Unleashing Excellence in Manufacturing with Top SKF Equivalent Bearings from World Class Chinese Factories

In an era where manufacturing efficiency and product quality are paramount, the demand for high-performance components like SKF Equivalent Bearings is surging. According to a recent report by MarketsandMarkets, the global bearing market is projected to reach USD 100 billion by 2025, driven by advancements in technology and increasing automation across various industries. Chinese factories are poised to play a pivotal role in this landscape, leveraging state-of-the-art manufacturing techniques to produce top-quality SKF Equivalent Bearings that meet international standards. With a focus on innovation and excellence, leading Chinese manufacturers are setting new benchmarks in the bearing industry, ensuring that companies can enhance operational performance while reducing costs. This blog will explore the latest industry trends and provide actionable insights on how businesses can harness the potential of SKF Equivalent Bearings to achieve unparalleled excellence in manufacturing.

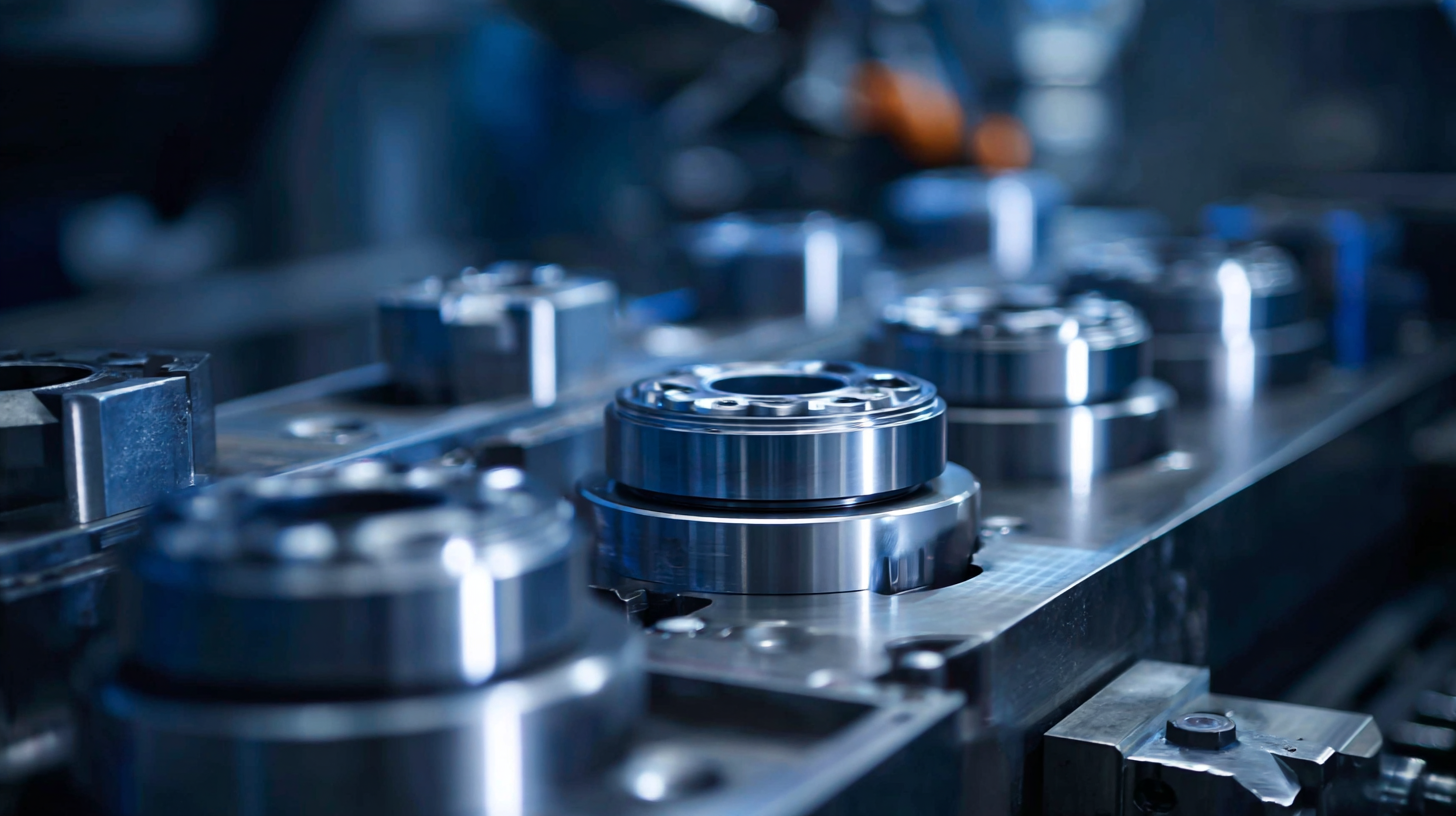

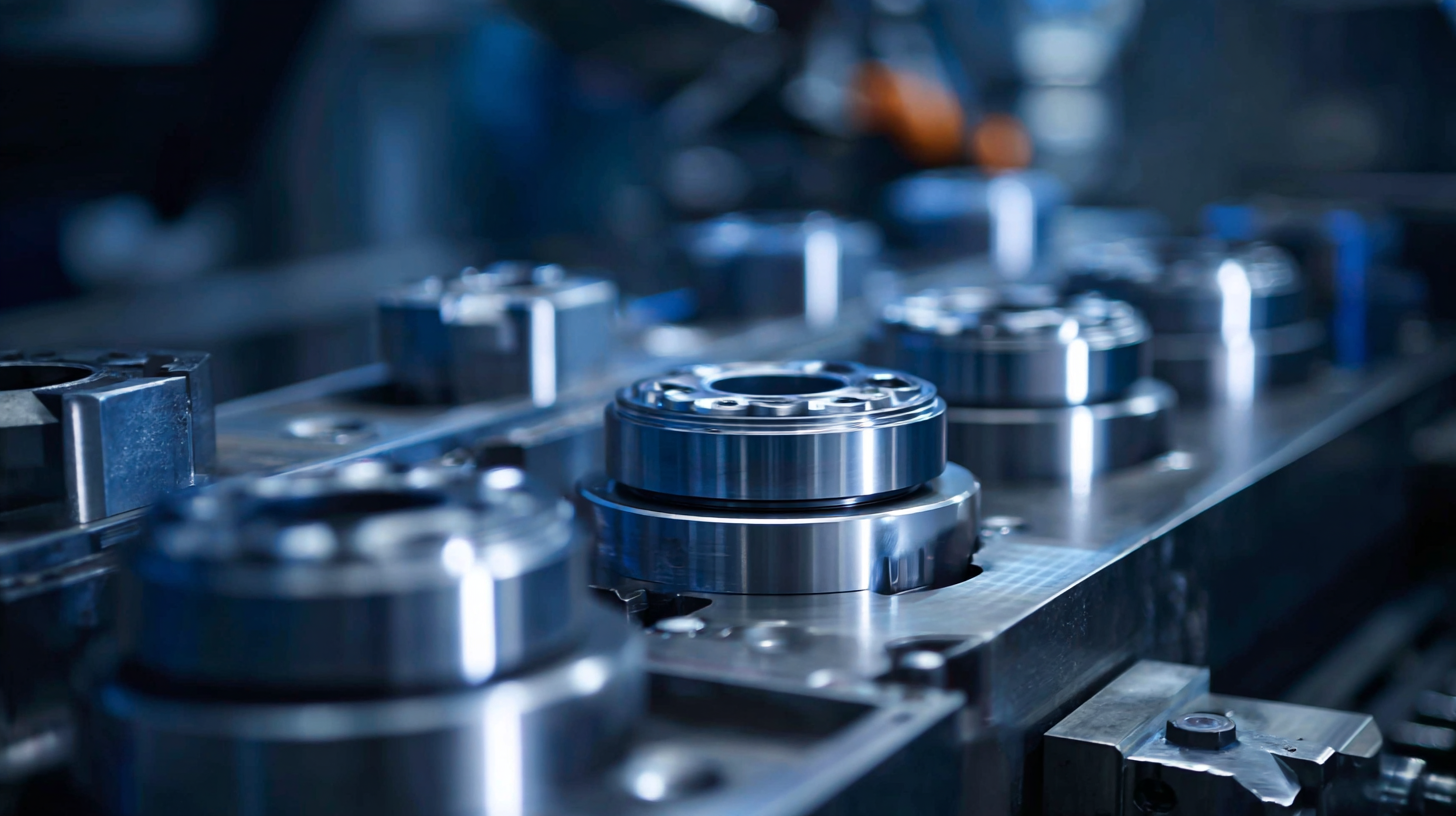

Understanding the Importance of Bearing Quality in Manufacturing

In the world of manufacturing, the quality of components directly impacts the efficiency and longevity of machinery.

Bearings, as essential elements in various mechanical systems, play a crucial role in reducing friction, supporting loads, and ensuring smooth operation.

According to a report by the International Organization for Standardization (ISO), machinery downtime due to bearing failures can lead to losses estimated at over $500 billion annually.

