Ultimate Guide to Navigating North American Bearing Certification Requirements

In the dynamic landscape of manufacturing and engineering, achieving compliance with

North American Bearing Certification

standards is not just a regulatory requirement, but a crucial factor for

market competitiveness and product reliability.

According to industry reports, the bearing market in North America is projected to grow significantly,

with a compound annual growth rate (CAGR)

of over 4% by 2025, driven largely by the automotive and renewable energy sectors.

As global supply chains become increasingly complex, understanding and navigating the

certification requirements

is essential for manufacturers looking to ensure their products meet stringent quality

and performance benchmarks. This ultimate guide will illuminate the critical aspects of

North American Bearing Certification, equipping

industry professionals with the knowledge to streamline compliance processes, enhance

product quality, and capitalize on market opportunities.

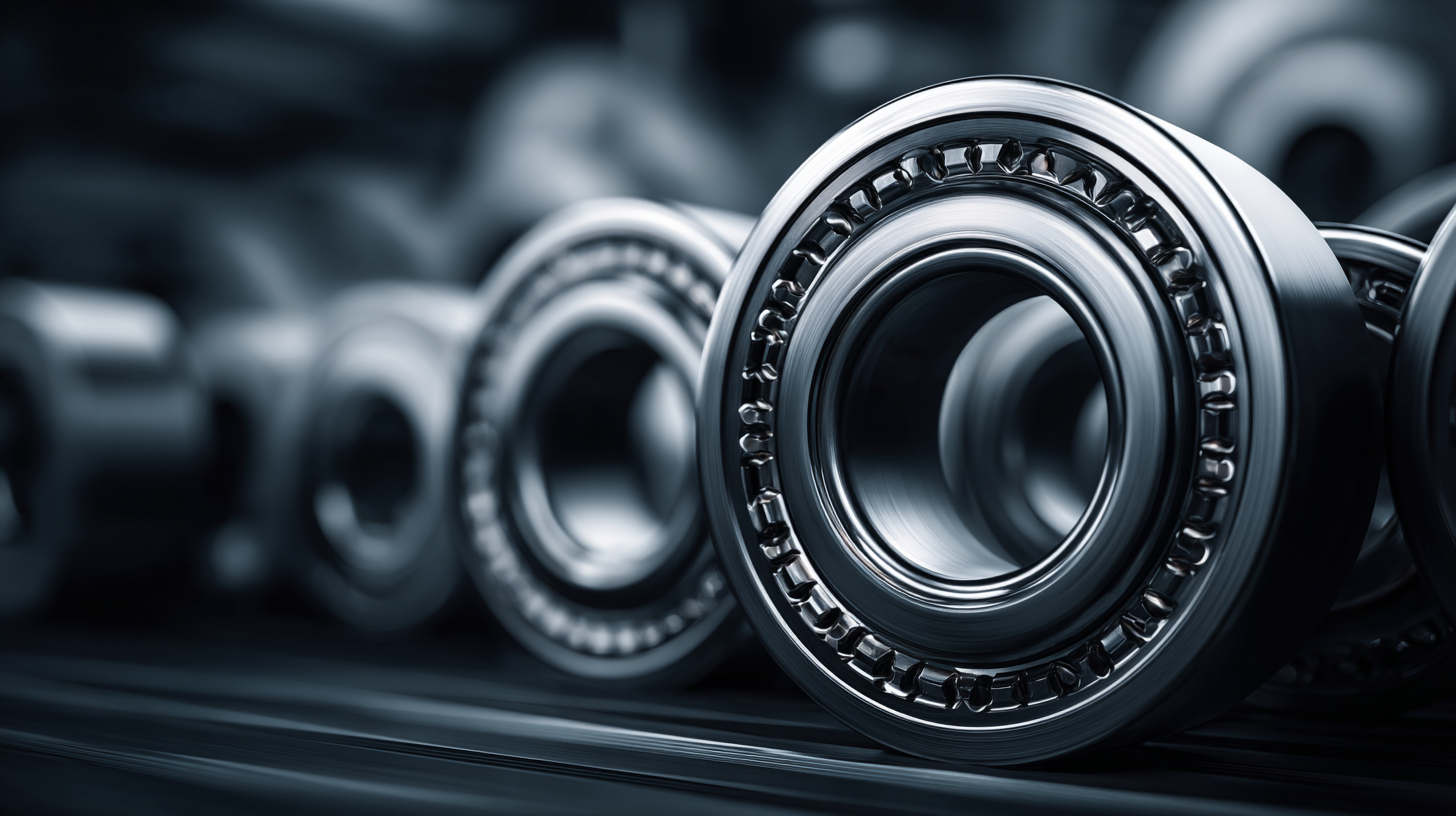

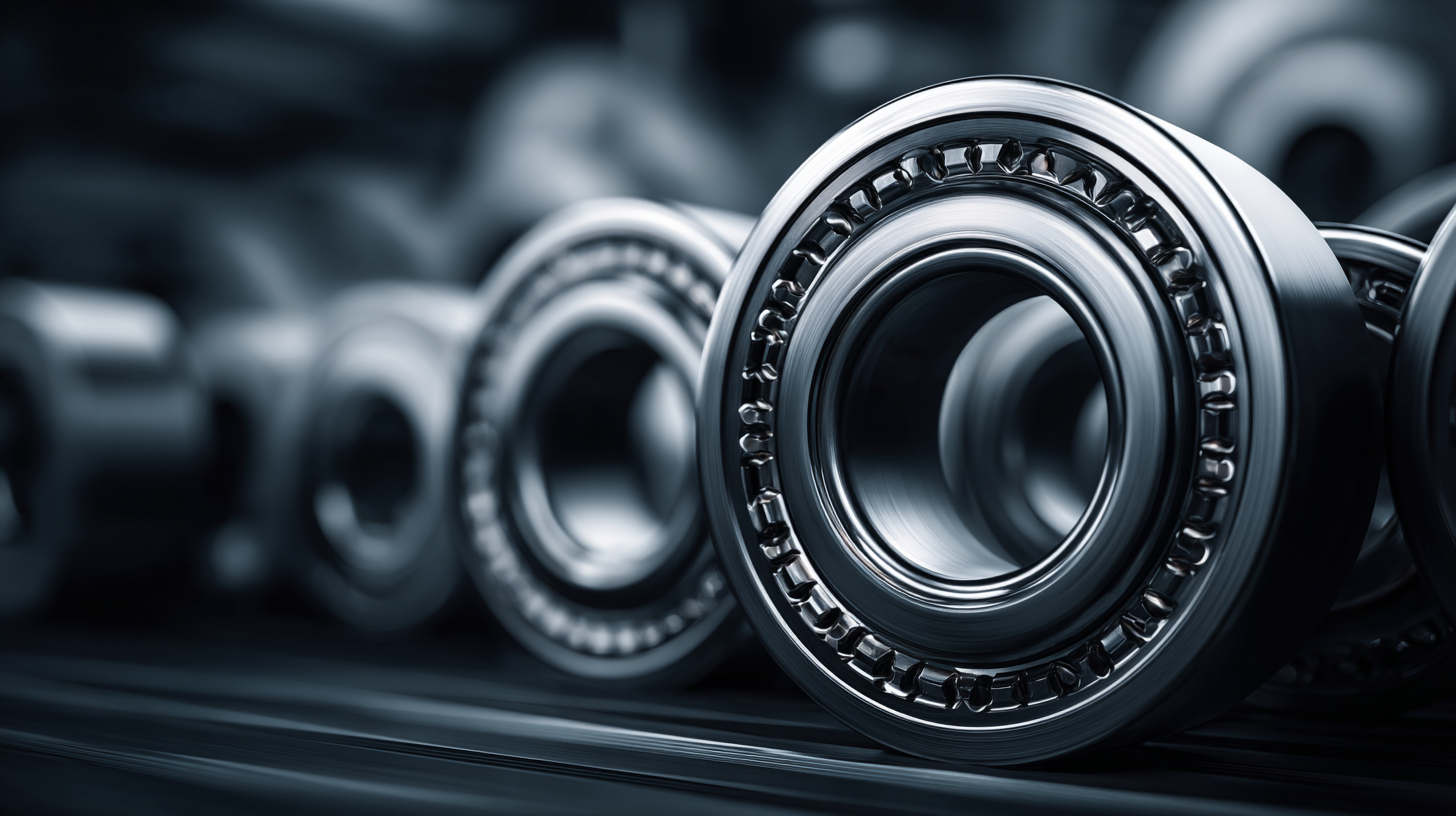

Understanding the Importance of Bearing Certification in North America

Bearing certification in North America plays a crucial role in ensuring product quality, safety, and performance. As industries increasingly rely on bearings for critical applications, certification serves as a benchmark that signifies compliance with established standards. It provides manufacturers and consumers alike with the assurance that the products they are using meet rigorous performance criteria, thus reducing the risk of failure and enhancing operational efficiency.

Understanding the importance of bearing certification extends beyond mere compliance; it highlights the commitment to excellence in manufacturing processes. Certified bearings can help organizations maintain reliability in their operations while fostering trust with clients. Additionally, certification often facilitates easier access to the North American market, as many industries require evidence of compliance before accepting products. As a result, investing in bearing certification not only enhances product credibility but also positions companies favorably in a competitive landscape.

Key Certification Standards and Regulations for Bearings in North America

Navigating the certification requirements for bearings in North America is a complex process that involves understanding several key standards and regulations. At the forefront are the

American National Standards Institute (ANSI) and the

American Society for Testing and Materials (ASTM), which provide guidelines that ensure performance and safety across various applications.

