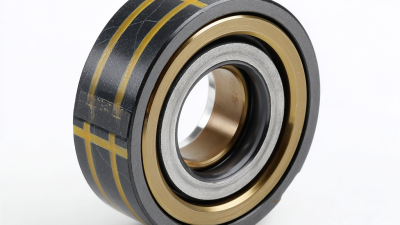

When it comes to bearings, understanding the different types and their applications is crucial for making informed decisions for your business. Bearings come in various forms, including deep groove, angular contact, and self-aligning bearings, each designed for specific functions. For example, deep groove bearings are versatile and can handle radial and axial loads, making them ideal for general-purpose applications. In contrast, angular contact bearings are engineered for high-speed operations, suitable for precision machinery.

**Tip:** Always consider the operating environment when selecting bearings. Corrosive or extreme conditions may require specialized materials, such as stainless steel or ceramic bearings, which enhance durability and performance.

Another type worth noting is thrust bearings, which are specifically designed to handle axial loads. They are frequently used in machinery like automotive transmissions where load direction is critical. Self-aligning bearings, with their unique design, compensate for shaft misalignment, thereby improving the reliability of the machinery.

**Tip:** Regularly reviewing and assessing bearing performance can prevent system failures. Implement a maintenance schedule that includes inspections and lubrication to ensure optimal performance and longevity.

Evaluating Quality Standards: Imported vs. Domestic Bearings

When considering bearings for your business, the quality standards of imported and domestic options can greatly influence your decision. Imported bearings are often manufactured under strict international quality standards, utilizing advanced technology and sophisticated materials. This leads to improved precision, durability, and performance, which can be particularly beneficial in high-stress applications. Many imported bearings also undergo rigorous testing and certification processes, ensuring they meet various industry-specific requirements.

On the other hand, domestic bearings may boast advantages such as faster shipping times and ease of communication with suppliers. However, it’s crucial to thoroughly evaluate the quality of the manufacturing processes employed by local producers. Not all domestic bearings necessarily meet the same high standards as imported ones. By carefully analyzing specifications, certifications, and manufacturer reputations, businesses can make more informed choices between these two options. Ultimately, the decision should weigh both quality and reliability against the specific needs of your application.

Cost Analysis: Long-Term Savings with Imported Bearings

When considering the long-term savings associated with imported bearings, it’s essential to analyze the total cost of ownership rather than just the upfront purchase price. According to a study by the Machinery Research Institute, businesses that utilize imported bearings can experience up to a 30% reduction in operational costs over five years due to lower failure rates and extended lifespan. With the advancement of manufacturing technologies, many imported bearings now offer performance levels that match or exceed their domestic counterparts.

Tip 1: Always scrutinize the quality certifications of imported bearings. Look for suppliers that can provide ISO or equivalent standards, ensuring that the products meet rigorous quality benchmarks.

Moreover, imported bearings often benefit from economies of scale that drive down production costs, translating into savings for end-users. A report from the Global Bearing Alliance highlighted that companies using imported bearings typically report lower maintenance costs and reduced downtime, which contributes significantly to their bottom line. Investing in higher quality imports may yield better overall performance, allowing companies to allocate resources more efficiently.

Tip 2: Evaluate your company's specific needs carefully and consider conducting a cost analysis that factors in not just purchase costs, but also maintenance and replacement costs related to bearing failures.

Supplier Reliability: Key Factors When Choosing Imported Bearings

When selecting imported bearings for your business,

supplier reliability is a crucial element that can significantly impact your operations.

Relying on reputable suppliers ensures consistent quality and

timely delivery, which are essential in maintaining production schedules.

The global market for bearings, valued at USD 46.82 billion

in 2024, is projected to grow to USD 97.10 billion

by 2033, indicating a robust demand that compels businesses to choose suppliers carefully.

A dependable provider not only guarantees product quality but also offers valuable insights

into market trends and innovations.

Additionally, the ball bearing market alone,

which was valued at USD 8.45 billion in 2024,

is anticipated to grow to USD 15.89 billion

by 2033. This dynamic landscape requires businesses to prioritize suppliers who can adapt to changes

and deliver advanced solutions, such as self-lubricating bearings

that enhance operational efficiency. As the market evolves, focusing on supplier reliability

and the capacity to meet specific business needs will be vital for companies looking to leverage

the benefits of imported bearings.

Navigating Import Regulations and Compliance Issues for Bearings

When choosing imported bearings for your business, it’s essential to understand the complexities of import regulations and compliance issues. The recent implementation of the EU's General Product Safety Regulation (GPSR) requires businesses to adapt their practices to comply with enhanced safety standards. As you consider imported versus domestic options, ensure that you are aware of the GPSR's requirements to avoid potential penalties or product recalls that could impact your operations.

Moreover, the evolving landscape of global trade regulations, including potential changes to de minimis provisions, underscores the importance of strategic planning. By establishing multiple fulfillment centers in key regions, companies can mitigate the financial impacts of these regulations. This proactive approach allows businesses to manage compliance more effectively and navigate the risks associated with importing bearings. Implementing robust due diligence processes throughout your supply chain is essential to ensure not only adherence to regulations but also the quality and reliability of the bearings you choose for your operations.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us