What Are the Most Effective Bearing Life Extension Solutions

In the realm of industrial machinery, the longevity and performance of bearings play a critical role in overall operational efficiency. According to a report by the International Journal of Engineering Research and Applications, premature bearing failures can lead to significant downtime costs, often exceeding 20% of a plant's maintenance budget. As industries seek to enhance their productivity, Bearinga Life Extension Solutions have emerged as a focal point of innovation. Techniques such as advanced lubrication systems, condition monitoring, and predictive maintenance strategies not only prolong bearing lifespan but also optimize machinery functionality. A study from the Machinery Maintenance Institute highlights that implementing effective Bearing Life Extension Solutions can increase bearing life by up to 50%, further underscoring their importance in today’s manufacturing landscape. By harnessing these solutions, companies can mitigate risks associated with bearing failures and foster a more resilient operational framework.

Understanding Bearing Life and Its Importance in Machinery Performance

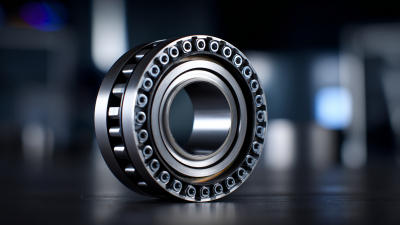

Bearings play a crucial role in the performance and efficiency of machinery. They are designed to reduce friction between moving parts, enabling smooth rotation and movement. Understanding the life of a bearing is essential for ensuring optimal machinery performance, as failing bearings can lead to equipment breakdowns, reduced productivity, and costly repairs. Factors influencing bearing life include load conditions, speed, lubrication quality, and environmental conditions. Proper management of these factors can significantly enhance the longevity of bearings.

Investing in preventive maintenance and monitoring techniques can lead to substantial improvements in bearing life. Implementing vibration analysis and temperature monitoring allows for early detection of potential issues, while proper lubrication practices ensure that bearings operate under ideal conditions. Additionally, selecting the right bearing type for specific applications further enhances performance and durability. By prioritizing understanding the life of bearings and their importance, companies can increase machinery reliability and reduce unscheduled downtimes.

Common Factors Affecting Bearing Longevity in Industrial Applications

When it comes to extending bearing life in industrial applications, understanding the common factors that influence bearing longevity is crucial. Operational conditions, such as load, speed, and environmental factors, play a significant role in determining how long bearings will last. High speeds and heavy loads can accelerate wear and tear, while contaminants like dust and moisture can cause damage over time. Therefore, it’s essential to regularly assess these conditions to ensure optimal performance and longevity.

Tips: Regular maintenance checks, including lubrication and alignment adjustments, can significantly enhance bearing life. Additionally, investing in high-quality seals can help keep contaminants out and reduce the risk of premature failure.

Another critical factor is temperature control. Bearings that operate in extreme temperatures may suffer from thermal expansion or degradation of lubricants, ultimately impacting their performance. Implementing effective cooling systems or selecting bearings designed for high-temperature applications can mitigate these issues.

Tips: Be sure to monitor temperature levels consistently and choose appropriate lubrication methods that are stable under varying temperature conditions to enhance bearing reliability.

Proven Techniques for Enhancing Bearing Lubrication and Cooling

When it comes to extending the life of bearings, enhancing lubrication and cooling is crucial. Recent advancements highlight the development of sustainable greases made from natural sources, such as jojoba oil combined with plant waste-derived nanoadditives. These innovative greases not only improve lubrication performance but also address environmental concerns by utilizing waste materials, thus promoting sustainability in bearing operations.

Tips: To maximize the benefits of advanced lubricants, consider incorporating nanolubricants that leverage the properties of various nanoparticles. These nanoadditives can significantly enhance tribological performance, especially under extreme operational conditions such as in electric and hybrid vehicles.

Furthermore, techniques like cryo-lubrication are proving to be game-changers in machining processes, reducing the environmental footprint of traditional methods. By optimizing cooling strategies, such as implementing hybrid lubrication systems, manufacturers can achieve improved bearing performance while also promoting resource equity. Emphasizing these modern solutions can lead to more efficient production processes and extended bearing lifespans.

Most Effective Bearing Life Extension Solutions

Innovative Technologies for Monitoring and Predicting Bearing Wear

Innovative technologies for monitoring and predicting bearing wear have become essential in extending the lifespan of bearings in various applications. Traditional methods of maintenance often rely on scheduled inspections and replacements, which may not be the most efficient approach. With advancements in condition monitoring systems, industries can now employ real-time data analytics to evaluate the health of bearings continuously. These systems utilize sensors that measure temperature, vibration, and noise levels to provide insights into bearing performance, enabling proactive maintenance interventions before a complete failure occurs.

Furthermore, predictive analytics powered by machine learning algorithms are transforming how companies approach bearing maintenance. By analyzing historical data and operating conditions, these algorithms can forecast potential wear rates and failure points, allowing businesses to optimize maintenance schedules and reduce downtime. Moreover, the integration of Internet of Things (IoT) technology facilitates remote monitoring, which can be particularly beneficial for operations in hard-to-reach locations. This innovative approach not only minimizes operational disruptions but also maximizes equipment efficiency, ultimately leading to significant cost savings and improved reliability.

What Are the Most Effective Bearing Life Extension Solutions - Innovative Technologies for Monitoring and Predicting Bearing Wear

| Technology |

Description |

Benefits |

Typical Application |

| Vibration Monitoring |

Measures vibrations in bearings to detect wear and misalignment. |

Early fault detection, reduced downtime, improved reliability. |

Industrial machinery, pumps, and motors. |

| Temperature Monitoring |

Tracks temperature changes in bearings to predict failures. |

Prevention of overheating, extended bearing life. |

Compressors, turbines, and HVAC systems. |

| Lubrication Analysis |

Analyzes lubricant condition to ensure optimal lubrication. |

Reduces friction, prevents wear, lowers maintenance costs. |

Gearboxes, conveyor systems, and automotive applications. |

| Ultrasonic Testing |

Uses high frequency sound waves to detect defects within bearings. |

High sensitivity to small defects, non-invasive inspection. |

Aerospace, automotive, and power generation industries. |

| Predictive Analytics |

Data-driven approach using machine learning models to foresee bearing wear. |

Optimizes maintenance schedules, prolongs equipment life. |

Heavy machinery, refining processes, and mining equipment. |

Best Practices for Implementing Preventive Maintenance to Extend Bearing Life

Implementing effective preventive maintenance is crucial to extending bearing life and enhancing machinery reliability. One approach is predictive maintenance, which utilizes real-time data from IoT sensors to forecast potential failures, enabling timely interventions before breakdowns occur. Studies show that predictive maintenance can significantly reduce downtime and maintenance costs, leading to extended equipment lifespan and improved operational efficiency.

Tips for extending bearing life include adopting best lubrication practices, as poor lubrication is a common cause of bearing failure. Implementing standards, such as those outlined in ICML 55.1, has demonstrated a reduction in breakdowns and maintenance costs. Additionally, vibration signal analysis provides insight into early signs of faults in rolling bearings, allowing for proactive diagnostics and repairs.

A strong maintenance culture plays a pivotal role in these efforts. Fostering this mindset among staff enhances engagement and promotes adherence to preventive measures. Total Productive Maintenance (TPM) strategies also contribute by integrating performance measurement methodologies, ensuring that maintenance practices align with overall production goals and drive continuous improvement.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us