Hence, investing in high-quality bearings, particularly SKF equivalent bearings produced by reputable Chinese factories, is vital for maintaining operational excellence.

Bearings, as essential elements in various mechanical systems, play a crucial role in reducing friction, supporting loads, and ensuring smooth operation.

According to a report by the International Organization for Standardization (ISO), machinery downtime due to bearing failures can lead to losses estimated at over $500 billion annually.

Hence, investing in high-quality bearings, particularly SKF equivalent bearings produced by reputable Chinese factories, is vital for maintaining operational excellence.

When selecting bearings, it's essential to consider several key factors. First, ensure that the bearings meet recognized international standards,

such as ISO 9001 certification. Secondly, comparing the material properties and design features against industry benchmarks

can reveal significant differences in performance and longevity. It's also advisable to work closely with suppliers who are invested in

quality assurance and continuous improvement processes.

Tip: Regular maintenance routines can greatly extend the life of your bearings.

Implement a schedule for inspection and lubrication to avoid unexpected failures.

Additionally, leveraging advanced technologies in bearing manufacturing, such as friction-reducing coatings

and customized design solutions, can lead to improved efficiency. By prioritizing bearing quality,

manufacturers can not only enhance productivity but also contribute to the sustainability of their operations.

Tip: Invest in smart bearing solutions that offer real-time monitoring to anticipate failures before they occur,

maximizing uptime and reducing repair costs.

Essential Features of Top SKF Equivalent Bearings

In the competitive landscape of manufacturing, the choice of bearings is crucial for operational efficiency and product quality. Top SKF equivalent bearings sourced from world-class Chinese factories have emerged as a game-changer, blending advanced engineering and cost-effectiveness. These bearings exhibit essential features, including high load capacity, superior wear resistance, and enhanced reliability, making them an invaluable asset in various industrial applications.

When selecting bearings, it's important to consider factors such as materials and design. Ensure that the bearings are made from high-quality materials that provide both durability and resilience under heavy loads. Additionally, look for designs that minimize friction and heat generation, which can extend the lifespan of the bearings and improve machinery performance.

Another tip is to assess supplier credibility by seeking those with robust quality control processes and certifications. This step ensures that the bearings meet international standards for performance and safety, thus reducing the risk of failure and downtime in manufacturing operations. Emphasizing these features will help manufacturers leverage the benefits of top SKF equivalent bearings and sustain excellence in production.

Unleashing Excellence in Manufacturing with Top SKF Equivalent Bearings from World Class Chinese Factories - Essential Features of Top SKF Equivalent Bearings

