Unleashing Global Excellence with China's Best Low Noise Electric Motor Bearings

In the rapidly evolving landscape of global manufacturing, the demand for high-performance components such as Low-Noise Electric Motor Bearings is at an all-time high. According to a recent market report by Grand View Research, the global electric motor bearing market is projected to reach USD 23.5 billion by 2027, driven by advancements in technology and increasing industrial automation. As industries worldwide strive for quieter and more efficient operations, the importance of low-noise solutions cannot be overstated. China, known for its robust manufacturing capabilities, is leading the charge in producing top-quality Low-Noise Electric Motor Bearings that meet international standards. By harnessing advanced technologies and innovative practices, Chinese manufacturers are not only enhancing product performance but also ensuring environmental sustainability. As we delve deeper into the capabilities and benefits of these bearings, it becomes clear that excellence in manufacturing is set to be redefined from China, serving a global market that continues to innovate and grow.

The Rise of Low Noise Electric Motor Bearings in China

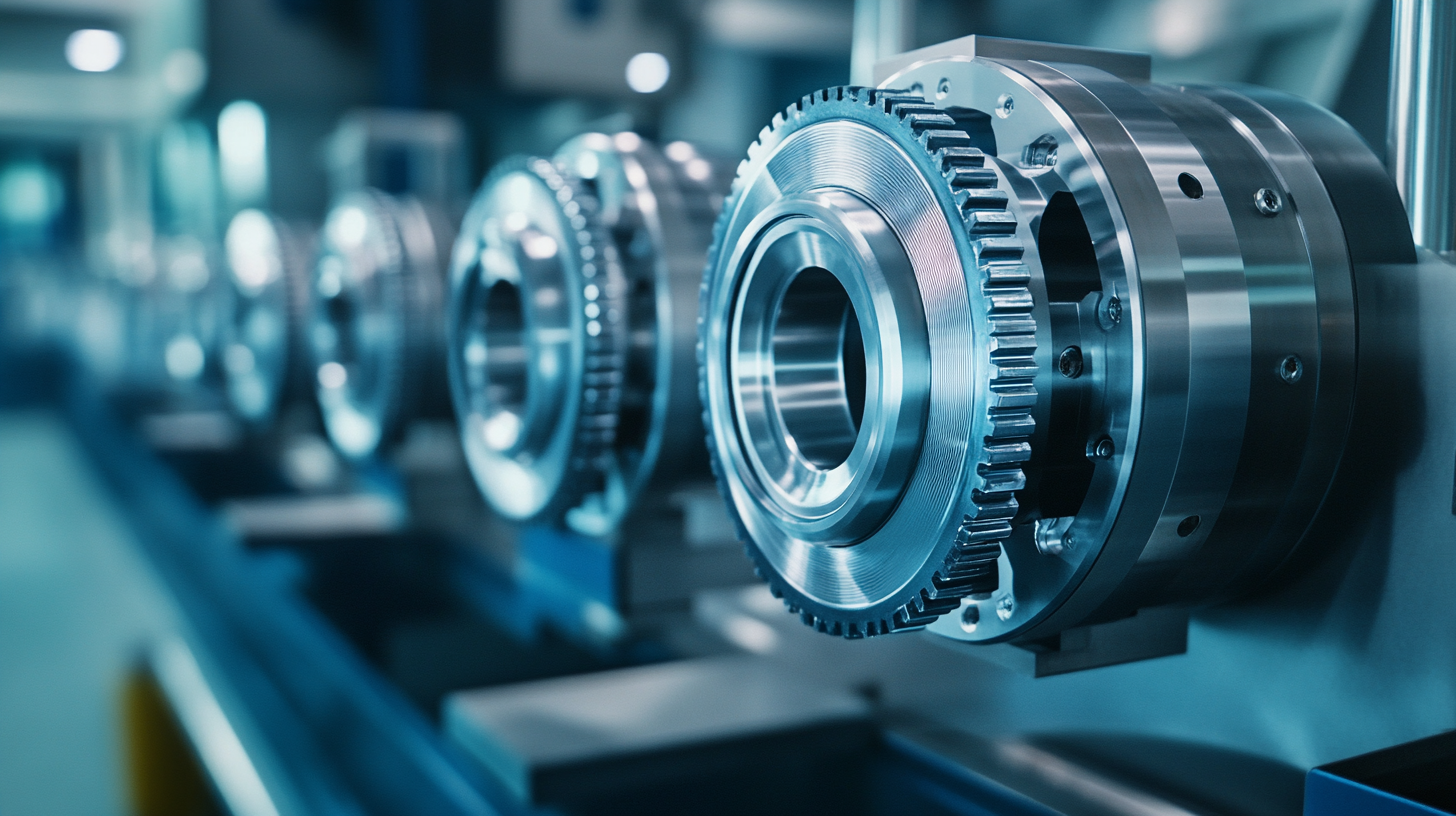

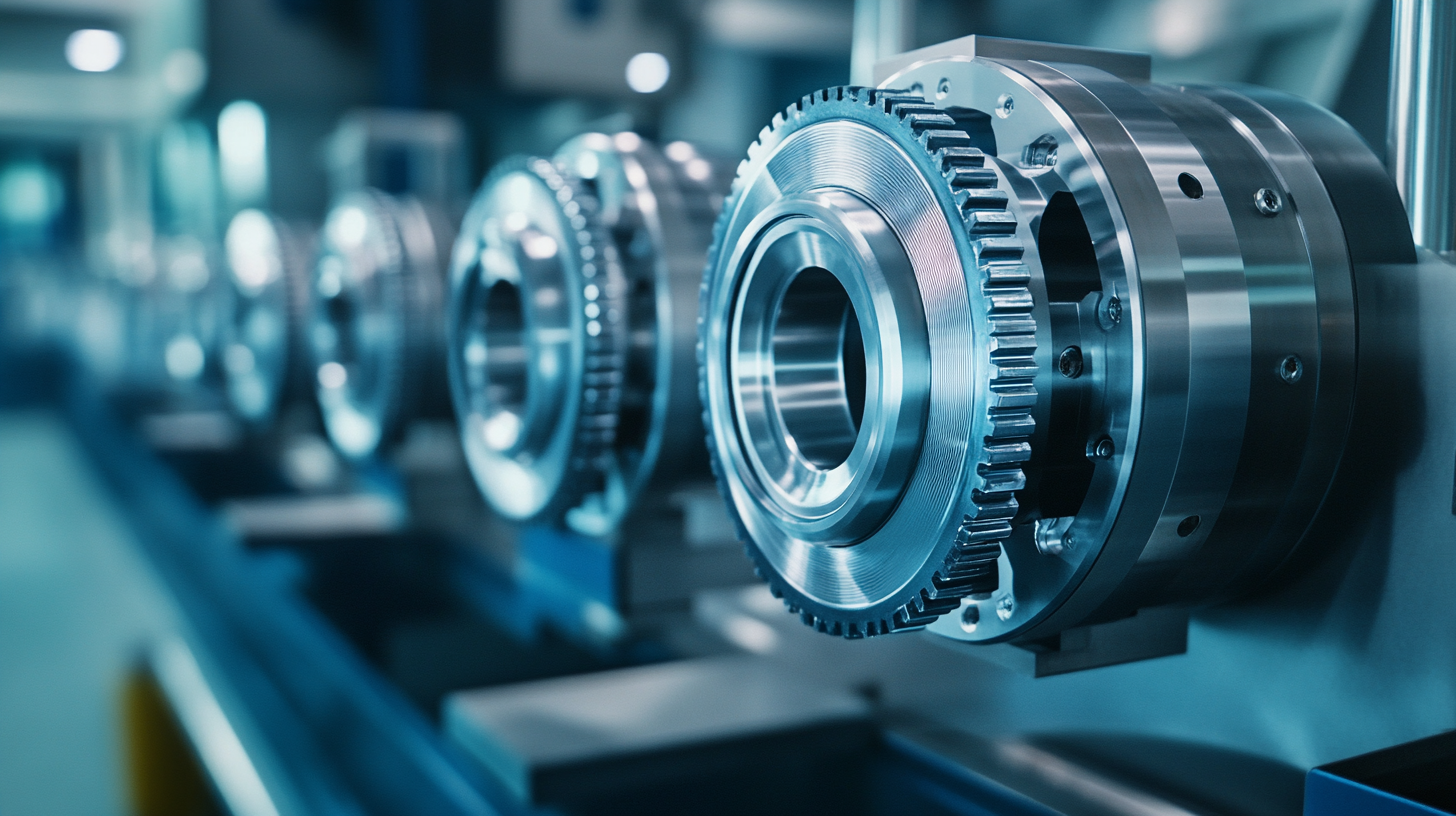

In recent years, China's manufacturing sector has witnessed a remarkable surge in the production of

