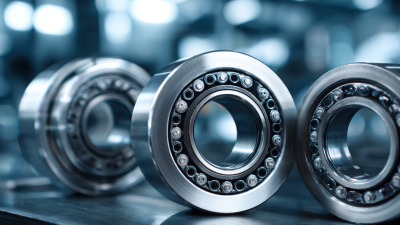

Understanding the Importance of CE Certification for Bearings in the EU Market

In today's competitive marketplace, achieving compliance with industry standards is crucial for manufacturers, especially in the European Union. Among the various certifications available, CE certification stands out as an essential requirement for products entering the EU market.

Specifically, CE Certified Bearings for EU Market play a pivotal role in ensuring that these components meet the necessary safety, health, and environmental protection regulations set forth by the European Union. The significance of obtaining CE certification extends beyond mere paperwork; it serves as a mark of quality and reliability that can substantially enhance a product's marketability.

Specifically, CE Certified Bearings for EU Market play a pivotal role in ensuring that these components meet the necessary safety, health, and environmental protection regulations set forth by the European Union. The significance of obtaining CE certification extends beyond mere paperwork; it serves as a mark of quality and reliability that can substantially enhance a product's marketability.

This introduction aims to delve into the intricate relationship between CE certification and the bearing industry, emphasizing the implications of compliance for businesses looking to thrive in the EU market. Understanding this critical certification process not only helps manufacturers to mitigate risks but also promotes consumer trust in their products, ultimately shaping the future of the bearing market in Europe.

How CE Certification Ensures Quality Standards for Bearings in the EU Market

CE certification plays a crucial role in ensuring quality standards for bearings in the EU market. The certification process involves rigorous assessments that verify a product's compliance with EU directives, ensuring that it meets essential health, safety, and environmental protection requirements. According to a recent report by the European Commission, nearly 80% of consumers prioritize CE-marked products, emphasizing the certification's vital role in building trust and credibility in the marketplace. This commitment to quality not only protects consumers but also enhances manufacturer accountability.

CE certification plays a crucial role in ensuring quality standards for bearings in the EU market. The certification process involves rigorous assessments that verify a product's compliance with EU directives, ensuring that it meets essential health, safety, and environmental protection requirements. According to a recent report by the European Commission, nearly 80% of consumers prioritize CE-marked products, emphasizing the certification's vital role in building trust and credibility in the marketplace. This commitment to quality not only protects consumers but also enhances manufacturer accountability.

As the EU continues to tighten regulatory frameworks, manufacturers must navigate these complexities to maintain market access. For instance, the In Vitro Diagnostic Regulation (IVDR) imposes stringent requirements on manufacturers, thus highlighting the importance of CE certification as a means of demonstrating compliance. Additionally, the successful certification of products, such as wastewater pumping stations, illustrates how organizations can lead in sustainability while adhering to EU standards. By investing in CE certification, companies in the bearing industry can leverage their compliance as a competitive advantage, reinforcing their commitment to delivering high-quality and reliable products in a demanding market.

Key Steps to Achieve CE Certification for Bearing Products

Achieving CE certification for bearing products is crucial for manufacturers aiming to enter the European Union market. The process involves several key steps that ensure product safety and compliance with EU regulations. Firstly, manufacturers must identify the applicable directives and standards relevant to their products. For bearings, this typically includes the Machinery Directive and the RoHS Directive, among others. According to a 2022 report by the European Association of Manufacturers of Bearings, nearly 75% of bearing producers emphasize the significance of meeting CE criteria to enhance market competitiveness.

Next, manufacturers should conduct thorough risk assessments and product testing. This step is essential to demonstrate that their bearings meet essential requirements for health, safety, and environmental protection. Extensive testing can uncover potential non-conformities early in the development process. Data from Industry Europe indicates that firms investing in robust compliance processes can reduce certification times by up to 30%, optimizing their go-to-market strategies.

**Tips:** Invest in training workshops for your staff on CE marking standards to enhance understanding and compliance. Additionally, consider working with a compliance consultant who can guide you through the documentation process, which is often the most challenging part of CE certification.

Understanding the Importance of CE Certification for Bearings in the EU Market

This chart illustrates the distribution of bearing products in the EU market based on their compliance status with CE certification requirements. The majority of the products are fully compliant, which highlights the importance of adhering to regulatory standards for successful market access.

