Unlocking Efficiency with Custom Linear Motion Bearings for Large Scale Purchases

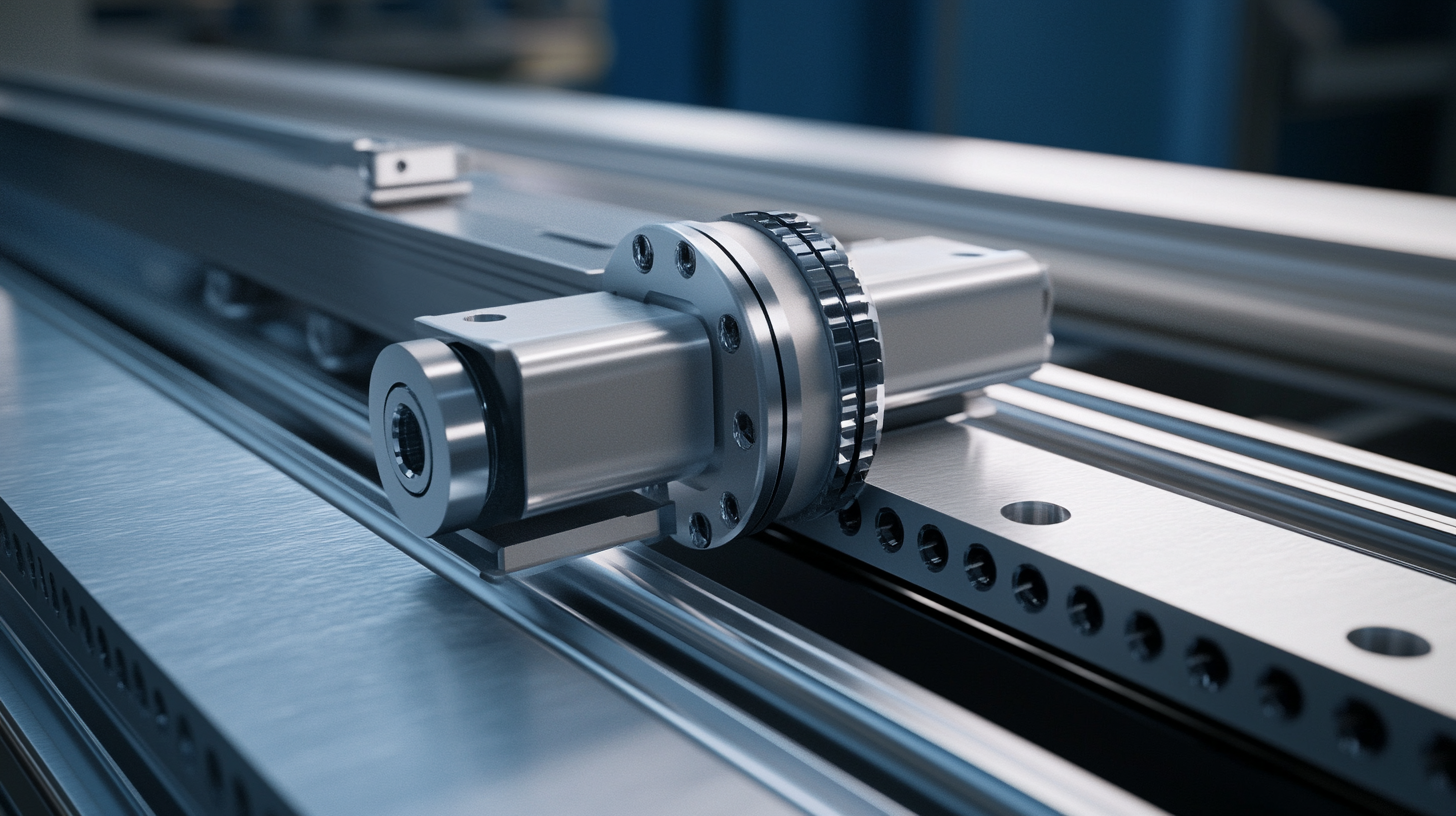

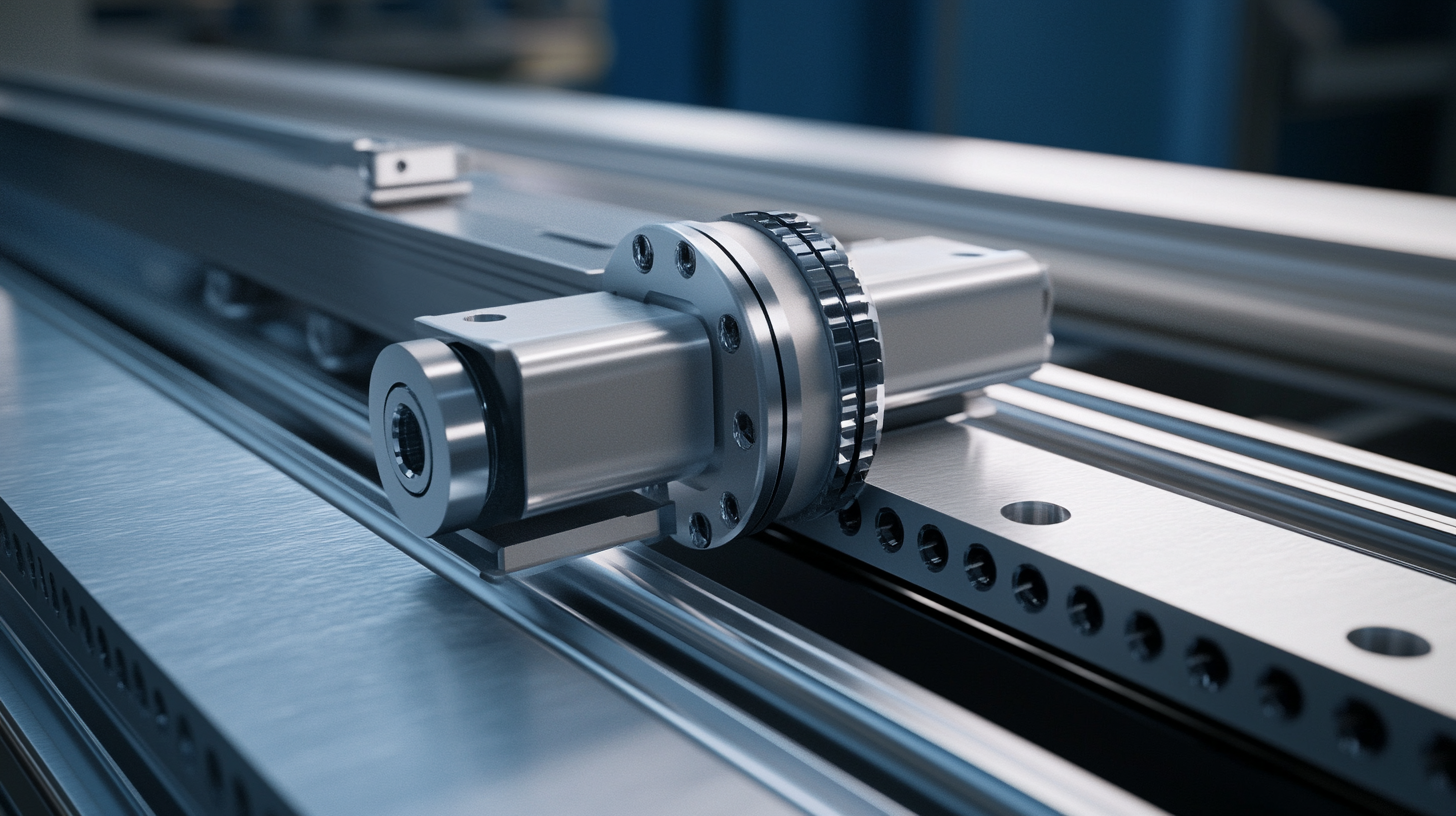

In today’s competitive manufacturing landscape, efficiency is paramount, and companies are continually seeking ways to optimize their production processes. One often overlooked yet critical component in achieving this efficiency is the use of custom linear motion bearings. As businesses grow, the demand for reliable and high-performance components increases, leading to the necessity for linear motion bearings bulk order opportunities. By tailoring these bearings to meet specific operational needs, companies can significantly enhance their equipment's performance, reduce downtime, and ultimately improve productivity. This blog will explore the benefits of investing in custom linear motion bearings, particularly for organizations looking to make substantial bulk purchases. We will discuss how these custom solutions not only meet distinct requirements but also contribute to cost savings, making them an invaluable asset for large-scale operations.