| Feature |

Description |

Advantages |

Applications |

| Material Quality |

High-grade steel and polymer materials |

Enhanced durability and performance |

Industrial machinery, automotive |

| Precision Design |

Tight tolerances and specifications |

Improved efficiency and reduced wear |

Aerospace, robotics |

| Sealing Technology |

Innovative sealing solutions |

Protection against contamination |

Heavy machinery, manufacturing |

| Heat Resistance |

Engineered for high-temperature operations |

Stable performance in extreme conditions |

Automotive, energy sectors |

| Lubrication Systems |

Advanced lubrication systems |

Reduced friction and increased life span |

Manufacturing equipment, conveyors |

| Vibration Resistance |

Designed to minimize vibration |

Better stability and performance |

Construction, transportation |

Evaluating Chinese Manufacturers: Key Selection Criteria

In the pursuit of manufacturing excellence, selecting the right suppliers is crucial, especially when considering top bearings from Chinese factories. Evaluating manufacturers requires a keen focus on key selection criteria that underpin quality and reliability. Factors such as production capabilities, quality control measures, and industry certifications play vital roles in ensuring that the products meet international standards. Furthermore, understanding the company’s commitment to innovation and sustainability can also provide insight into their long-term viability in a competitive market.

**Tips:** When assessing a Chinese manufacturer, prioritize those that have established quality management systems in place. An additional way to gauge reliability is to investigate customer reviews and feedback, as these can reveal valuable insights into the manufacturer’s reputation and performance. It’s also beneficial to consider manufacturers that have experience in export markets, as this often reflects a greater adaptability to meet diverse regulatory requirements and customer expectations.

Maintaining open communication during the evaluation process enhances transparency and trust. Engaging directly with suppliers allows for a better understanding of their capabilities and can lead to stronger partnerships. By leveraging these selection criteria, businesses can ensure they are partnering with top-tier manufacturers that contribute to the excellence in their supply chain.

The Role of Advanced Technology in Bearing Production

In today’s competitive manufacturing landscape,

advanced technology plays a pivotal role in the production of top SKF equivalent bearings.

World-class Chinese factories are embracing cutting-edge innovations, such as

automation and

artificial intelligence,

to enhance the precision and efficiency of their manufacturing processes.

These technologies allow for

improved quality control,

reduced production times,

and the ability to produce complex designs that meet diverse industry needs.

Tips for manufacturers looking to upgrade their bearing production include investing in

modern machinery that incorporates smart features.

By incorporating

sensors and

IoT capabilities,

manufacturers can monitor their equipment in real-time, leading to

predictive maintenance and minimizing downtime.

Additionally, utilizing

quality management software

can streamline the production workflow, ensuring that every bearing meets

rigorous quality standards before reaching the market.

Another important tip is to foster a culture of

continuous improvement among the workforce.

Training employees to understand and utilize new technologies not only boosts morale but also facilitates

innovation at every level of production.

Encouraging

teamwork in problem-solving can help factories adapt more swiftly to changes in demand and technology,

cementing their status as leaders in the global market for bearing production.

Maximizing Operational Efficiency with the Right Bearings

In the rapidly evolving landscape of manufacturing, the right bearings play a crucial role in maximizing operational efficiency. As industries increasingly adopt innovative technologies, such as modular sorting systems and conveyor components, the demand for high-performance bearings has surged. Reports indicate that the miniature ball bearings market is expected to reach USD 2.25 billion in revenue by 2025, driven by their critical applications across various sectors, including automotive and renewable energy.

Moreover, as we witness a significant shift towards electric vehicles (EVs), optimizing the performance of traction motors through advanced bearing technologies becomes imperative. The transition to cleaner transportation not only enhances mechanical efficiency but also contributes to sustainability goals. Manufacturers are now presented with unique challenges that require integrating energy-efficient solutions in their designs while also addressing maintenance concerns. The maintenance paradox highlights the need to minimize downtime while maximizing productivity—a challenge that can be effectively tackled with high-quality,

SKF-equivalent bearings from world-class manufacturers. These bearings ensure reliability and performance, enabling manufacturers to achieve their operational excellence objectives.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us

Bearings, as essential elements in various mechanical systems, play a crucial role in reducing friction, supporting loads, and ensuring smooth operation.

According to a report by the International Organization for Standardization (ISO), machinery downtime due to bearing failures can lead to losses estimated at over $500 billion annually.

Hence, investing in high-quality bearings, particularly

Bearings, as essential elements in various mechanical systems, play a crucial role in reducing friction, supporting loads, and ensuring smooth operation.

According to a report by the International Organization for Standardization (ISO), machinery downtime due to bearing failures can lead to losses estimated at over $500 billion annually.

Hence, investing in high-quality bearings, particularly