Transform Your Operations: Heavy Machinery Bearing Replacement Solutions from a Leading Chinese Manufacturer

In today's fast-paced industrial landscape, the efficiency and reliability of heavy machinery are paramount to staying competitive. When it comes to ensuring optimal performance, one critical component that often warrants attention is the bearing system. The "Heavy Machinery Bearing Replacement Guide" serves as an essential resource for operators and maintenance teams tasked with the upkeep of vital equipment. This blog explores innovative bearing replacement solutions from a leading Chinese manufacturer, renowned for their quality and durability. By leveraging the latest technology and expert craftsmanship, these solutions not only enhance the lifespan of machinery but also minimize downtime and operational losses. Join us as we delve into the importance of proper bearing replacement in heavy machinery and uncover how advanced solutions can transform your operations for the better.

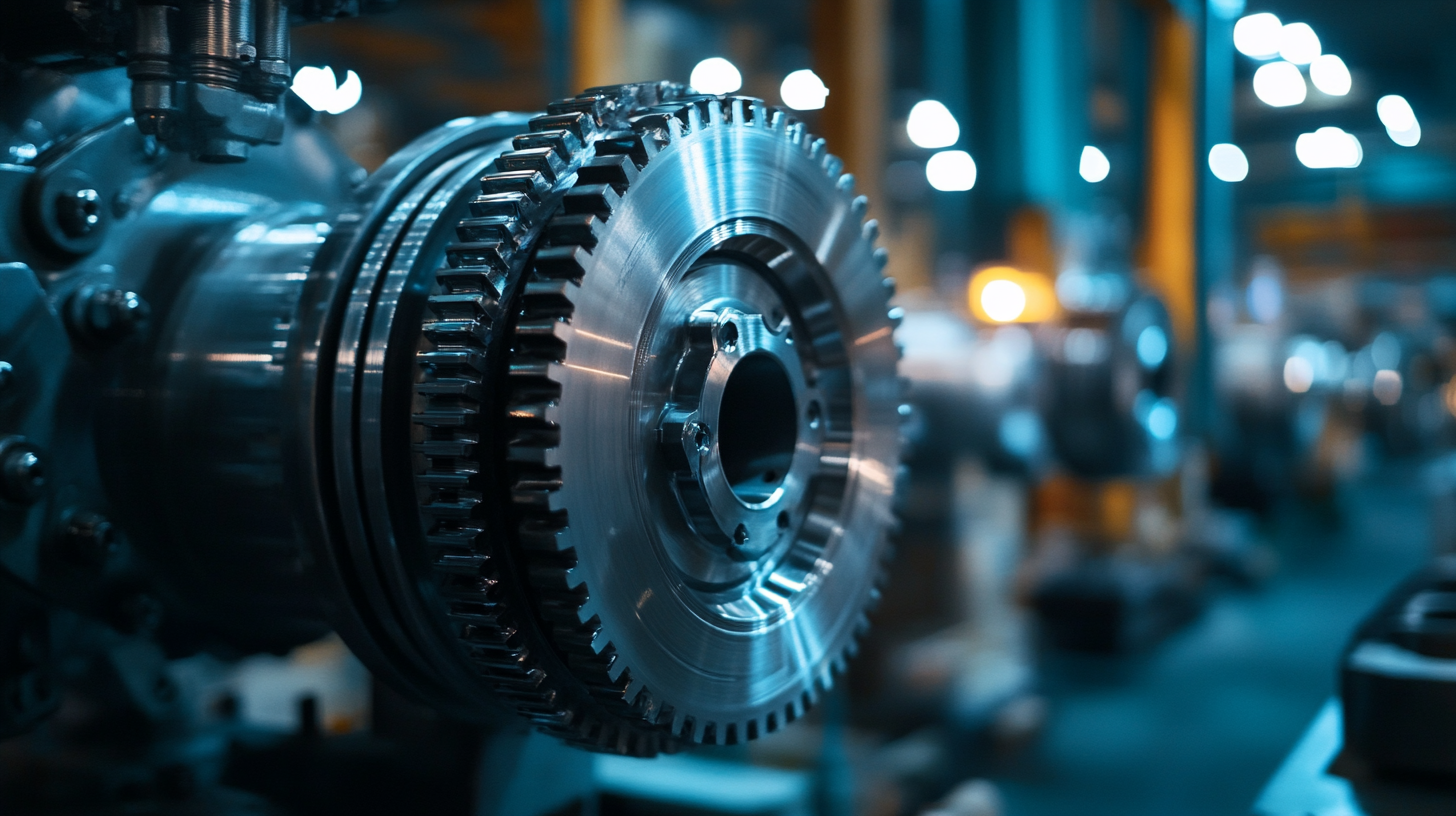

Understanding the Importance of Bearing Replacement in Heavy Machinery Operations

In heavy machinery operations, the significance of bearing replacement cannot be overstated. Bearings play a crucial role in ensuring smooth movement and reducing friction between moving parts. Over time, wear and tear can lead to compromised performance, resulting in increased downtime and potentially costly repairs. Regularly replacing bearings allows for optimal functionality, extending the life of the machinery and enhancing overall productivity.