Benefits of Custom Linear Motion Bearings for Bulk Applications

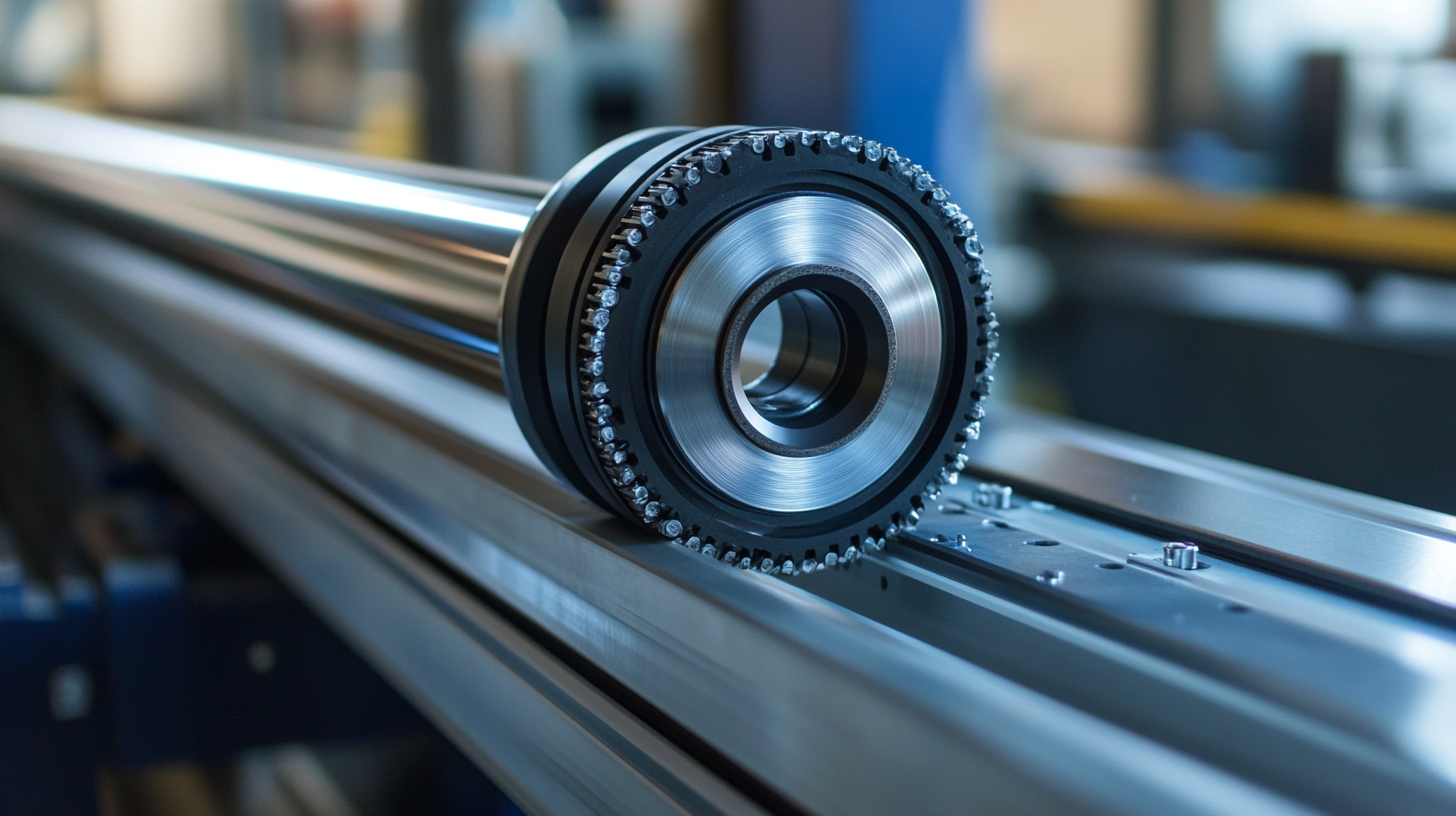

In the world of industrial applications, custom linear motion bearings have become a crucial component for companies engaged in large-scale purchases. These bearings are specifically designed to meet the unique requirements of bulk applications, offering unparalleled efficiency and reliability. By opting for custom designs, businesses can address specific load capacities, environmental conditions, and space constraints that standard solutions often fail to accommodate.

One of the key benefits of using custom linear motion bearings in bulk is the enhanced performance tailored to particular processes. Manufacturers can optimize the bearing's materials and dimensions to fit their exact needs, which leads to less friction, higher precision, and increased durability. Additionally, custom solutions can reduce downtime by ensuring that components are perfectly matched to the operational demands, minimizing wear and tear over time.

Furthermore, integrating custom linear motion bearings into large-scale operations can yield significant cost savings in the long run. While the upfront investment may be higher compared to off-the-shelf options, the resultant efficiency improvements and decreased maintenance needs often outweigh these initial costs. Businesses benefit from increased production rates and reduced operational interruptions, ultimately contributing to their bottom line while maintaining a competitive edge in their respective markets.

Unlocking Efficiency with Custom Linear Motion Bearings for Large Scale Purchases

| Feature |

Description |

Benefits |

Application Areas |

| Customization |

Tailored specifications to meet specific operational needs. |

Enhanced performance and reliability. |

Manufacturing, Robotics |

| Material Selection |

Utilization of high-quality materials for durability. |

Longer lifespan and lower maintenance costs. |

Aerospace, Automotive |

| Scalability |

Designed to handle increased loads and volumes smoothly. |

Supports business growth and adaptability. |

Industrial Automation, Packaging |

| Cost Efficiency |

Bulk purchasing options to lower overall costs. |

Increased profitability and lower unit costs. |

Construction, Mining |

| Performance Optimization |

Engineered for superior motion accuracy and speed. |

Improved operational efficiency. |

Textile, Electronics |

Key Factors to Consider When Sourcing Linear Motion Bearings

When sourcing linear motion bearings for large-scale purchases, understanding the market dynamics and specific requirements is crucial for maximizing efficiency. The global linear motion bearing market, valued at approximately USD 9.13 billion in 2023, is projected to grow at a compound annual growth rate (CAGR) of 5.7% through 2030. This significant growth presents an opportunity for businesses to optimize their supply chains and improve operational efficiency by investing in custom solutions that align with specific application needs.

