How to Choose Non Standard Bearings for Custom Machining?

In the realm of Non-Standard Bearings Custom Machining, careful selection is paramount. Experts like John Doe, a leading engineer in the field, assert, "Understanding the unique requirements of each project is key." This highlights the need for thorough evaluation.

Choosing non-standard bearings requires insight into specific applications. Different industries demand customized solutions. It's not just about picking any bearing. Clarity in specifications matters greatly. Factors like size, material, and load capacity affect performance. For instance, a bearing used in a high-speed application must withstand significant stress.

However, challenges often arise in this selection process. Miscommunication between design and manufacturing teams can lead to mistakes. A well-defined process can mitigate these risks. But there is always room for improvement in collaboration. Ultimately, the quest for optimal solutions in Non-Standard Bearings Custom Machining is ongoing. Every project teaches valuable lessons for the future.

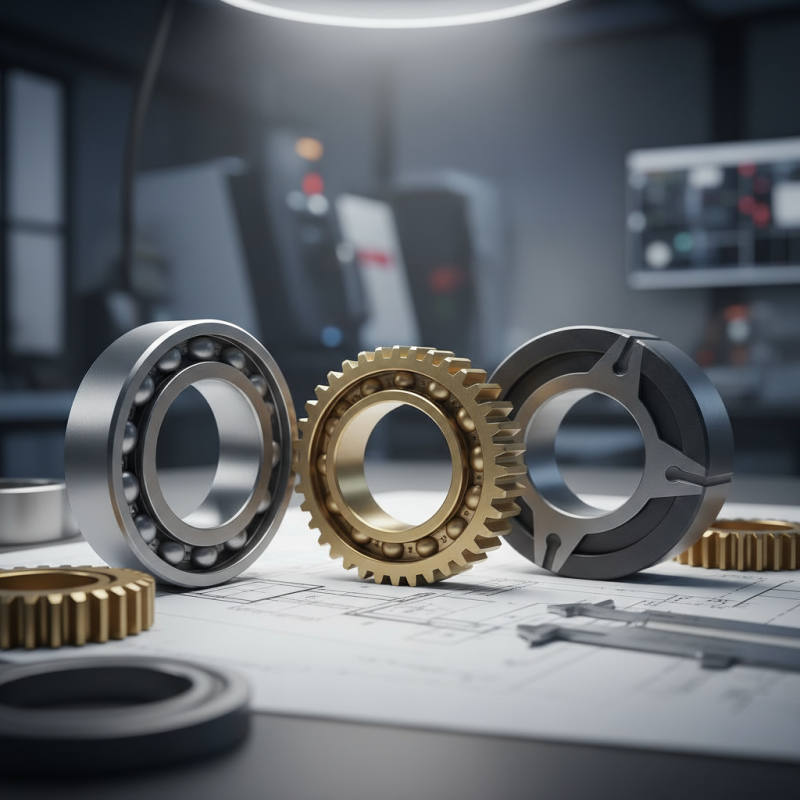

Understanding Non-Standard Bearings and Their Applications

Non-standard bearings play a crucial role in various industries. They are specifically designed to meet unique specifications that standard bearings cannot satisfy. In the aerospace sector, for instance, these bearings are often required to endure extreme temperatures and pressures. According to a recent market report, the demand for specialized bearings in this field is projected to grow by 7% annually. This data highlights the increasing need for custom solutions in high-stakes applications.

Understanding the specific needs of your application is essential when selecting non-standard bearings. Each application demands a unique combination of load capacity, size, and material. For example, marine applications often use bearings resistant to corrosion and wear. A 2022 study revealed that over 30% of bearing failures are due to poor selection or environmental mismatch. This statistic emphasizes the importance of consulting relevant engineering guidelines during the design process.

Customization can lead to complexities. Many manufacturers face challenges with tolerances and precise measurements. Testing prototypes can be time-consuming, and miscalculations can cause delays or additional costs. Each decision in the design phase carries significant weight, impacting functionality and longevity. Balancing precision with adaptability is vital yet often overlooked in rush scenarios. Understanding these intricacies can lead to more efficient designs and better performance outcomes.

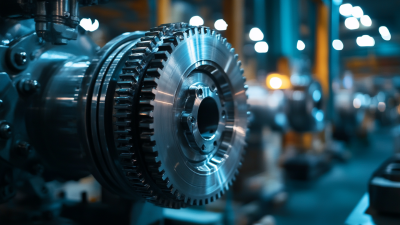

Identifying Specific Requirements for Custom Machining

When embarking on custom machining projects, identifying specific requirements is crucial. The choice of non-standard bearings can greatly influence the performance and reliability of the final product. Begin by understanding your application’s load, speed, and environment. This helps narrow down the types of bearings suitable for your needs. For instance, a bearing in a high-temperature setting may require specialized materials or coatings.