As operations evolve, the demands on heavy machinery also increase, making it imperative for operators to prioritize maintenance routines that include bearing inspections and timely replacements. Identifying signs of bearing failure, such as unusual noises or vibrations, can help prevent catastrophic breakdowns. Partnering with a leading Chinese manufacturer known for quality bearing solutions ensures that operators have access to durable products designed to withstand the rigors of heavy-duty applications. This proactive approach not only minimizes risks but also maximizes the efficiency and reliability of machinery in demanding environments.

Key Benefits of Choosing a Leading Chinese Manufacturer for Bearings

When it comes to heavy machinery operations, the bearings you choose can profoundly impact efficiency and longevity. Opting for a leading Chinese manufacturer provides several key benefits that stand out in the industry. According to a report by MarketsandMarkets, the global bearings market is expected to reach $146 billion by 2026, increasing the demand for high-quality and reliable bearing solutions. Chinese manufacturers have been increasingly recognized for their innovative designs and advanced manufacturing techniques, allowing them to compete on a global scale.

One of the most significant advantages of partnering with a top Chinese manufacturer is cost-effectiveness. Research from the International Organization for Standardization (ISO) indicates that sourcing from China can reduce production costs by up to 30% while maintaining quality standards. Additionally, these manufacturers often utilize state-of-the-art technology, including automated processes that enhance precision and reduce error margins, which is crucial for the heavy machinery sector.

Furthermore, leading Chinese manufacturers are committed to sustainable practices and adherence to international standards. A report from the World Economic Forum emphasizes that firms adopting environmentally responsible manufacturing processes can significantly cut operational costs by as much as 30%. By choosing a reputable Chinese bearing manufacturer, companies not only ensure robust performance in their heavy machinery but also contribute to a more sustainable future in industrial manufacturing.

Factors to Consider When Selecting Replacement Bearings for Heavy Equipment

When it comes to heavy equipment maintenance, selecting the right replacement bearings is crucial for ensuring optimal performance and longevity. There are several key factors to consider when making this decision. First and foremost, the load and operational conditions of your machinery must be assessed. Different applications may experience varying degrees of stress and temperature, which can significantly affect bearing selection. Heavy machinery often operates in harsh environments, so bearings must be durable enough to withstand elements like dust, moisture, and extreme temperatures.

Another important consideration is the compatibility of the replacement bearings with the existing machinery. This includes checking the size, materials, and design specifications to ensure a proper fit and function. Additionally, it’s beneficial to choose bearings from a reliable manufacturer that offers quality assurance and extensive product support. A leading Chinese manufacturer can provide a range of options tailored to different types of heavy equipment, ensuring that you make a wise investment that enhances operational efficiency. By carefully evaluating these factors, you can transform your operations and prolong the lifespan of your machinery.

Innovative Bearing Technologies Revolutionizing Heavy Machinery Performance

In the dynamic world of heavy machinery, maintaining peak performance is essential for productivity and efficiency. Innovative bearing technologies have become a game-changer, significantly enhancing the operational capabilities of machinery. By integrating advanced materials and precision engineering, these bearings offer improved durability and reliability, reducing unplanned downtime and maintenance costs. The latest designs cater to the unique demands of heavy-duty applications, ensuring that machinery can withstand extreme conditions and heavy loads with ease.

Chinese manufacturers are at the forefront of this revolution, investing heavily in research and development to create state-of-the-art bearing solutions. Their commitment to quality and innovation leads to the development of bearings that not only improve performance but also extend the lifespan of machinery components. Features such as enhanced lubrication systems, corrosion resistance, and self-aligning capabilities are now common, giving operators the confidence they need to maximize their equipment's potential. As the construction and mining industries evolve, these cutting-edge bearing technologies will continue to play a crucial role in pushing the boundaries of heavy machinery performance.

Cost-Effectiveness of Timely Bearing Replacement for Operational Efficiency

Timely bearing replacement is crucial for maintaining the operational efficiency of heavy machinery. In a competitive industrial environment, any downtime can result in significant financial losses. The cost-effectiveness of regularly replacing bearings cannot be overstated; it not only prolongs the lifespan of machinery but also enhances overall performance. By strategically scheduling maintenance, companies can avoid unexpected breakdowns, leading to smoother operations and reduced repair costs.

To maximize the benefits of bearing replacement, it is essential to implement effective monitoring strategies. Vibration analysis is a reliable method for assessing bearing health and detecting potential failures early. By regularly analyzing vibration signals, operators can identify signs of wear and take proactive measures before issues escalate. This can save both time and resources in the long run.

Additionally, working with a trusted manufacturer can ensure that high-quality bearings are utilized in machinery. Quality bearings are designed to withstand the rigors of heavy operation, further minimizing the risk of failure. When selecting a replacement bearing, consider factors such as load capacity, material durability, and manufacturer reputation to ensure optimal performance and extended equipment life.

Cost-Effectiveness of Timely Bearing Replacement for Operational Efficiency

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us