High-Quality Heavy-Duty Bearings: Your Trusted Chinese Manufacturing Partner in Global Mining Solutions

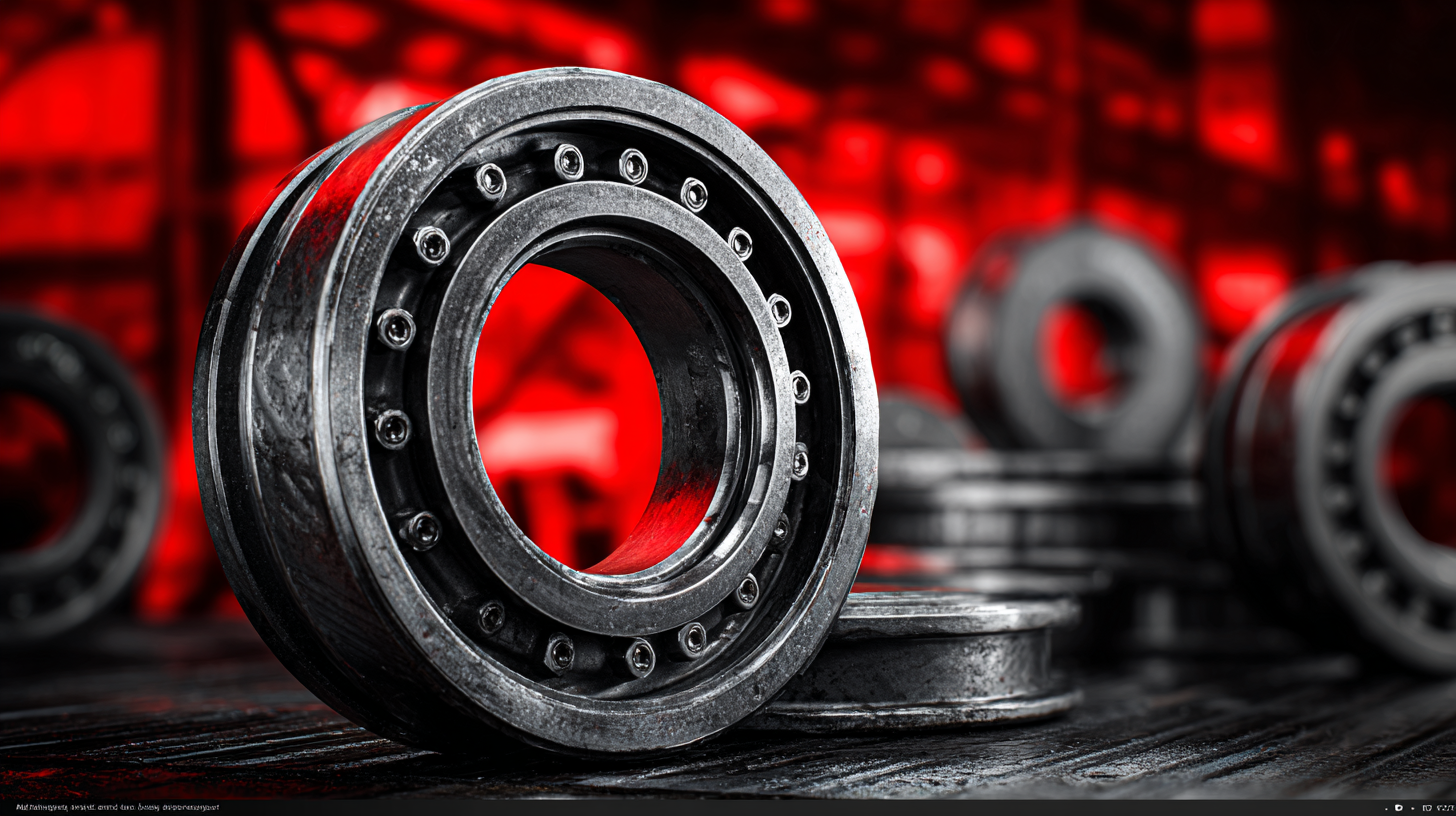

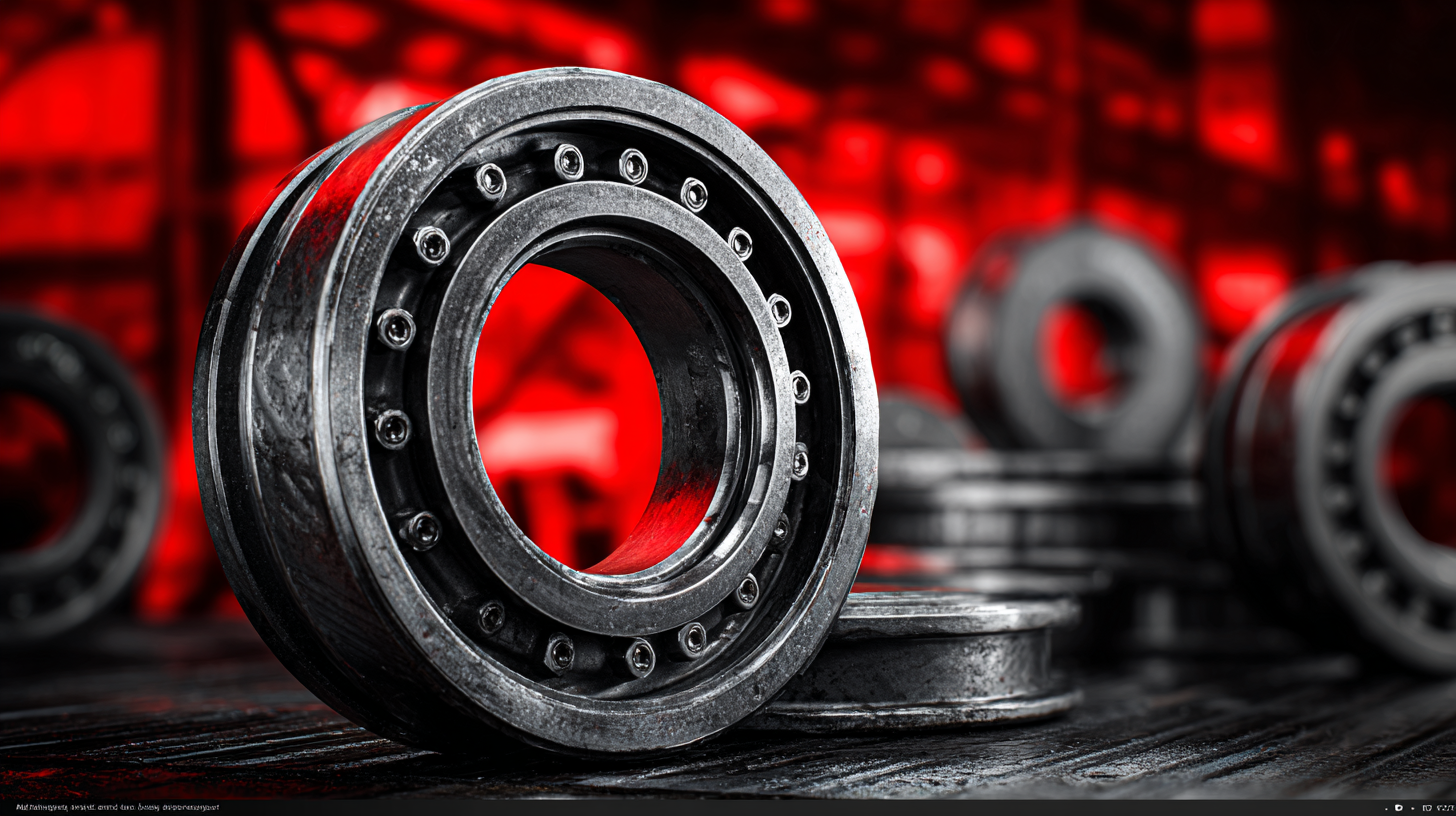

In the rapidly evolving landscape of global mining solutions, high-quality heavy-duty bearings play a pivotal role in enhancing operational efficiency and reliability. Mining Machinery Heavy-Duty Bearings are critical components that withstand the extreme conditions of the industry, including heavy loads, dirt, and harsh temperatures.

According to a recent report by Allied Market Research, the global market for heavy-duty bearings is projected to reach $24 billion by 2027, driven by the increasing demand for advanced machinery in mining operations. As mining activities intensify and equipment becomes more sophisticated, the need for durable and efficient bearings becomes paramount. This underscores the importance of partnering with trusted manufacturers, especially in China, known for their extensive experience and capabilities in delivering high-performance bearing solutions tailored for the mining sector.

The Importance of Heavy-Duty Bearings in Modern Mining Operations

In the modern mining industry, the significance of heavy-duty bearings cannot be overstated. These specialized components are critical to ensuring the smooth operation and longevity of mining machinery. In challenging environments, where equipment faces massive loads, harsh weather conditions, and abrasive materials, heavy-duty bearings provide the necessary reliability and performance. By reducing friction and wear, they enhance the efficiency of machines, leading to increased productivity and reduced downtime.

Furthermore, the choice of high-quality bearings can dramatically impact maintenance costs and operational efficiency. Investing in superior heavy-duty bearings not only boosts the overall performance of mining equipment but also minimizes the risk of unexpected failures. As mining operations strive for sustainability and efficiency, a trusted partner in manufacturing heavy-duty bearings becomes essential. By leveraging advanced technology and materials, manufacturers can deliver products that meet the rigorous demands of modern mining, ultimately supporting the industry's growth and success on a global scale.