low noise electric motor bearings. This transformation is not merely a trend but a response to the growing demand for quieter, more efficient machinery in various industries, including automotive, home appliances, and industrial equipment. As technology evolves, the emphasis has shifted towards optimizing performance while reducing acoustic emissions, making low noise bearings a pivotal component in modern electric motor designs.

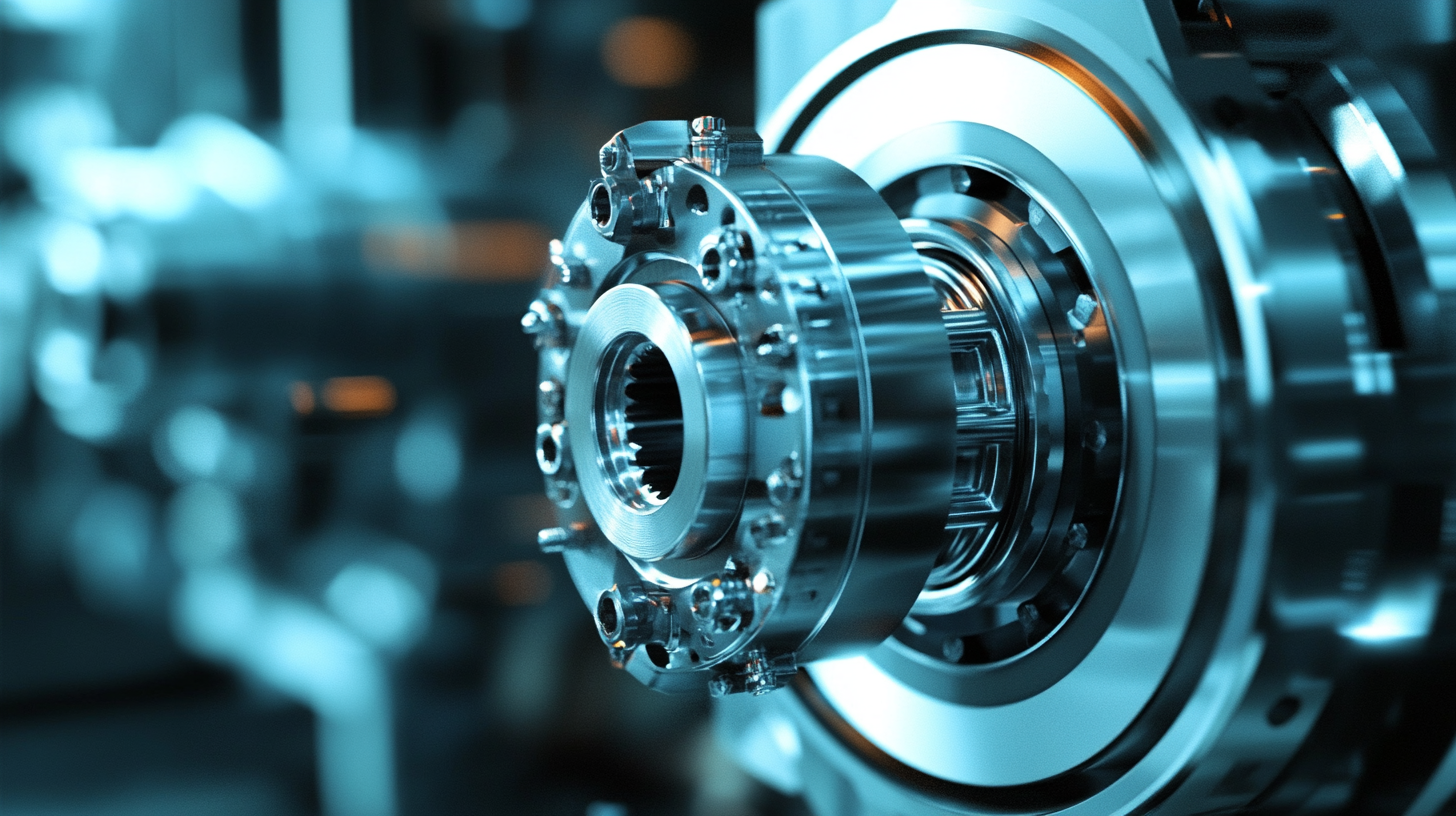

When selecting low noise electric motor bearings, it's beneficial to consider a few key tips. Firstly, ensure that the bearings are designed specifically for

