Unlocking Efficiency: Top Reasons to Choose 6200 Series Bearings In Stock for Your Manufacturing Needs

In the fast-paced world of manufacturing, maximizing efficiency while minimizing downtime is crucial for maintaining a competitive edge. One of the key components that can significantly impact operational effectiveness is the choice of bearings. Recent industry reports indicate that bearing failures account for a substantial percentage of machinery downtime, with estimates suggesting that unplanned downtime can cost manufacturers up to

$250,000 per hour. In this context, the

6200 Series Bearings In Stock emerge as a pivotal solution.

These bearings not only offer superior performance due to their robust design and high-quality materials but also ensure immediate availability, thus reducing lead times and fostering smooth production processes. By unlocking the potential of

6200 Series Bearings In Stock, manufacturers can streamline their operations and enhance overall productivity, making them a wise investment for any operational improvement strategy.

The Significance of 6200 Series Bearings in Modern Manufacturing

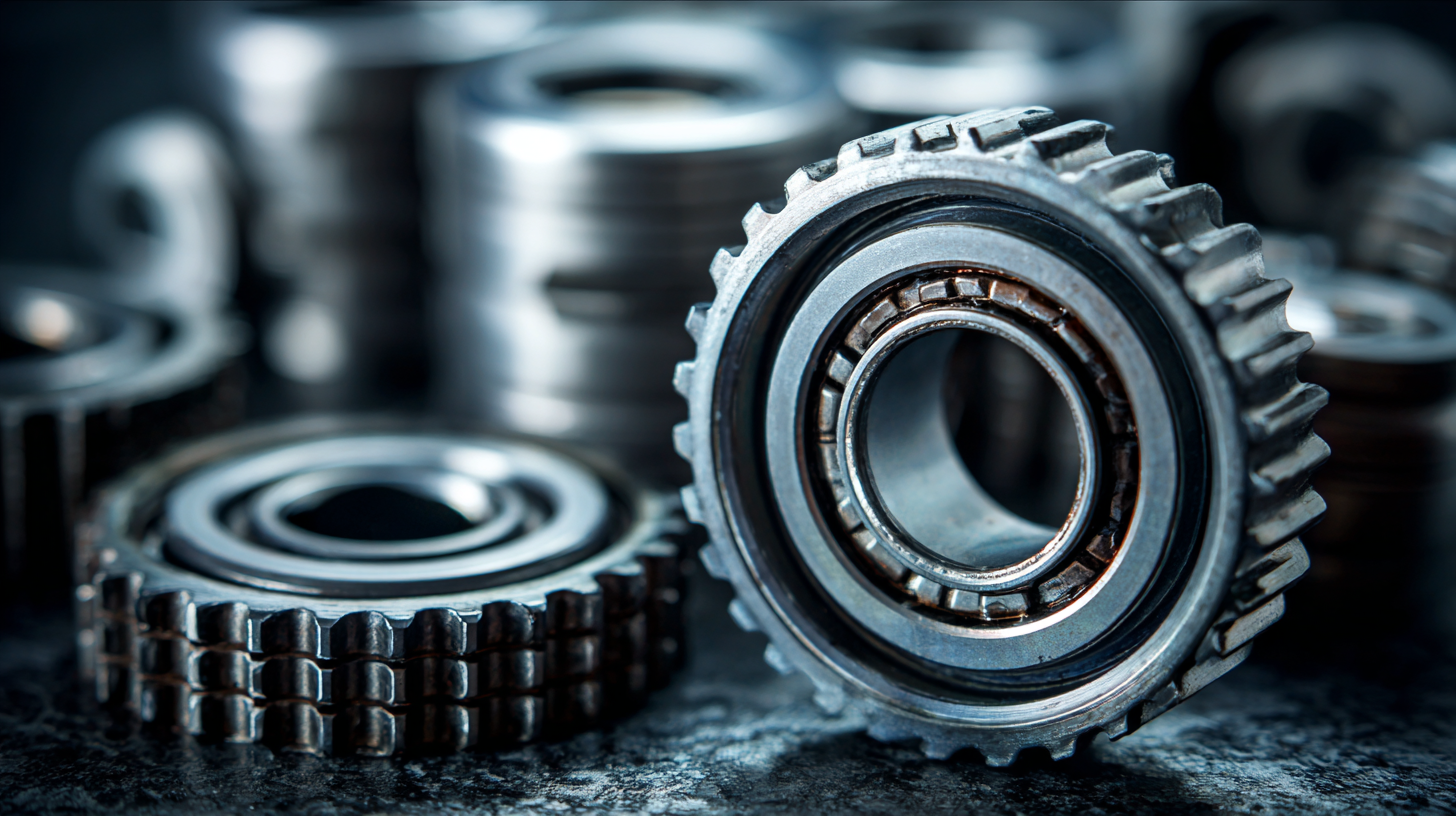

In modern manufacturing, the efficiency and reliability of machinery play a crucial role in the overall productivity and success of operations. The 6200 Series Bearings have emerged as a significant component in various applications, providing remarkable performance that aligns with the demands of contemporary manufacturing environments. Their design, featuring robust construction and precision engineering, ensures optimized functionality, thereby reducing downtime and maintenance costs.

