Ultimate Guide to Choosing the Right Ceramic Hybrid Bearings Supplier for Your Needs

In the evolving landscape of industrial applications, the demand for high-performance components has led to a significant increase in the adoption of ceramic hybrid bearings. According to a recent market analysis by ResearchAndMarkets, the global ceramic bearings market is projected to reach USD 5 billion by 2025, highlighting a compound annual growth rate (CAGR) of over 10%. This surge underscores the importance of selecting the right Ceramic Hybrid Bearings Supplier to meet specific operational requirements and performance standards. With their enhanced durability, reduced friction, and resistance to extreme temperatures, ceramic hybrid bearings are becoming the preferred choice across various industries, including automotive, aerospace, and manufacturing. However, the diverse range of suppliers available necessitates careful evaluation to ensure compatibility and reliability, making this guide essential for businesses looking to optimize their supply chain and operational efficiency.

Understanding the Basics of Ceramic Hybrid Bearings and Their Advantages

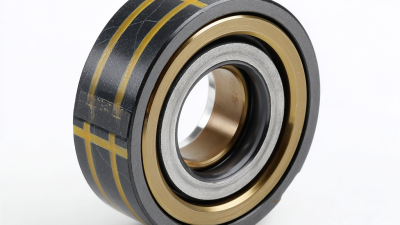

Ceramic hybrid bearings are an innovative solution that combines the best properties of ceramics and traditional materials. These bearings have ceramic balls paired with steel or plastic races, resulting in reduced weight, lower friction, and increased durability. The inherent properties of ceramics, such as their hardness and resistance to corrosion, make hybrid bearings particularly advantageous in applications that require high-speed rotation or exposure to harsh environments. Consequently, industries ranging from aerospace to medical devices are increasingly turning to these advanced bearings to enhance performance and longevity.

In addition to their technical benefits, ceramic hybrid bearings also offer improved thermal performance, which is essential for high- RPM operations where heat dissipation can be a major concern. With reduced heat generation, these bearings can maintain operational efficiency and prolong the lifespan of machinery. When selecting a supplier for these specialized bearings, it’s vital to assess their expertise in both ceramic and hybrid technologies. Understanding the advantages of ceramic hybrid bearings lays a foundation for making informed decisions that will ultimately meet your specific application needs and ensure reliable performance.

Ultimate Guide to Choosing the Right Ceramic Hybrid Bearings Supplier for Your Needs

| Attribute |

Details |

| Material Composition |

Ceramic balls with steel rings |

| Load Capacity |

Higher than traditional bearings |

| Operating Temperature |

Up to 1000 °C in some applications |

| Corrosion Resistance |

Excellent, suitable for harsh environments |

| Friction Coefficient |

Lower than steel bearings |

| Maintenance Requirement |

Reduced maintenance needs |

| Noise Level |

Quieter operation compared to steel bearings |

| Applications |

Aerospace, automotive, medical devices, etc. |

| Typical Lifespan |

Longer lifespan than traditional bearings |

Key Factors to Consider When Selecting a Supplier for Ceramic Hybrid Bearings

When selecting a supplier for ceramic hybrid bearings, several key factors must be taken into consideration to ensure the best performance and reliability for your applications. First and foremost, a supplier’s expertise and experience in the industry is crucial. According to a report by MarketsandMarkets, the global market for ceramic bearings is projected to reach USD 1.5 billion by 2025, indicating rapid growth and a rising demand for reliable suppliers. Choosing a supplier with a proven track record in ceramic hybrid bearings can often translate to better product quality and customer support.

Another important factor to consider is the supplier’s ability to provide customization options. Different applications require different specifications, and a flexible supplier can tailor their offerings to meet these unique needs. Additionally, it is vital to assess the quality assurance processes in place, as stringent testing and certification processes can significantly impact the performance and longevity of ceramic hybrid bearings. A study by the American Bearing Manufacturers Association highlights that 70% of bearing failures are related to material defects; thus, selecting a supplier that prioritizes quality control is essential for ensuring operational success.

Evaluating Quality Standards and Certifications in Ceramic Hybrid Bearings Manufacturing

When selecting a supplier for ceramic hybrid bearings, it is crucial to focus on the quality standards and certifications that reflect the manufacturer’s commitment to excellence. Manufacturers should provide certifications such as ISO 9001, which indicates adherence to international quality management principles. Additionally, look for compliance with industry-specific standards to ensure the bearings meet the required performance and safety benchmarks. High-quality materials and precise manufacturing processes not only enhance product durability but also contribute to improved performance in applications ranging from automotive to industrial automation.

As the market for miniature ball bearings and motor bearings continues to expand, with projected growth across various sectors, the importance of choosing a reliable supplier becomes even more apparent. The rise in revenue for miniature ball bearings is indicative of an increasing demand for quality components that can withstand the rigors of modern machinery. Therefore, prioritizing suppliers who uphold rigorous quality control measures and possess relevant certifications will ultimately lead to better operational efficiency and product longevity in the increasingly competitive landscape of bearing manufacturing.

Analyzing Supply Chain and Delivery Capabilities of Potential Suppliers

When selecting a ceramic hybrid bearings supplier, analyzing their supply chain and delivery capabilities is crucial. A robust supply chain ensures that the supplier can maintain consistent quality and availability of their products. It's essential to evaluate the supplier’s relationships with raw material providers and manufacturing processes to determine whether they can meet your demands without delays. Suppliers with streamlined operations and well-established logistics are more likely to provide timely delivery, which is a key factor in maintaining your project schedules.

Furthermore, consider the supplier’s ability to scale operations based on your needs. Flexibility in production capacity can be a significant advantage, especially during peak demand periods. Ask potential suppliers about their inventory management strategies and how they handle unexpected surges in orders. A dependable supplier will have contingency plans in place to mitigate risks in their supply chain, ensuring that you receive your bearings when you need them most. By assessing these factors, you can make a more informed choice and establish a partnership that supports your operational goals.

Assessing Customer Support and After-Sales Services Offered by Suppliers

When selecting a ceramic hybrid bearings supplier, assessing customer support and after-sales services is crucial. A reliable supplier must offer prompt, knowledgeable assistance to address inquiries and concerns. This includes having a dedicated customer service team that is easily reachable through various channels such as phone, email, or live chat. Positive customer interactions not only enhance trust but also indicate that the supplier values their relationship with clients.

After-sales support is equally important in ensuring that your investment remains protected over time. Look for suppliers that provide warranties, detailed product documentation, and guidance on proper maintenance to prolong the lifespan of the bearings. Additionally, consider whether they offer replacement services or repairs for faulty products. A robust after-sales service demonstrates the supplier's commitment to customer satisfaction and can significantly impact the overall experience of using their products. Prioritizing these aspects will lead you to a supplier that not only meets your immediate needs but also supports you in the long run.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us