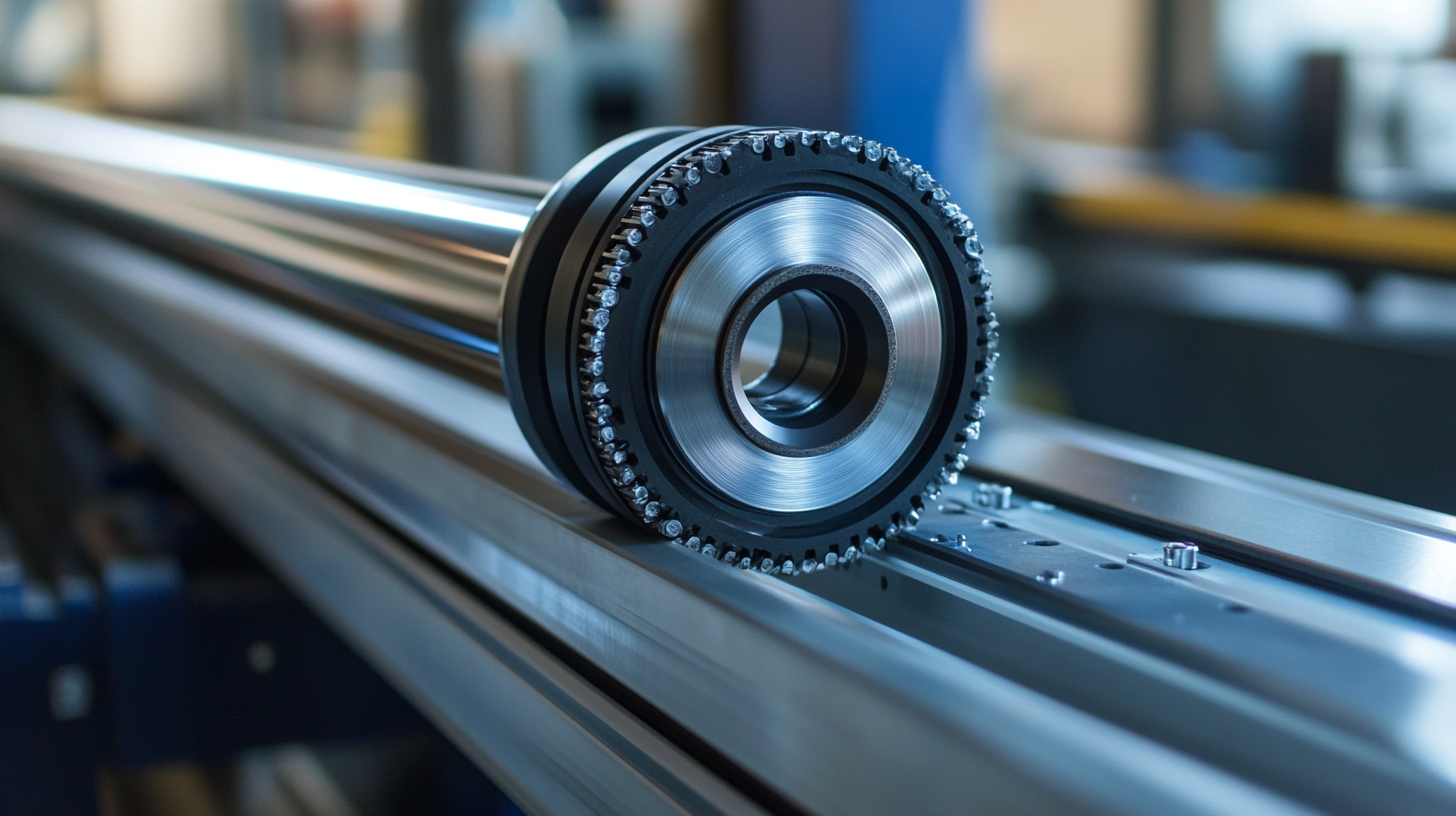

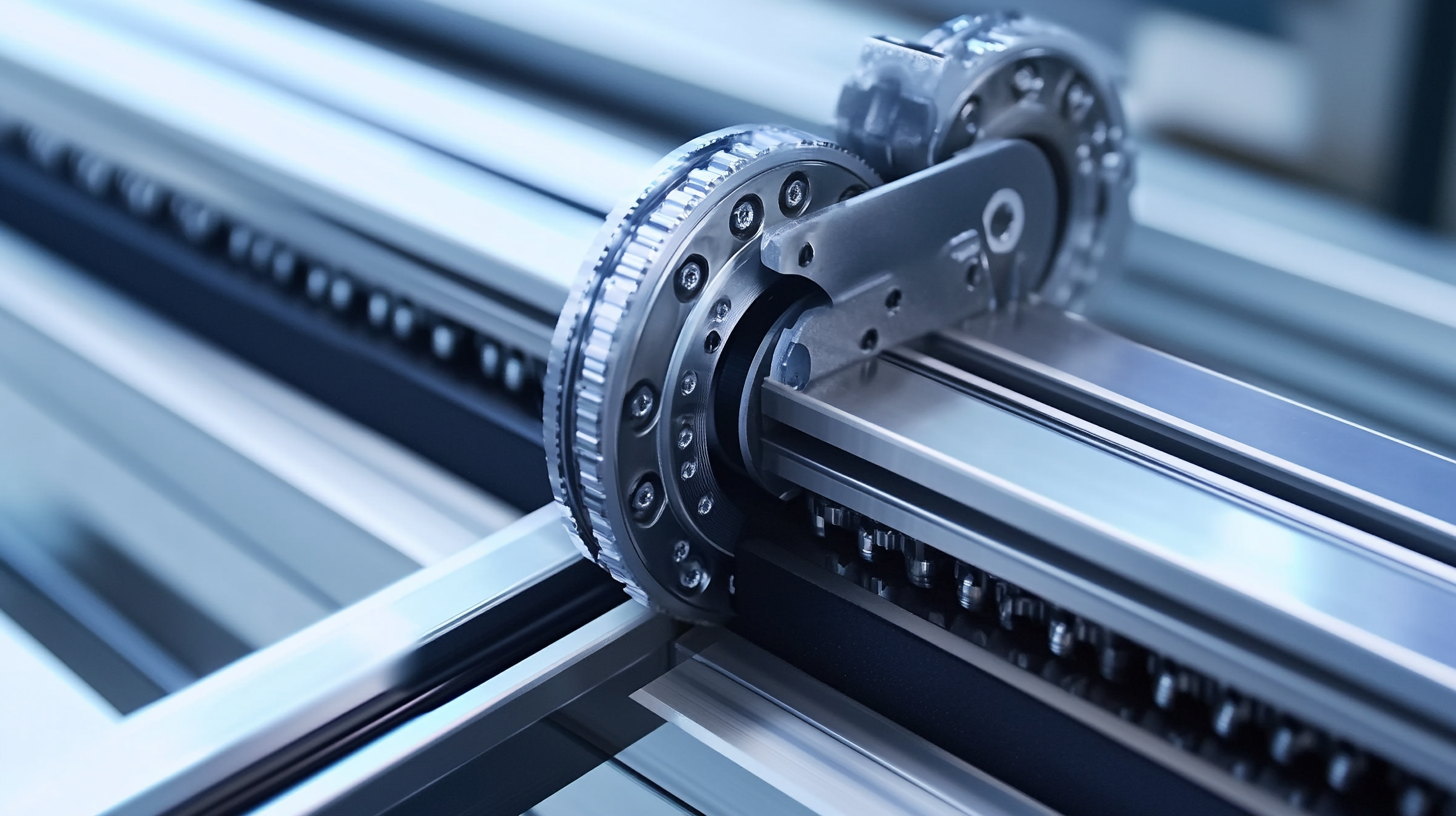

Key factors to consider when sourcing linear motion bearings include load capacity, material selection, and compatibility with existing systems. It’s essential to evaluate the performance criteria of bearings under varying operational conditions to ensure durability and reliability. Additionally, as automation continues to rise, the demand for tailored linear motion solutions will create a competitive edge for companies that prioritize strategic sourcing and the integration of state-of-the-art manufacturing technologies.