High-Quality Heavy-Duty Bearings in Modern Mining Operations

| Bearing Type |

Load Capacity (kN) |

Speed Rating (RPM) |

Material |

Application |

| Spherical Roller Bearing |

1500 |

700 |

Chrome Steel |

Excavators |

| Tapered Roller Bearing |

2000 |

500 |

Alloy Steel |

Loaders |

| Deep Groove Ball Bearing |

800 |

1200 |

Carbon Steel |

Conveyor Systems |

| Angular Contact Bearing |

1200 |

900 |

Stainless Steel |

Ball Mills |

| Cylindrical Roller Bearing |

1350 |

600 |

Bronze |

Drilling Rigs |

Innovations in Manufacturing: Ensuring Quality and Durability for Bearings

In the global mining industry, the reliability and performance of equipment are paramount, and this is where innovations in bearing manufacturing play a crucial role. Recent studies indicate that high-quality heavy-duty bearings significantly reduce machinery downtime by up to 30%, enhancing overall operational efficiency. As the demand for durable bearings increases, manufacturers are turning to advanced technologies and materials to meet these challenges. For instance, the implementation of precision engineering and fatigue-resistant materials has shown a marked improvement in the lifespan of bearings, with some products achieving over 150% longer service life than conventional options.

Furthermore, advancements in manufacturing techniques, such as additive manufacturing and enhanced quality control processes, are revolutionizing the industry. According to a report by MarketsandMarkets, the global bearings market is projected to grow from USD 90 billion in 2021 to USD 128 billion by 2026, driven largely by the mining sector. This growth underscores the importance of dependable bearings, as the cost of equipment failure can reach up to USD 1 million per incident. By investing in innovative manufacturing practices, Chinese manufacturers are positioning themselves as trusted partners in providing robust solutions that meet the intricate demands of global mining operations.

Choosing the Right Bearing Supplier: Key Factors for Mining Companies

When it comes to mining operations, selecting the right bearing supplier is crucial to ensure reliable performance and longevity of equipment. Mining companies should prioritize suppliers who offer high-quality heavy-duty bearings tailored to withstand harsh conditions. Key factors to consider include the manufacturer's reputation, product range, and the ability to customize solutions according to specific mining needs. A trusted supplier not only provides durable products but also supports clients with expert advice on maintenance and best practices.

Additionally, companies should evaluate the supplier’s production capabilities and quality control processes. Understanding the materials and technologies employed in bearing manufacturing can help mining operators make informed decisions. Look for suppliers that utilize advanced engineering techniques, ensuring their bearings can handle extreme loads and environmental challenges. Building a partnership with a reliable Chinese manufacturer can enhance operational efficiency and minimize downtime, ultimately driving increased productivity in mining operations.

Sustainability in Bearings Production: A Commitment to Eco-Friendly Practices

Sustainability has become a vital focus in the manufacturing sector, especially in the production of heavy-duty bearings essential for global mining solutions. With the mining industry contributing to approximately 4.5% of global greenhouse gas emissions, adopting eco-friendly practices in bearing manufacturing is crucial. Leading manufacturers are increasingly utilizing recycled materials and energy-efficient processes, significantly reducing their carbon footprints. Reports indicate that implementing sustainable production methods can decrease energy consumption by up to 50%, showcasing the potential for substantial environmental benefits.

When choosing bearings for mining applications, it’s important to consider manufacturers that prioritize sustainability. Look for certifications such as ISO 14001, which indicates a commitment to effective environmental management systems. Furthermore, utilizing bearings designed for durability can extend service life by over 30%, reducing the frequency of replacements and conserving resources.

Tip: Opt for bearings designed with low-friction materials and advanced lubricants, which not only enhance performance but also contribute to energy savings in mining operations. By supporting manufacturers committed to eco-friendly practices, you contribute to a more sustainable mining industry while ensuring reliable equipment performance.

Future Trends in Mining Equipment: Adapting Bearings for Emerging Technologies

As the mining industry evolves, so too must the equipment that powers it. Emerging technologies such as automation, data analytics, and artificial intelligence are reshaping operational practices, prompting the need for adaptability in heavy-duty bearings. According to a report by MarketsandMarkets, the global mining equipment market is projected to grow from USD 98 billion in 2023 to USD 135 billion by 2028, emphasizing the urgency for innovative bearing solutions that can withstand greater loads and operational stresses.

To keep pace with these advancements, manufacturers are increasingly focusing on materials and designs that enhance durability and performance. High-quality bearings made from advanced composites or through innovative manufacturing processes can significantly improve the reliability of mining equipment. Tips for mining companies include regular maintenance checks and investing in state-of-the-art bearing technologies to ensure optimal performance in challenging environments.

Furthermore, the integration of IoT in mining operations raises the bar for bearing performance. As more devices become interconnected, the demand for bearings that can facilitate real-time monitoring of equipment health is growing. This shift could potentially reduce downtime and maintenance costs, with a study indicating that predictive maintenance can save businesses up to 40% in maintenance costs. Embracing these trends is essential for staying competitive in a rapidly changing market.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us