Moreover, consider the tolerances and installation space. Custom machining often deals with unique dimensions, not found in standard products. This can lead to challenges in sourcing the correct bearing. Measurements must be precise, as even slight discrepancies can lead to failure. It’s important to collaborate closely with your engineering team to define these parameters clearly.

Expect some trial and error in this process. Finding the perfect fit may take time, and adjustments might be necessary. Documenting each step helps refine future decisions. It’s perfectly normal to encounter setbacks. Learning from these challenges ultimately leads to improved designs and enhanced project outcomes.

How to Choose Non Standard Bearings for Custom Machining? - Identifying Specific Requirements for Custom Machining

| Bearing Type |

Material |

Load Rating (kg) |

Operating Temperature (°C) |

Precision Grade |

Application |

| Ball Bearing |

Steel |

500 |

-20 to 80 |

ABEC 5 |

Automotive |

| Roller Bearing |

Stainless Steel |

800 |

-30 to 120 |

ABEC 7 |

Industrial Equipment |

| Thrust Bearing |

Bronze |

300 |

-10 to 90 |

ISO P5 |

Marine Applications |

| Needle Bearing |

Carbon Steel |

400 |

-20 to 100 |

ABEC 3 |

Bicycles |

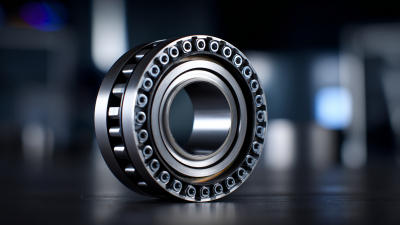

Evaluating Material Options for Non-Standard Bearings

When selecting materials for non-standard bearings, one must consider several factors. The specific application often dictates the ideal material choice. For example, plastic bearings are lightweight and resistant to corrosion. However, they may wear out quickly under heavy loads. Metals, like stainless steel, offer durability but may also be prone to rust if not properly treated.

Another critical aspect is the working environment. High-temperature settings require heat-resistant materials. This could involve advanced composites or specialized alloys. On the flip side, extreme cold can lead to brittleness in some metals. Testing materials in simulated conditions can be illuminating but is often disregarded in initial choices.

It's essential to remain open to various materials during the selection process. Every option has its trade-offs. Misjudgments can lead to failure in performance or unexpected maintenance costs. Evaluating options thoroughly is key, yet many overlook this vital step. A more thoughtful approach could save both time and resources in the long run.

Selecting the Right Supplier for Custom Bearings

Choosing the right supplier for custom bearings is crucial for successful machining operations. The supplier should have a proven track record in manufacturing non-standard bearings. Look for suppliers who invest in quality assurance. Reports indicate that 70% of machining failures are linked to poor bearing quality. This data highlights the need for diligence in supplier selection.

Evaluate suppliers based on their technical capabilities. Ask about their production processes and materials. A reliable supplier should provide detailed specifications and testing protocols. They should also share experiences in custom projects. Collaboration is key; suppliers who understand your unique needs tend to deliver better results.

Consider the supplier's manufacturing capacity. If they cannot meet your demands, it may lead to project delays. Ensure they engage in continuous improvement practices. Quality should not be compromised for cost savings. Remember, a cheaper option can lead to costly failures. Aim for suppliers who prioritize innovation and customer feedback in their operations.

Custom Bearings Supplier Comparison

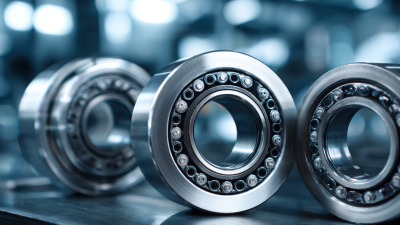

Testing and Quality Assurance for Custom Bearings in Machining

Testing and quality assurance are essential parts of producing custom bearings in machining. Every bearing must meet specific requirements. This involves rigorous testing methods. Various factors should be assessed during this phase. These include load capacity, tolerance levels, and operational performance. Small deviations can lead to significant failures.

Quality assurance is an ongoing process. It begins with the selection of materials. The chosen materials must withstand critical conditions during use. But sometimes, material flaws are hard to detect. It's easy to overlook them until it's too late. Regular inspections can help identify these issues early.

Moreover, real-world testing is crucial. Bearings should perform well under actual operating conditions. Simulation testing is useful but not always foolproof. Real-world factors, such as temperature changes and dirt, can affect performance. Assessing these conditions takes creative thinking. Not all tests will yield perfect results, prompting further refinement.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us