Furthermore, as industries increasingly adopt pneumatic actuation systems, currently valued at USD 51.71 billion with a growth forecast of 5.2% CAGR, there is a pressing need for hybrid solutions that incorporate both pneumatic actuators and linear motion bearings. This integration can lead to enhanced performance, reduced energy consumption, and improved overall system efficiency, emphasizing the importance of a comprehensive purchasing strategy focused on customization and innovation.

Streamlining Procurement Processes with Customized Solutions

In today's rapidly evolving marketplace, streamlining procurement processes has become essential for organizations striving for efficiency. Customized solutions, particularly in the realm of procurement, can help businesses overcome traditional barriers and achieve optimized purchasing strategies. For instance, recent partnerships in logistics highlight the importance of creating seamless entry points for procurement, enabling organizations to more effectively manage supply chains and reduce lead times.

The acquisition of sourcing platforms is another prime example of how companies are embracing tailored solutions to enhance procurement efficiency. By integrating advanced sourcing capabilities, manufacturers can better navigate their supplier networks and ensure a consistent flow of critical hardware. Moreover, innovative tools and features are emerging in the business landscape, empowering buyers to enjoy smoother transactions and improved data integrity. This transformation allows organizations to pivot swiftly in response to market demands while maintaining a competitive edge.

Overall, the shift towards customized procurement solutions is reshaping how organizations manage their purchasing processes. By prioritizing efficiency and adaptation, companies are not only streamlining their operations but also positioning themselves for future growth in an increasingly dynamic business environment.