As industries look towards aggressive growth strategies, similar to the ambitious plans announced by local manufacturers targeting substantial revenue increases, the selection of high-quality components like the 6200 Series Bearings becomes paramount. These bearings not only enhance operational efficiency but also support manufacturers in adapting to rapid changes in production scales and technological advancements. By investing in such reliable components, manufacturers can position themselves to capitalize on market opportunities while minimizing disruptions to their workflows.

Unlocking Efficiency: Top Reasons to Choose 6200 Series Bearings In Stock for Your Manufacturing Needs

| Feature |

Description |

Advantages |

Application Areas |

| High Load Capacity |

Designed to support high radial and axial loads. |

Ensures durability and longevity in demanding environments. |

Automotive, industrial machinery, and agriculture. |

| Versatile Design |

Available in various sizes and configurations for different applications. |

Flexibility to meet specific manufacturing requirements. |

Conveyors, fans, and compressors. |

| Reduced Friction |

Sealed or open designs that minimize friction between components. |

Improves energy efficiency and decreases operational costs. |

Electric motors, pumps, and machine tools. |

| Easy Maintenance |

Simple installation and maintenance processes. |

Reduces downtime and maintenance costs. |

Manufacturing plants and automated systems. |

| Temperature Tolerance |

Function effectively in a wide range of temperatures. |

Stable performance in harsh environments. |

Mining, oil & gas, and heavy equipment. |

Key Advantages of Using 6200 Series Bearings for Operational Efficiency

The 6200 series bearings are increasingly becoming the go-to choice for manufacturers looking to enhance operational efficiency. These bearings are designed with precision and durability in mind, providing smooth performance even under heavy loads. Their versatility makes them suitable for various applications, from industrial machinery to household equipment. By investing in 6200 series bearings, manufacturers can significantly reduce the frequency of replacements and maintenance, ultimately leading to cost savings.

Tips: When selecting 6200 series bearings for your operations, consider the specific load and speed requirements of your machinery. Ensure that you choose the right lubrication method to maximize their lifespan and performance. Additionally, always double-check compatibility with existing equipment to avoid any operational hiccups.

Another advantage of the 6200 series is their ability to operate in a range of environmental conditions. These bearings can withstand extreme temperatures and resist contaminants, making them ideal for challenging manufacturing environments. This resilience not only prolongs their service life but also enhances overall system reliability, reducing unexpected downtime and maintenance needs.

Tips: Regularly inspect bearings for signs of wear or damage early on. Implementing a proactive maintenance schedule can help you catch issues before they lead to larger problems, ensuring that your manufacturing processes run smoothly.

