How to Choose Thrust Ball Bearings for Custom Manufacturing?

Choosing the right thrust ball bearings for custom manufacturing can be challenging. This decision impacts the performance and reliability of your machinery. Understanding the specifics of thrust ball bearings custom manufacturing is essential.

Key factors include load capacity and material selection. Thrust ball bearings must handle axial loads efficiently. The choice of materials can affect durability and weight. Manufacturers often overlook these details.

Consider the operating environment for the bearings. Factors like temperature, moisture, and contamination can influence performance. Inadequate selection may lead to failures. Therefore, careful evaluation is necessary. Understanding your requirements can aid in making better choices.

Understanding Thrust Ball Bearings and Their Applications

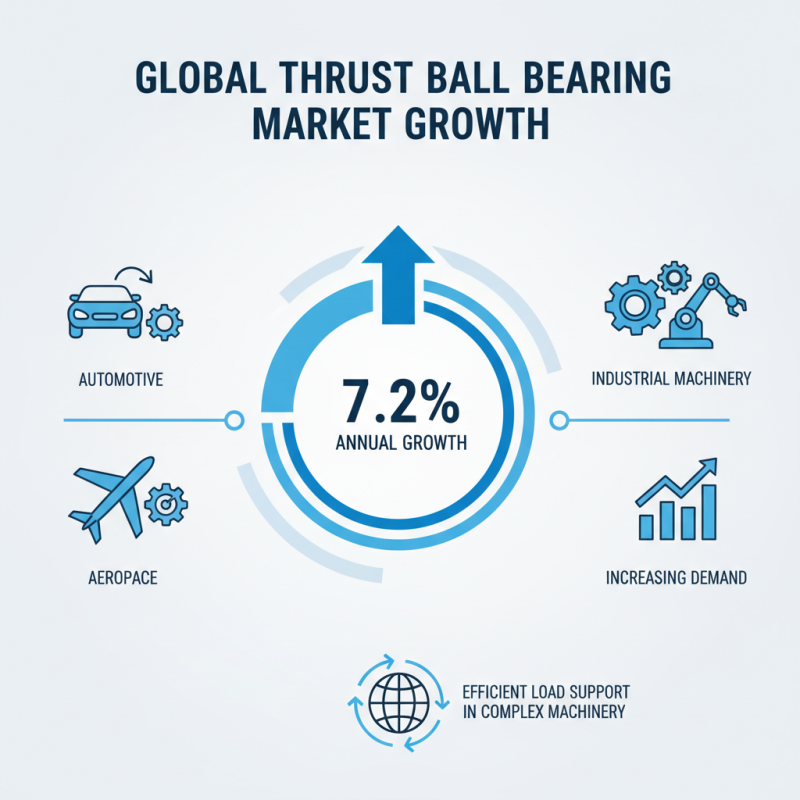

Thrust ball bearings are essential components in various industries. They are designed to support axial loads and allow rotational movement. Typically, these bearings are used in applications like automotive, aerospace, and industrial machinery. According to a recent industry report, the global thrust ball bearing market is projected to grow by 7.2% annually. This growth underscores the increasing demand for efficient load support in complex machinery.

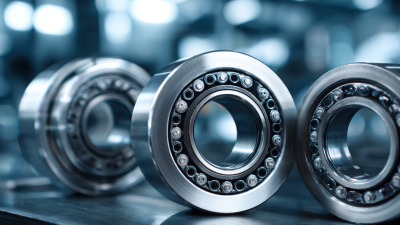

In custom manufacturing, understanding the specific application of thrust ball bearings is crucial. For example, in high-speed applications, low friction and precision are vital. If a bearing fails to meet these requirements, it can lead to significant downtimes. While there are many types available, not every thrust ball bearing is suited for all conditions. Selecting the right material and design is necessary. In some cases, using standard bearings may not yield optimal performance.

Several factors can influence the choice of thrust ball bearings. Load capacity, speed ratings, and environmental conditions are key parameters. Ignoring these can result in inefficient operations. For instance, a bearing with inadequate load capacity can wear out quickly. This creates a cycle of replacements that could have been avoided. Manufacturers must conduct thorough assessments to choose the right bearing solution.

