What Are Imported Bearings and Why They Outperform Domestic Alternatives in Industrial Applications?

In the ever-evolving landscape of industrial applications, the choice between imported bearings and domestic alternatives can significantly impact operational efficiency and cost-effectiveness. Recent industry reports indicate that nearly 60% of manufacturing leaders prefer imported bearings due to their higher precision and durability, factors that directly contribute to reduced downtime and maintenance costs. For instance, a comprehensive study by the International Bearing Association highlights that imported bearings can enhance performance by up to 25% compared to their domestic counterparts, particularly in high-load and high-speed applications. As industries strive for excellence amidst competitive pressures, understanding the advantages of imported bearings over domestic alternatives becomes crucial for achieving long-term success and sustainability in manufacturing processes.

Understanding Imported Bearings: Definition and Characteristics

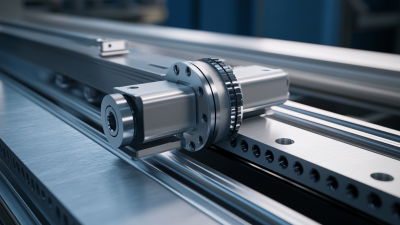

Imported bearings are components manufactured outside a country's borders, often in regions known for advanced engineering and manufacturing practices. These bearings are characterized by superior precision, quality materials, and rigorous testing protocols, which collectively result in enhanced performance in various industrial applications. The intricate manufacturing processes employed by reputable international brands focus on achieving tight tolerances and optimally designed geometries that improve load distribution and minimize friction.

One key characteristic of imported bearings is their innovative design features, such as advanced sealing systems and surface treatments that bolster resistance to wear, corrosion, and environmental factors. These enhancements not only contribute to longer service life but also reduce maintenance needs, leading to increased productivity and cost savings for businesses. In contrast, many domestic alternatives may not match the technological advancements or quality control measures that have become standard in the global market, ultimately limiting their effectiveness in demanding industrial settings.

This chart compares the performance characteristics of imported bearings and domestic alternatives in terms of material quality, precision, durability, cost-effectiveness, and lead time. The data indicates that imported bearings generally outperform domestic bearings across most parameters, highlighting their advantages in industrial applications.

The Advantages of Imported Bearings in Industrial Applications

Imported bearings have gained popularity in industrial applications due to their superior performance and efficiency compared to domestic alternatives. According to a recent study by the International Bearing Association, imported bearings can offer performance improvements of up to 30%, especially in high-speed and precision applications. This is largely attributed to advancements in materials and manufacturing processes utilized by international manufacturers, which often incorporate higher-grade alloys and modern technologies such as computer-aided design (CAD) and precision machining.

Furthermore, imported bearings often come with enhanced durability and reduced maintenance needs. The same study indicates that companies using imported bearings experience up to a 40% decrease in maintenance downtime, translating to significant cost savings and increased productivity. With the ability to withstand higher loads and operate effectively in extreme conditions, these bearings provide industries, particularly in sectors like automotive and aerospace, with reliable solutions that meet rigorous performance standards. As global competition intensifies, the choice of imported bearings ensures that industrial players maintain a competitive edge through innovation and efficiency.

Comparing Imported Bearings with Domestic Alternatives

In the industrial sector, the choice between imported and domestic bearings often comes down to performance and reliability. Recent analyses indicate that imported bearings typically outperform their domestic counterparts in critical aspects such as tolerance, material quality, and lifespan. For instance, a report from an engineering consultancy noted that premium imported bearings can provide up to 30% longer operational life and reduce downtime significantly, which is vital for industries operating on lean schedules.

Furthermore, while tariffs may aim to protect domestic manufacturers, they can inadvertently inflate costs and hinder innovation within local production. Economists argue that tariffs serve as inefficient barriers, resulting in higher prices for consumers and industries reliant on these essential components. The cost-effectiveness and superior performance of imported bearings often lead manufacturers to prefer these products despite potential tariff implications. This trend underscores the importance of quality and reliability in bearing selection for industrial applications, where every fraction of a second in increased productivity can translate into significant financial gains.

Factors Contributing to the Superior Performance of Imported Bearings

Imported bearings have gained a reputation for their superior performance in various industrial applications, and several factors contribute to this distinction. Firstly, the advanced technology and manufacturing processes employed by leading global suppliers allow for higher precision and enhanced durability. These manufacturers often invest significantly in research and development, which results in bearings that exhibit lower friction, reduced wear, and the ability to withstand more extreme operating conditions.

Additionally, imported bearings often utilize superior materials that enhance their overall performance. For instance, advanced steel alloys and specialized coatings can improve resistance to corrosion and fatigue, extending the life of the bearing in challenging environments. Furthermore, strict quality control standards in these manufacturing facilities ensure that each bearing meets high-performance criteria, which is sometimes lacking in domestic alternatives. Consequently, industries counting on reliability and efficiency in their operations find that imported bearings not only meet but often exceed their performance expectations.

Challenges and Considerations in Sourcing Imported Bearings

Sourcing imported bearings comes with unique challenges and considerations, particularly in the context of a rapidly evolving global manufacturing landscape. As industries increasingly seek high-performance solutions, imported bearings often emerge as a preferred choice due to their superior quality and technological advancements. According to a recent industry report, imported bearings can provide up to 30% longer service life compared to their domestic counterparts, largely attributable to advanced production techniques and materials used by leading manufacturers abroad.

However, the journey of sourcing these imported bearings is not without obstacles. Factors such as fluctuating tariffs, stringent compliance regulations, and potential supply chain disruptions pose significant challenges to manufacturers. For instance, with the recent push for China to become a transportation superpower, European manufacturers may face heightened competition and logistical complexities when sourcing from Asian markets. Additionally, as industries in regions such as Argentina grapple with economic instability and inflation, the risk associated with importing components becomes even more pronounced. Understanding these dynamics is crucial for businesses aiming to strike a balance between quality and operational viability when opting for imported bearings.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us