Comparison of 6200 Series Bearings with Alternative Bearing Options

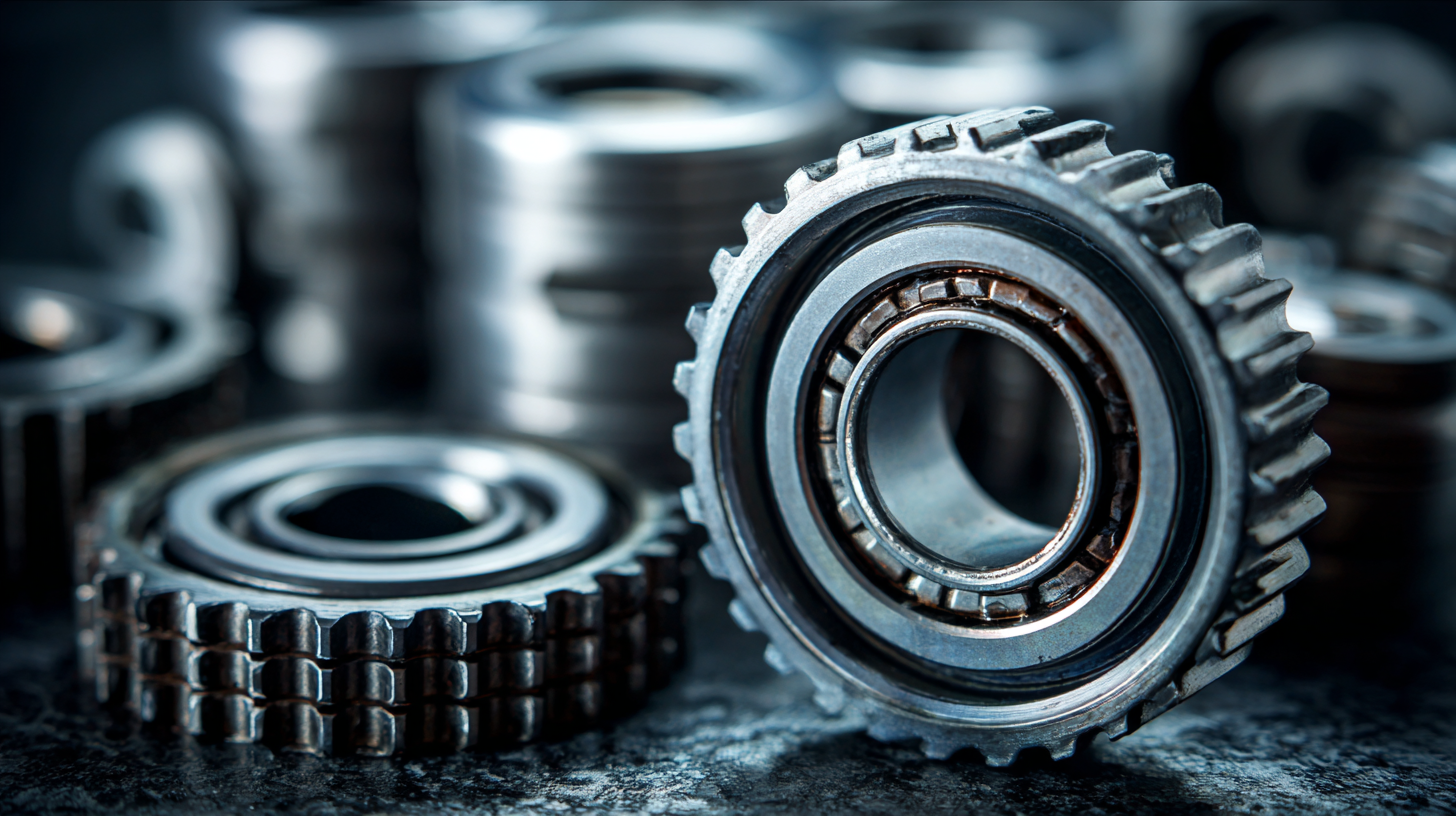

When considering bearing options for manufacturing, the 6200 series bearings stand out for their reliability and efficiency, offering noteworthy advantages over alternative bearings such as the 6000 and 6300 series. According to industry data, the 6200 series exhibits superior load capacities and reduced friction, resulting in enhanced performance and longer service life. A report by the International Journal of Manufacturing Technology highlights that using 6200 series bearings can improve operational efficiency by up to 15%, especially in applications requiring precision and durability.

Tip: When selecting bearings, consider the specific load and speed requirements of your application. The 6200 series is particularly beneficial for medium load applications but may not suit heavy-duty environments compared to the 6300 series, which excels in high-load scenarios.

Additionally, the 6200 series bearings are designed for easy installation and maintenance. The unique design minimizes the risk of misalignment, which can lead to premature failure. Data from the Bearing Manufacturers Association indicates that proper selection and installation can reduce maintenance costs by approximately 20%, making the 6200 series a cost-effective option over time.

Tip: Regularly monitor bearing conditions and alignments to extend lifespan and avoid unexpected downtimes. Investing in quality, like the 6200 series, can yield significant long-term savings, making it a wise choice for smart manufacturing strategies.

Cost-Effectiveness of Stocking 6200 Series Bearings for Production

When it comes to optimizing production operations, the cost-effectiveness of stocking 6200 series bearings cannot be overstated. These bearings provide a reliable solution for various manufacturing needs, ensuring smooth and efficient machinery performance. By keeping these bearings in stock, companies can significantly reduce both lead times and downtime, which directly contributes to cost savings. The 6200 series is known for its versatility and robustness, making it suitable for a wide range of applications, thereby minimizing the need for multiple bearing types in inventory.

Furthermore, the economies of scale achieved through bulk purchasing of 6200 series bearings further enhance cost efficiency. Manufacturers can take advantage of favorable pricing when buying in large quantities, ultimately lowering their per-unit costs. This strategic approach not only helps in managing operational budgets but also allows for better resource allocation towards other critical areas of production. In today's competitive market, the combination of reliable performance and cost savings makes the 6200 series bearings a smart choice for manufacturers looking to streamline their processes and enhance overall productivity.

Maintaining Quality and Performance with 6200 Series Bearings in Stock

When it comes to manufacturing, the choice of bearings can significantly impact overall efficiency and product quality. The 6200 Series Bearings are renowned for their robustness and consistent performance, making them a top choice for various industrial applications. These bearings are designed to meet high load-carrying capacities while maintaining low friction, which enhances operational efficiency. By selecting 6200 Series Bearings in stock, manufacturers can ensure they have access to high-quality components that will perform reliably under demanding conditions.

Moreover, the reliability of the 6200 Series Bearings is complemented by their versatility. Available in multiple configurations, they can easily fit into different machinery setups, ensuring compatibility and seamless integration. The precision engineering of these bearings minimizes wear and tear, prolonging the lifespan of the equipment they support. This means that not only do manufacturers benefit from improved efficiency, but they also maintain high standards of quality and performance throughout their production processes, resulting in superior end products.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us