low noise applications, often indicated by their materials and construction methods. Secondly, pay attention to the bearing's lubrication system, as adequate lubrication can significantly mitigate operational noise. Finally, evaluate the manufacturer's reputation and track record in producing high-quality, reliable components, as this can impact both performance and longevity.

As China continues to rise as a leader in this niche market, manufacturers are innovating to sustain excellence in low noise bearing technology. This advancement not only caters to the domestic market but also positions China as a competitive player on the global stage, showcasing the potential for amplified growth in international exports and collaborations.

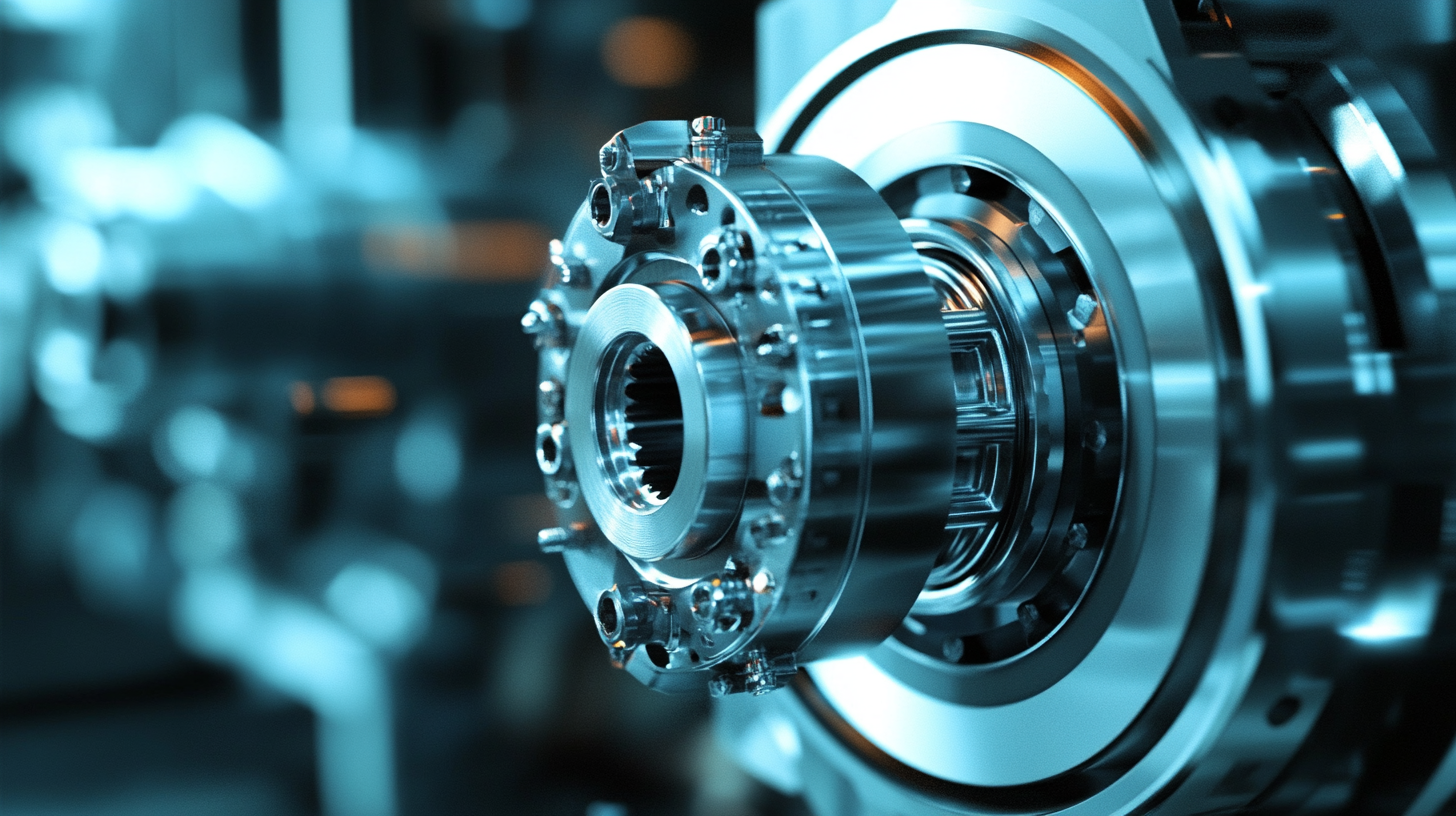

Key Features of China’s Leading Low Noise Electric Motor Bearings

China’s leading low noise electric motor bearings have gained significant recognition in the global market, primarily due to their innovative design and superior performance. According to a report by MarketsandMarkets, the electric motor bearings market is projected to reach USD 25.23 billion by 2025, with a substantial demand for low noise variants driven by the increasing need for quiet operation in various applications, including domestic appliances and automotive industries. These bearings are engineered to minimize vibration and friction, resulting in quieter operation while enhancing overall efficiency.

One of the key features of China's top low noise electric motor bearings is their advanced material technology. Utilizing high-grade steel and specialized polymers, these bearings are designed to withstand harsh environmental conditions, thereby extending their lifespan. The International Journal of