Why Choosing the Right Tapered Roller Bearings Supplier is Crucial for Your Machinery Performance

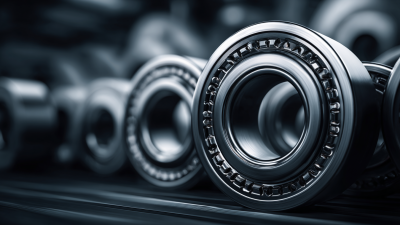

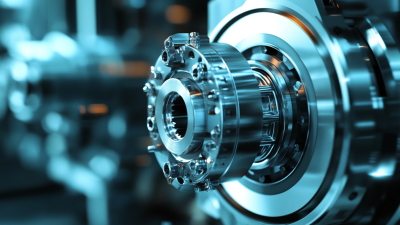

When it comes to ensuring optimal machinery performance, selecting the right Tapered Roller Bearings Supplier is a decision that can significantly impact operational efficiency and longevity. Tapered roller bearings play a vital role in various industrial applications, supporting heavy loads and allowing for smooth rotational movements. Therefore, the supplier you choose must not only provide high-quality products but also possess a robust understanding of your specific needs and the operational demands of your machinery.

In a market teeming with potential suppliers, distinguishing the top performers is crucial. The "2025 Top 10" list aims to highlight the most reputable Tapered Roller Bearings Suppliers, emphasizing their commitment to quality, innovation, and customer service. By carefully considering these suppliers, businesses can mitigate risks of failure, reduce maintenance costs, and ultimately enhance productivity. This guide will delve into the critical factors that make choosing the right supplier paramount in achieving machinery excellence.

The Impact of Tapered Roller Bearings on Machinery Efficiency and Longevity

The efficiency and longevity of machinery are significantly influenced by the quality of tapered roller bearings. With the global bearings market projected to grow from USD 50.16 billion in 2025 to USD 97.10 billion by 2034, it is clear that the demand for high-performance components is on the rise. Tapered roller bearings, known for their ability to handle both radial and axial loads, play a critical role in enhancing the operational efficiency of various machinery. As industries worldwide focus on improving productivity, the selection of the right bearings supplier becomes vital.

Recent reports highlight that the roller bearings market, valued at USD 15.7 billion in 2024, is expected to expand at a compound annual growth rate (CAGR) of 4.7% from 2025 to 2034. This growth is largely driven by advancements in bearing technology and the increasing need for more reliable and sustainable solutions in industrial applications. As companies strive for innovation, the right supplier can provide not only high-quality products but also valuable insights into optimizing machinery performance, thereby contributing to the overall efficiency and longevity of operations.

Key Performance Metrics in Selecting Tapered Roller Bearings Suppliers

When selecting a supplier for tapered roller bearings, understanding key performance metrics is vital to ensure optimal machinery performance. One of the foremost metrics is the bearing's load capacity, which is critical for the longevity and reliability of machinery. According to a study by the American Bearing Manufacturers Association, bearings designed for high-load applications can improve uptime by 15-20%. This underscores the importance of not only choosing a supplier that offers high-quality products but also one that will meet the specific load requirements of your applications.

Additionally, consider the supplier’s delivery and lead times. A report from Frost & Sullivan indicates that delays in bearing supply can halt manufacturing processes, resulting in an average loss of $100,000 per hour for large operations. Thus, a supplier's ability to provide timely delivery should be a cornerstone of your selection criteria.

Tips: Look for suppliers with a proven track record and strong customer reviews. Always request detailed specifications and performance testing data to verify the quality of the bearings. Prioritize suppliers who offer robust support services, ensuring you have assistance for installation and maintenance.

Industry Standards and Certifications for Quality Assurance in Bearing Supply

When selecting a supplier for tapered roller bearings, understanding the industry standards and certifications is essential for ensuring quality assurance. Regulatory bodies often set guidelines that suppliers must adhere to, which helps in minimizing defects and maintaining high performance levels in machinery. Look for certifications such as ISO 9001, which indicates a strong commitment to quality management systems.

Tips: When evaluating potential suppliers, request documentation that verifies their certifications. Additionally, consider suppliers who engage in continuous improvement programs to enhance product quality and reliability.

Choosing a supplier who complies with recognized standards not only assures you of the product's quality but also enhances the overall performance of your machinery. Components that meet stringent criteria are less likely to fail, ultimately saving you time and costs associated with maintenance and replacements.

Tips: Regularly review suppliers' compliance with industry standards and certifications to ensure they remain committed to quality. This proactive approach can significantly impact your machinery's efficiency and longevity.

Cost-Benefit Analysis: Investing in High-Quality Tapered Roller Bearings

Choosing the right supplier for tapered roller bearings is not just a matter of cost but a strategic investment that significantly impacts machinery performance. As the global bearings market is projected to grow from USD 50.16 billion in 2025 to an impressive USD 97.10 billion by 2035, the demand for high-quality components has never been more evident. With the roller bearings market alone expected to surpass USD 15.7 billion by 2024, industries are recognizing that investing in superior quality can result in enhanced operational efficiency and reduced long-term costs.

Conducting a cost-benefit analysis is essential when selecting a tapered roller bearings supplier. While the initial procurement of premium bearings may be higher, the long-term savings associated with decreased maintenance costs and longer lifecycle can justify the investment. For example, the large-scale bearing market is anticipated to grow at a CAGR of 6.1%, indicating a robust market trend towards reliable and durable products. Hence, investing in high-quality tapered roller bearings not only guarantees better performance but also positions companies to leverage future growth in an expanding market.

Why Choosing the Right Tapered Roller Bearings Supplier is Crucial for Your Machinery Performance - Cost-Benefit Analysis: Investing in High-Quality Tapered Roller Bearings

| Supplier Evaluation Criteria |

Importance Level (1-5) |

Cost of High-Quality Bearings (per unit) |

Expected Lifespan (hours) |

Downtime Cost (per hour) |

Total Cost (Lifetime) |

| Quality Assurance |

5 |

$50 |

10000 |

$200 |

$700,000 |

| Supplier Reputation |

4 |

$55 |

9500 |

$180 |

$681,000 |

| Technical Support |

3 |

$48 |

9200 |

$210 |

$774,000 |

| Delivery Time |

5 |

$52 |

11000 |

$220 |

$560,000 |

| Warranty and After-Sales Support |

4 |

$45 |

9800 |

$190 |

$628,000 |

Case Studies: Success Stories from Leading Machinery Manufacturers

Choosing the right supplier for tapered roller bearings is essential for ensuring optimal machinery performance, particularly in a landscape marked by rapid advancements and digital transformations. Case studies from leading machinery manufacturers illustrate the significant impact that quality bearings and reliable suppliers can have on operational efficiency. For instance, companies that prioritized partnerships with skilled bearing manufacturers began to see marked improvements in machine uptime and productivity, validating the notion that a well-informed selection can spark success.

Recent trends highlight the necessity of innovation and digital integration in manufacturing. A notable example includes a prominent machinery manufacturer that embraced a digital transformation strategy, leveraging automated solutions and advanced manufacturing processes to streamline operations. This not only enhanced productivity but also underscored the importance of precise component sourcing, such as reliable tapered roller bearings, in maintaining the integrity and performance of their machinery. These success stories serve as a testament to the vital role that the right supplier plays in enabling manufacturers to navigate the complexities of the modern industrial environment.

Impact of Tapered Roller Bearings Supplier Quality on Machinery Performance

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us