Enhancing Operational Efficiency through Tailored Designs

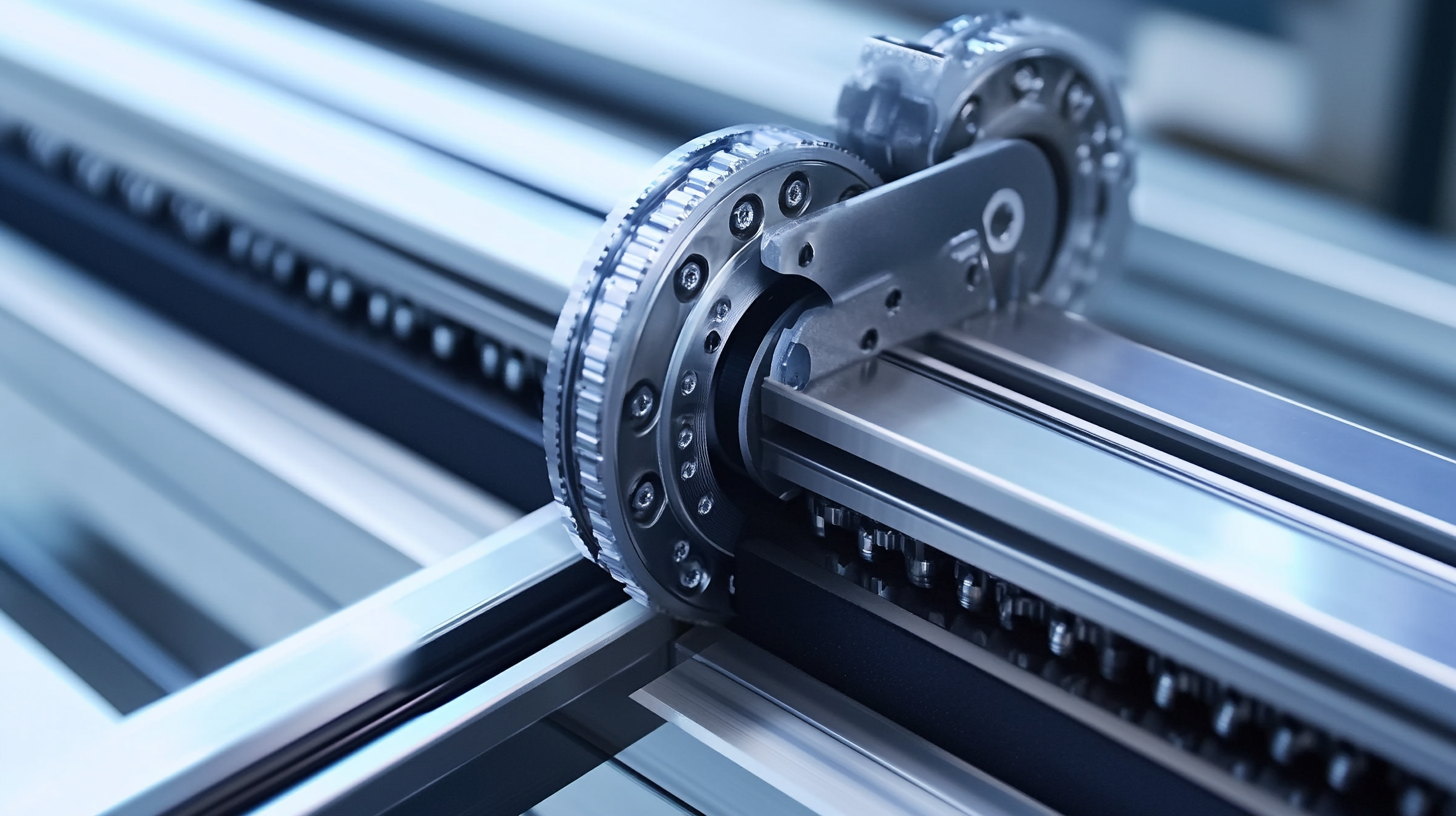

In today's fast-paced industrial landscape, operational efficiency has become a paramount concern for businesses striving to stay competitive. The adoption of custom linear motion bearings plays a crucial role in enhancing performance, particularly for organizations managing large-scale purchases. Tailored designs enable manufacturers to fine-tune specifications such as load capacity, travel distance, and environmental adaptability, thus ensuring that the bearings meet the unique operational demands of various applications.

Furthermore, custom linear motion bearings can significantly reduce downtime and maintenance costs. By optimizing the fit and function of these components, companies can minimize friction and wear while maximizing durability. This is especially beneficial in high-demand environments where machine reliability directly impacts productivity. Additionally, the ability to collaborate with suppliers in the design phase fosters innovation, resulting in solutions that not only fit existing systems but also enable future upgrades. The investment in tailored linear motion technology can ultimately lead to streamlined operations and a substantial increase in overall efficiency, fulfilling the diverse needs of modern manufacturing.

Unlocking Efficiency with Custom Linear Motion Bearings

This chart compares the efficiency rating of standard linear motion bearings against custom-designed solutions for large scale purchases. The custom bearings demonstrate a significant increase in efficiency, highlighting the benefits of tailored designs in operational settings.

Real-World Applications of Custom Linear Motion Bearings in Industry

In modern industry, the quest for efficiency often leads companies to seek innovative solutions, particularly in the realm of linear motion systems. Custom linear motion bearings play a pivotal role in a variety of applications, enabling seamless movement and precision in operations across sectors. From automotive manufacturing to aerospace and defense, these components are designed to meet specific demands, ensuring reliability and long-term performance under rigorous conditions.

The impact of custom linear motion bearings can be seen in large-scale manufacturing, where they enhance productivity by reducing friction and wear. In the automotive industry, for instance, specialized bearings facilitate the smooth operation of assembly lines, contributing to higher output and better vehicle performance. Similarly, in aerospace applications, these components are critical for supporting complex machinery, ensuring safety and efficiency in aircraft design and production. As industries evolve, the adoption of tailored solutions like custom bearings not only meets growing demand but also drives innovation, positioning companies for competitive advantage in an increasingly dynamic market.

Unlocking Efficiency with Custom Linear Motion Bearings

This pie chart illustrates the distribution of various real-world applications of custom linear motion bearings in different industries. The data showcases how each application contributes to overall usage, highlighting the versatility and efficiency of these components in large scale purchases.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us