Precision Engineering and Manufacturing noted a 15% improvement in durability over standard bearings, directly translating to lower maintenance costs for manufacturers. Additionally, the incorporation of precision manufacturing techniques ensures tighter tolerances, further minimizing operational noise. As industries strive for greater energy efficiency and noise reduction, these bearings align perfectly with the global trend toward sustainable and environmentally friendly technologies.

Applications and Benefits of Low Noise Bearings in Global Markets

The global demand for low noise bearings is on the rise, driven by the increasing need for quieter, more efficient machinery across various applications. As industries strive to enhance operational efficiency while minimizing noise pollution, China's advanced low noise electric motor bearings stand out as a pivotal solution. These bearings are ideal for use in air compressors, where minimizing sound without compromising performance is critical. With the air compressor market projected to grow significantly, innovations in bearing technology will play a crucial role in meeting the needs of this expanding sector.

Moreover, the benefits of low noise bearings extend beyond just performance; they also contribute to the sustainability goals that industries are increasingly prioritizing. By reducing friction and energy loss, these bearings enable machinery to operate more efficiently, leading to lower energy consumption and production costs. As China positions itself as a leader in innovation, the integration of low noise electric motor bearings into global markets not only enhances product offerings but also aligns with the broader trends of industrial modernization and environmental consciousness.

