What are High-Speed Bearings Custom Services and Their Benefits?

High-Speed Bearings Custom Service offers tailored solutions for various industries. These services are crucial for enhancing equipment efficiency. High-speed bearings serve applications ranging from aerospace to automotive.

The customization process allows companies to meet specific operational needs. This includes size, materials, and load capacities. However, not all services achieve the desired results. Sometimes, a standard approach may suffice, yet customization provides unique advantages.

Choosing the right custom service is critical. Companies often overlook potential challenges in manufacturing. Costs and timeline issues can arise unexpectedly. Reflecting on these aspects can lead to better decisions. High-Speed Bearings Custom Service can unlock performance benefits, but careful consideration is necessary.

What are High-Speed Bearings and Their Applications in Industry?

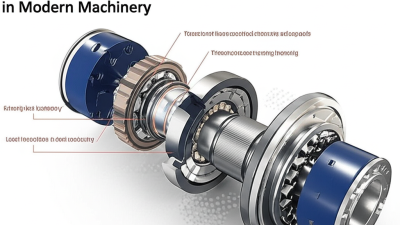

High-speed bearings are essential components in various industries. They are designed to allow smooth rotation at high speeds, which reduces friction and heat. This efficiency can significantly enhance the performance of machinery. In manufacturing and automotive sectors, these bearings improve the reliability of equipment. They are key in applications like electric motors, turbines, and conveyor systems.

Many industries rely on high-speed bearings to increase productivity. These bearings not only reduce downtime but also extend the lifespan of equipment. For instance, in an assembly line, quick and efficient movement is crucial. Even a minor malfunction can lead to considerable losses. Yet, choosing the right bearing can be challenging. Different designs and materials offer varying benefits. It can be hard to balance speed with load-carrying capacity.

In addition, customization is often necessary. Every application has unique demands. High-speed bearings can be tailored to fit specific needs. However, this process requires careful planning and testing. Some modifications may initially seem beneficial but can lead to unforeseen issues. It's essential to thoroughly evaluate performance in real-world conditions. Without proper analysis, it might result in underwhelming outcomes that go against expectations.

The Importance of Custom Services in High-Speed Bearing Production

Custom services in high-speed bearing production hold significant importance. Each application is unique, requiring specific features for optimal performance. By tailoring solutions, manufacturers can meet diverse needs. This ensures that bearings function seamlessly within their intended environments.

The right customizations can greatly enhance efficiency. Adjustments might include size alterations or material selections. However, the process of customization requires close collaboration. Miscommunication can lead to mistakes, so clarity is essential. It’s a delicate balance between creativity and precision. Each design must be carefully vetted to avoid issues later.

Moreover, custom services can help in improving durability. The right specifications can reduce wear and tear. Yet, this requires a strong understanding of operational conditions. Some companies may rush to production. This could result in a product that does not perform well. Constant feedback loops can refine designs further, but they need commitment. Overall, the journey of customization is complex, filled with both challenges and opportunities.

Key Benefits of High-Speed Bearings for Enhanced Performance

High-speed bearings play a crucial role in modern machinery. They are designed to reduce friction and support faster rotational speeds. This can lead to improved efficiency in various applications, from automotive engines to industrial machines. High-speed bearings enhance performance significantly. They ensure smoother operation and minimize wear over time.

One major benefit is increased reliability. With high-speed bearings, systems can run longer without failure. This can lead to lower maintenance costs and less downtime. However, it’s vital to consider the proper alignment and lubrication. Without these, even the best bearings can underperform. Misalignment can cause uneven wear, leading to premature failure. Proper care is essential.

Temperature management is another key aspect. High-speed operations generate heat, potentially damaging components. Quality bearings can handle higher temperatures better. Users must also monitor for overheating signs. Regular checks can help catch issues early. This attention to detail is what truly enhances performance.

Industry Standards and Quality Control in High-Speed Bearing Manufacturing

High-speed bearings play a crucial role in various industrial applications. Their manufacturing adheres to strict industry standards. Quality control is paramount throughout the production process. Each component must meet specific tolerances to ensure optimal performance.

Regular inspections check for defects and inconsistencies. This involves assessing materials and craftsmanship. An essential aspect of quality control is testing bearings under simulated operational conditions. This helps identify potential failures before they occur in real-world applications.

Tips: Always verify that manufacturers comply with industry standards. Ask for certificates and testing results. Be aware that even minor flaws can lead to significant operational issues. Choose suppliers who prioritize transparency in their processes.

Customization services for high-speed bearings can also influence quality. Tailored designs may require additional testing. This customization can enhance efficiency, but it can complicate quality assurance. Understanding these factors is essential for manufacturers and engineers.

What are High-Speed Bearings Custom Services and Their Benefits? - Industry Standards and Quality Control in High-Speed Bearing Manufacturing

| Service Type |

Description |

Benefits |

Industry Standards |

Quality Control Measures |

| Customization |

Tailoring bearings to specific application needs |

Improved performance and longevity |

ISO 9001 |

Regular inspections and testing |

| Material Selection |

Choosing optimal materials for specific environments |

Enhanced durability and resistance to wear |

ASTM Standards |

Material testing and certification |

| Precision Engineering |

High-accuracy machining processes |

Reduced operational friction and noise |

ISO/TS 16949 |

Dimensional and performance validation |

| Lubrication Solutions |

Providing tailored lubrication systems |

Optimization of bearing life and efficiency |

ISO 15380 |

Lubricant testing and analysis |

| After-Sales Support |

Providing ongoing maintenance and support |

Increased customer satisfaction and reliability |

Customer feedback standards |

Continuous improvement protocols |

Economic Impact: Cost Savings with Customized High-Speed Bearings

Customized high-speed bearings are essential for enhancing operational efficiency in various industries. Tailoring these components can lead to substantial cost savings. According to a recent industry report, companies that implement custom bearing solutions experience up to a 25% reduction in production downtime. This reduction translates to significant economic gains, allowing for the reallocation of resources where they are most needed.

Custom bearings can improve energy efficiency as well. The same report indicates that optimized bearing designs can decrease energy consumption by up to 15%. This reduction not only lowers utility costs but also minimizes environmental impact. However, many companies overlook these benefits. They stick to standard solutions, limiting performance. As industries advance, the need for tailored solutions becomes increasingly clear.

Another striking detail is the lifespan of customized bearings. Reports show that they can last 30% longer than generic options under similar conditions. Long-term benefits often outweigh initial investment costs. Nevertheless, some businesses hesitate due to upfront expenses. They may fail to recognize the value of long-term savings. Embracing custom high-speed bearings can offer undeniable advantages in both performance and cost efficiency.

Economic Impact of Customized High-Speed Bearings

This bar chart illustrates the cost savings associated with different levels of customization for high-speed bearings. As the level of customization increases, the potential cost savings for businesses can significantly rise, highlighting the economic advantages of tailored solutions.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us