Common Challenges in the CE Certification Process for Bearings

The CE certification process for bearings in the EU market poses several common challenges that manufacturers must navigate. One primary difficulty is the complexity of compliance with the various directives applicable to these products. Bearers must ensure that they meet the essential requirements outlined in the

Machinery Directive, the

Low Voltage Directive, and others, which can vary significantly depending on the intended use of the bearings. This necessitates not only a deep understanding of regulatory texts but also tailored testing and documentation to demonstrate compliance.

Another challenge lies in the rigorous testing and quality assurance processes required for CE marking. Manufacturers often face obstacles in sourcing accredited testing facilities that can provide the necessary assessments of performance, safety, and environmental impact. Furthermore, the documentation involved in the certification process can be daunting, requiring detailed technical files that include design specifications, risk assessments, and inspection reports. The combination of these factors can lead to delays in the certification timeline, increased costs, and potential market access issues if not managed effectively.

The Role of Testing and Documentation in CE Certification for Bearings

CE certification is crucial for bearings entering the EU market, as it signifies compliance with stringent safety and environmental standards. The certification process involves a series of rigorous testing procedures that assess both performance and durability. Manufacturers must ensure that their bearings meet the essential requirements outlined in relevant European directives, which typically cover aspects such as mechanical safety, noise emissions, and material compatibility.

Documentation plays a pivotal role in the CE certification process. Manufacturers are required to maintain a technical file that includes design specifications, manufacturing processes, and results from any testing conducted. This documentation not only serves to demonstrate compliance during inspections but also acts as evidence in the event of a dispute regarding product safety.

By thoroughly documenting their compliance efforts, manufacturers can foster trust and transparency in the marketplace, ultimately enhancing their competitiveness in the EU bearing industry.

Impact of CE Certification on Market Access and Consumer Trust in the EU

CE certification plays a pivotal role in ensuring that bearings meet essential safety, health, and environmental protection standards, which is crucial for accessing the European Union market. By obtaining CE certification, manufacturers demonstrate their commitment to quality and compliance with EU regulations. This certification is not merely a bureaucratic hurdle; instead, it serves as a gateway that allows products to freely circulate within the EU and enhances their competitiveness. Without CE marking, vendors may find themselves excluded from participating in one of the largest consumer markets in the world.

Furthermore, CE certification significantly influences consumer trust. When buyers see the CE mark on bearings, they are assured that the products have undergone rigorous testing and adhere to established standards. This assurance fosters a sense of reliability and strengthens brand loyalty among consumers. In an era where consumers increasingly prioritize safety and quality, CE certification becomes an invaluable asset for manufacturers, helping to build a positive reputation in the marketplace. By integrating CE certification into their product development process, companies not only comply with regulatory requirements but also enhance consumer confidence in their offerings.

Understanding the Importance of CE Certification for Bearings in the EU Market

| Data Dimension |

Description |

Impact on Market |

| CE Certification Requirements |

Specific standards and regulations that bearings must meet to be sold in the EU. |

Compliance is mandatory for legal market access and reduces risks of penalties. |

| Consumer Trust |

CE mark serves as a signal of quality and safety to consumers. |

Increases consumer confidence and potentially boosts sales. |

| Market Access |

Only CE certified products can be sold in the EU market. |

Non-compliance leads to market exclusion and loss of economic opportunities. |

| Regulatory Changes |

Frequent updates to directives affecting product safety standards. |

Companies must stay informed to maintain compliance and avoid market penalties. |

| Post-Market Surveillance |

Ongoing compliance checks after the product is on the market. |

Ensures long-term product safety and protects consumer interests. |

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us

Specifically, CE Certified Bearings for EU Market play a pivotal role in ensuring that these components meet the necessary safety, health, and environmental protection regulations set forth by the European Union. The significance of obtaining CE certification extends beyond mere paperwork; it serves as a mark of quality and reliability that can substantially enhance a product's marketability.

Specifically, CE Certified Bearings for EU Market play a pivotal role in ensuring that these components meet the necessary safety, health, and environmental protection regulations set forth by the European Union. The significance of obtaining CE certification extends beyond mere paperwork; it serves as a mark of quality and reliability that can substantially enhance a product's marketability.

CE certification plays a crucial role in ensuring quality standards for bearings in the EU market. The certification process involves rigorous assessments that verify a product's compliance with EU directives, ensuring that it meets

CE certification plays a crucial role in ensuring quality standards for bearings in the EU market. The certification process involves rigorous assessments that verify a product's compliance with EU directives, ensuring that it meets