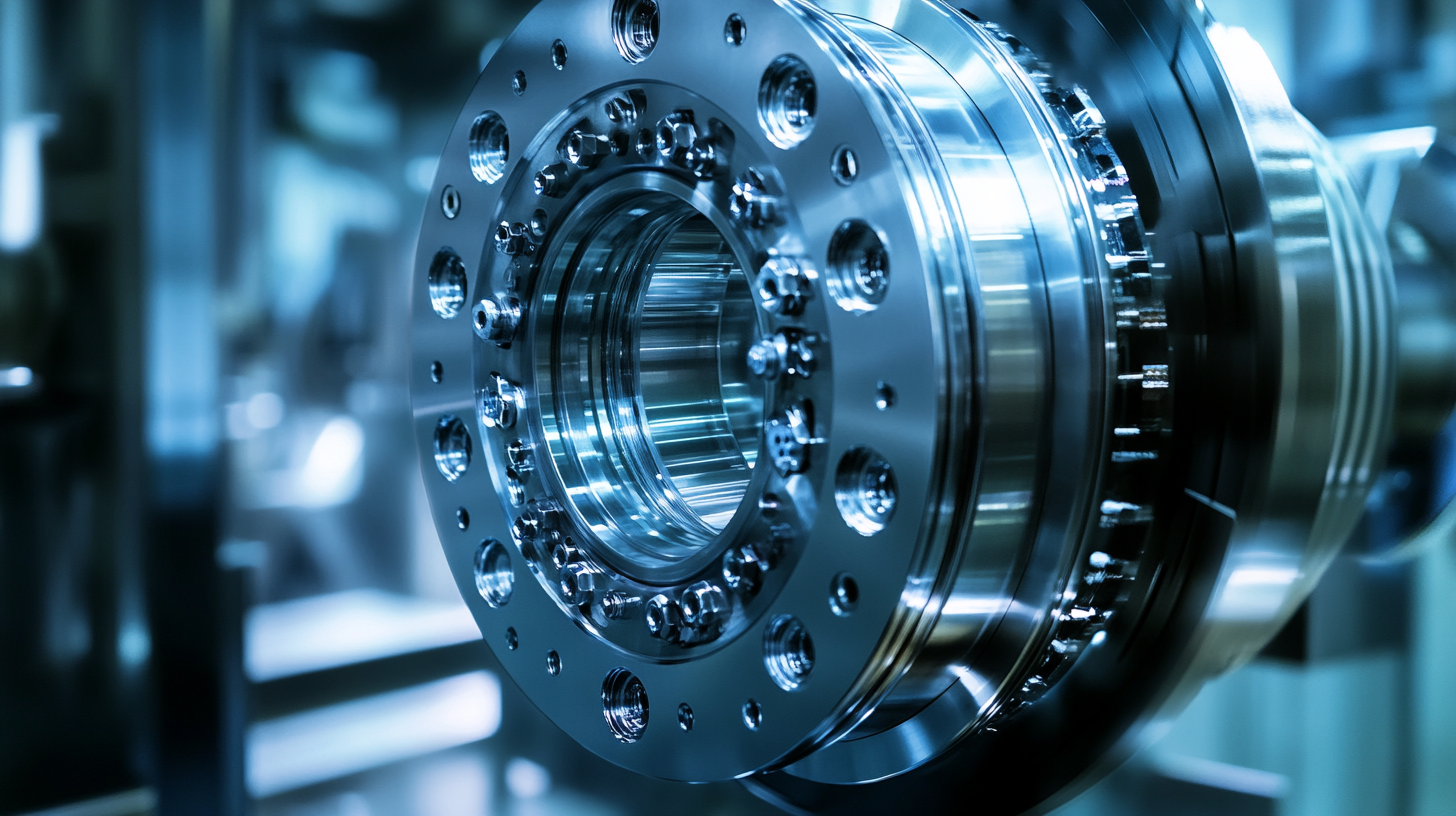

Comparative Analysis: China vs. Global Competitors in Bearing Technology

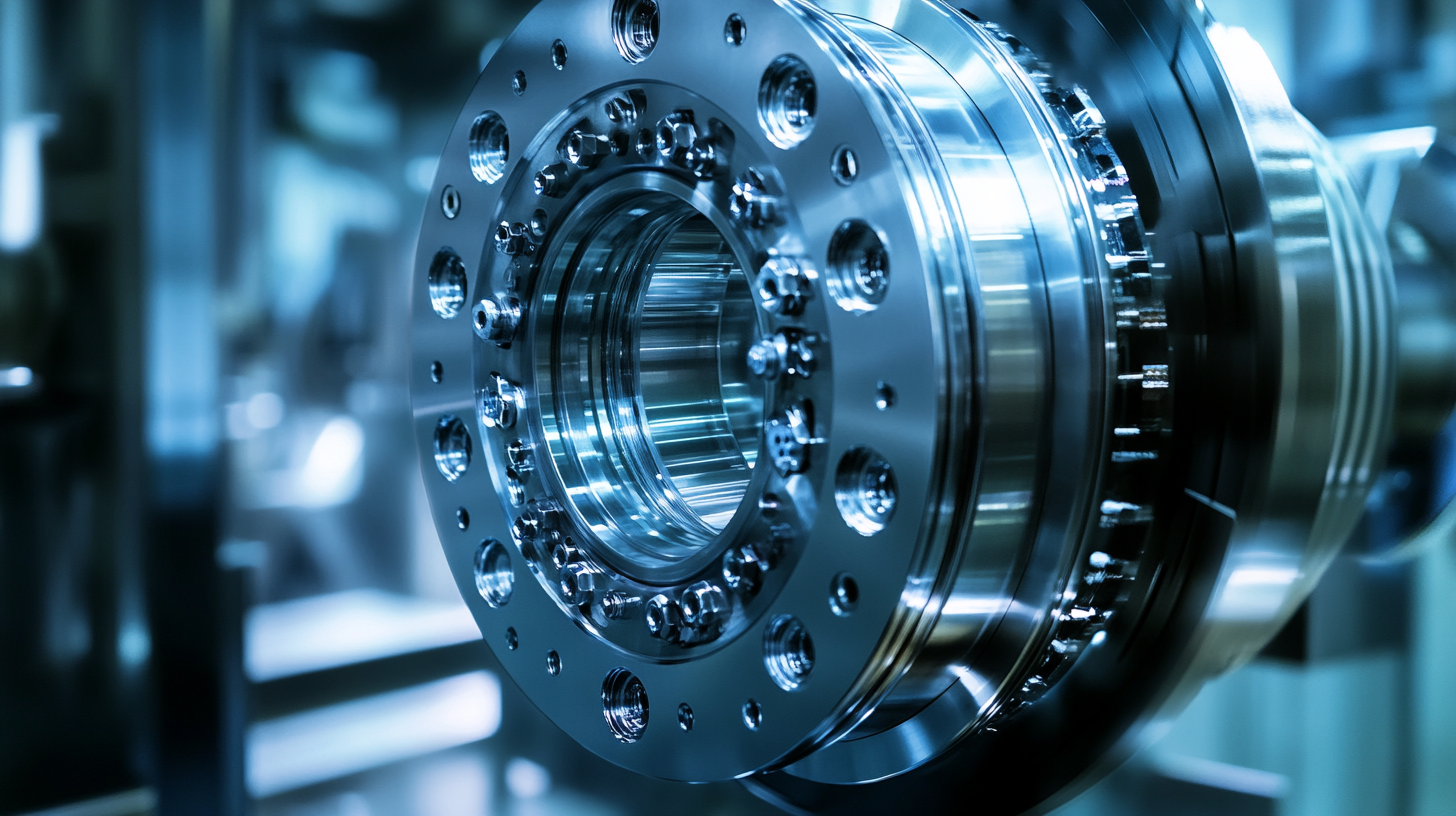

When comparing China’s low noise electric motor bearings with global competitors, it is essential to highlight several key factors that exemplify China's advancements in bearing technology. Over the past decade, Chinese manufacturers have made significant strides in research and development, leveraging modern technology and innovative designs to enhance performance. These advancements include improved material compositions that reduce friction, as well as precision engineering that ensures better alignment and longevity, giving China a competitive edge in noise reduction efficiency.

In contrast to traditional manufacturers in Europe and North America, China's focus on scalability and cost-effectiveness allows for the rapid production of high-quality bearings. While global competitors continue to rely on established practices and premium pricing, Chinese firms are increasingly adopting automated processes and smart manufacturing techniques that drive down costs without compromising quality. This strategic approach not only facilitates domestic demand but also positions Chinese manufacturers as formidable players in the international bearing market, appealing to companies that seek to balance performance with cost. The growing presence of China in this sector signals a shift in global dynamics, highlighting an era where innovation and affordability coexist.

Future Trends in Low Noise Electric Motor Bearings Manufacturing

The future of low noise electric motor bearings manufacturing is intricately linked to the evolving landscape of the electric vehicle (EV) industry. As the demand for electric motors grows, particularly in the realms of new energy vehicles, manufacturing technologies are rapidly advancing. The trend toward wire winding in motors is anticipated to enhance the efficiency and performance of these systems, leading to a significant increase in the penetration of flat wire motors within the market. This transformation is expected to influence the design and functionality of low noise electric motor bearings, driving manufacturers to innovate and adapt.

Key advancements in materials and manufacturing processes are crucial for maintaining a competitive edge in the rapidly expanding automotive sector. As electric drive systems evolve towards integration and high efficiency, the bearings used in these applications must also enhance their performance to meet higher demands for speed and power. Emphasizing low noise characteristics not only improves user experience but also aligns with regulatory trends focusing on sustainability and reduced environmental impact. The future of low noise electric motor bearings will hinge on manufacturers embracing these technological shifts, ultimately unleashing global excellence within the industry.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us