Key Factors to Consider When Selecting Thrust Ball Bearings

When selecting thrust ball bearings for custom manufacturing, several key factors play a crucial role. Load capacity is one of the primary considerations. Thrust ball bearings are designed to handle axial loads. A report from the Bearing Manufacturers Association suggests that engineers should assess the maximum load that the application may impose. Overestimating can lead to premature failure.

Material choice is another important factor. Stainless steel is commonly used for its corrosion resistance, while chrome steel offers higher load-bearing capabilities. According to industry studies, the life expectancy of bearings made from these materials can differ significantly. Regularly, a well-selected material can enhance performance and reliability.

**Tips:** Consider the operational environment. Exposure to extreme temperatures or contaminants can dramatically affect the bearing's life. Make sure to review application conditions. Another tip is to verify lubrication requirements. Insufficient lubrication can result in increased wear.

Overall, consult with engineers who specialize in bearings to gain insights tailored to specific requirements. Choosing the right thrust ball bearing is not a one-size-fits-all approach. A thorough understanding of the application will lead to better performance.

Materials and Design Options for Custom Thrust Ball Bearings

When selecting materials for custom thrust ball bearings, consider the application requirements carefully. Common materials include stainless steel, chrome steel, and ceramic. Each material has unique properties. For instance, stainless steel offers good corrosion resistance, while ceramics can provide lower weight and higher stiffness. According to industry reports, over 30% of failure issues in bearings can be traced back to material selection.

Design options are equally important. Thrust ball bearings come in various configurations. You can choose from single direction or double direction bearings. Make sure to assess load capacity and speed requirements. According to a recent study, miscalculations in load ratings lead to decreased bearing life. Remember, a well-designed bearing reduces friction and improves efficiency.

Tips: Always verify compatibility with your application environment. Conduct regular maintenance checks to avoid premature failure. Ensure proper lubrication to minimize wear. Small details matter in ensuring optimal performance.

Thrust Ball Bearings Material Comparison

This bar chart displays the comparison of the strength of different materials used for thrust ball bearings. Understanding the strength characteristics of each material is crucial for selecting the appropriate option for custom manufacturing applications.

Performance Metrics and Specifications for Thrust Ball Bearings

Choosing the right thrust ball bearings for custom manufacturing requires careful consideration of performance metrics and specifications. Factors such as load capacity, speed limits, and materials are crucial. According to the latest industry reports, bearings often support axial loads of several hundred to thousands of Newtons, depending on size. Each application may demand unique specifications tailored to its operational context.

When examining performance metrics, load ratings stand out. The dynamic load rating indicates how much load a bearing can handle while in motion. Static load ratings reveal capacity under stationary conditions. Reports show that even slight deviations in load specifications can lead to premature failure. Thus, it's vital to choose according to the specific needs of your application.

Tip: Always assess the operating environment. Extreme temperatures or contaminants impact bearing life.

Material selection also plays a pivotal role. Steel offers strength, but ceramic materials can reduce weight and improve corrosion resistance. However, they might not perform well under high stress, leading to potential weaknesses. Regular reviews of application requirements can save time and resources.

Tip: Consider a backup plan. Not all bearings will meet your expectations. Testing prototypes can identify flaws early.

Common Pitfalls to Avoid in Thrust Ball Bearing Selection

Choosing the right thrust ball bearings can be challenging. One common pitfall is overlooking load ratings. According to a recent report, improper load rating selection can reduce bearing life by up to 25%. It is crucial to match the bearing to the actual load conditions in your application.

Another issue is neglecting installation quality. Faulty installation techniques can lead to misalignment. This, in turn, can cause premature wear and failure. A surprising statistic shows that about 30% of bearing failures result from incorrect installation. Attention to detail is vital here.

Environmental conditions are often ignored in the selection process. Factors like temperature and humidity play significant roles in performance. Failing to consider these can lead to poor bearing performance. A study indicates that bearings used in inappropriate environments can lose up to 40% efficiency. Understanding the operating conditions is essential for longevity.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us