Compliance with ANSI standards typically involves rigorous testing procedures that evaluate the mechanical properties and durability of bearing products. ASTM standards, on the other hand, focus on the material specifications and testing methodologies, ensuring that manufacturers meet the necessary quality benchmarks.

In addition to ANSI and ASTM, companies may also need to consider certification from the

International Organization for Standardization (ISO), which has established globally recognized criteria that can affect trade in North America. ISO certification not only enhances product credibility but also aligns manufacturers with international best practices.

Furthermore, industry-specific regulations, such as those from the automotive or aerospace sectors, may impose stricter requirements, necessitating thorough knowledge of both federal and state regulations.

Understanding these certifying bodies and their requirements is crucial for manufacturers aiming to succeed in the competitive North American market.

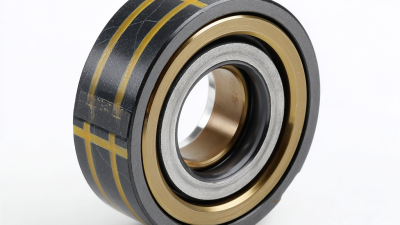

Step-by-Step Process for Obtaining Bearing Certification

Obtaining bearing certification in North America involves a clear step-by-step process essential for ensuring product quality and compliance with industry standards. First, manufacturers must familiarize themselves with the relevant guidelines set forth by organizations like ANSI and ISO. These standards not only outline safety and performance metrics but also facilitate consistency in manufacturing practices.

According to a 2022 report by the National Association of Manufacturers, 75% of companies found that adherence to certification requirements enhanced customer trust and improved market competitiveness.

One of the critical steps involves selecting a recognized certification body to conduct the evaluations. Tips for this include ensuring that the body is accredited and has a solid reputation within the industry. Engaging with a certification agency early in the product development process can streamline the certification timeline, which, as per a 2023 industry survey, can take anywhere from three months to a year, depending on the complexity of the product.

Furthermore, proper documentation and testing protocols are vital. Regular internal audits can help identify areas for improvement before the official certification process begins. It is advisable to prepare comprehensive technical documentation, reflecting the design, manufacturing processes, and quality controls employed. As highlighted by the Bearing Industry Manufacturers Association, organizations that invest in robust documentation practices are 30% more likely to clear the certification process on their first attempt.

Common Challenges and Solutions in Navigating Certification Requirements

Navigating certification requirements for bearings in North America can be a daunting task, as companies often face various challenges. One common obstacle is the complex landscape of regulations, which can differ significantly between states and provinces. Manufacturers must stay informed about the specific standards set by organizations like the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO). This can lead to confusion and misalignment, particularly for businesses operating in multiple jurisdictions.

To address these challenges, companies can adopt a proactive approach by leveraging resources such as industry associations and regulatory consultants. Joining relevant trade organizations can provide essential updates on certification processes and best practices, while professional consultants can offer tailored advice for navigating specific requirements. Additionally, investing in training for staff on compliance and certification can streamline the process, ensuring everyone involved understands the requirements and timelines associated with product certification. This knowledge not only aids in compliance but can also lead to more efficient operations overall, helping manufacturers to avoid costly delays and rework.

Ultimate Guide to Navigating North American Bearing Certification Requirements

| Certification Type |

Issuing Organization |

Common Challenges |

Possible Solutions |

| ISO 9001 |

International Organization for Standardization |

Document variations and client compliance |

Use standardized templates and regular audits |

| ASTM F3053 |

ASTM International |

Inconsistent testing procedures |

Train personnel and implement clear protocols |

| UL 60825 |

Underwriters Laboratories |

Complex documentation requirements |

Invest in documentation management software |

| CE Marking |

European Commission |

Misunderstanding of compliance scope |

Consult with compliance experts |

| SAE J1159 |

Society of Automotive Engineers |

Lack of industry knowledge |

Ongoing training and workshops |

Future Trends in Bearing Certification and Industry Compliance in North America

As the bearing industry in North America continues to evolve, staying ahead of future trends in certification and compliance is crucial for manufacturers and suppliers. One significant trend is the increasing emphasis on sustainability and environmental impact. Regulatory bodies are beginning to incorporate green standards into certification processes, urging manufacturers to adopt eco-friendly materials and practices. This shift not only helps in contributing to a healthier planet but also opens up new markets, as consumers and industries become more environmentally conscious.

Another noteworthy trend is the advancement of technology in the certification process. The integration of digital tools and data analytics is transforming how inspections and testing are carried out. With the advent of Industry 4.0, real-time monitoring and predictive maintenance using IoT devices are becoming common. This shift enhances the reliability of bearing products and ensures compliance with stringent certification requirements. As the industry moves forward, staying informed and adapting to these trends will be key for companies aspiring to maintain their competitive edge in North America’s bearing market.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us