Understanding Industry Standards for Best Thrust Ball Bearings Custom Manufacturing Insights and Data

In the dynamic world of mechanical engineering, the demand for high-performance components is ever-increasing, particularly when it comes to Thrust Ball Bearings Custom Manufacturing. Understanding industry standards is crucial not only for ensuring product quality but also for optimizing after-sales service advantages and minimizing maintenance costs.

As manufacturers delve into the complexities of custom designs, they must navigate various standards and specifications that govern thrust ball bearings. This understanding not only empowers companies to meet client expectations but also enhances operational efficiency and cost-effectiveness in the long run.

This blog aims to explore the vital insights and data surrounding thrust ball bearings, shedding light on how businesses can leverage industry standards to improve their manufacturing processes and service offerings.

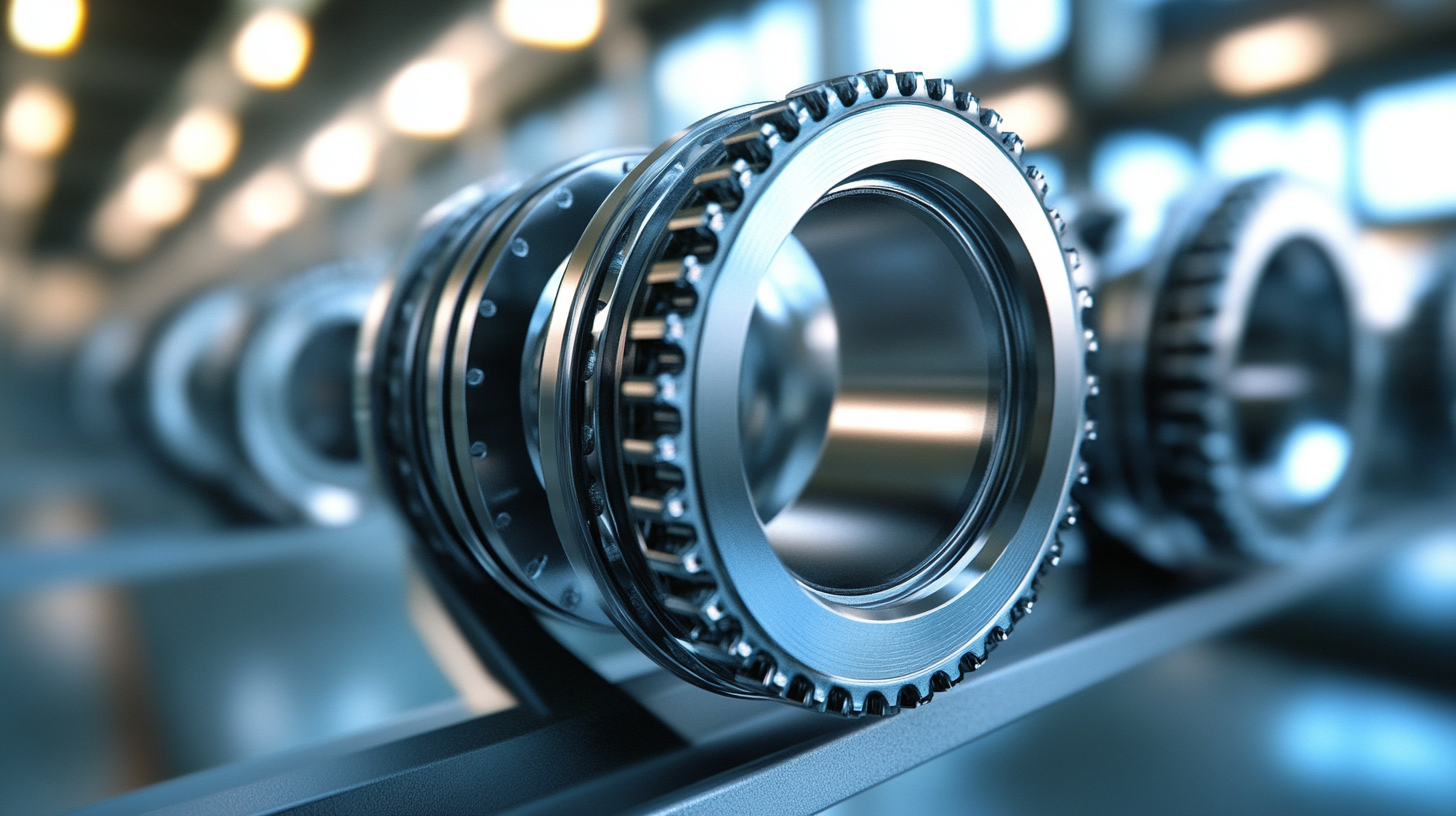

Key Characteristics of High-Performance Thrust Ball Bearings in Custom Manufacturing

Thrust ball bearings play a crucial role in various industrial applications, especially in supporting axial loads with minimal friction. According to the 2023 Global Bearing Market Report, thrust ball bearings account for approximately 15% of the overall bearing market, reflecting their essential function in ensuring machinery efficiency. High-performance thrust ball bearings are characterized by their ability to withstand heavy loads, high speeds, and extreme operating temperatures. These bearings are often manufactured using advanced materials such as high-carbon chromium steel and ceramic elements, which contribute to their enhanced durability and operational longevity.

Custom manufacturing processes emphasize precision and specific material selection to meet unique operational requirements. The latest data indicates that nearly 40% of thrust ball bearings are customized for specific applications—whether in automotive, aerospace, or industrial machinery sectors. Key characteristics of high-performance options include superior surface finish, optimal lubrication methods, and enhanced sealing technologies.

A study from the Bearing Manufacturer's Association also reported that ball bearings with improved geometrical accuracy exhibit a 30% increase in load capacity compared to standard models, paving the way for innovative designs that cater to evolving industry demands.

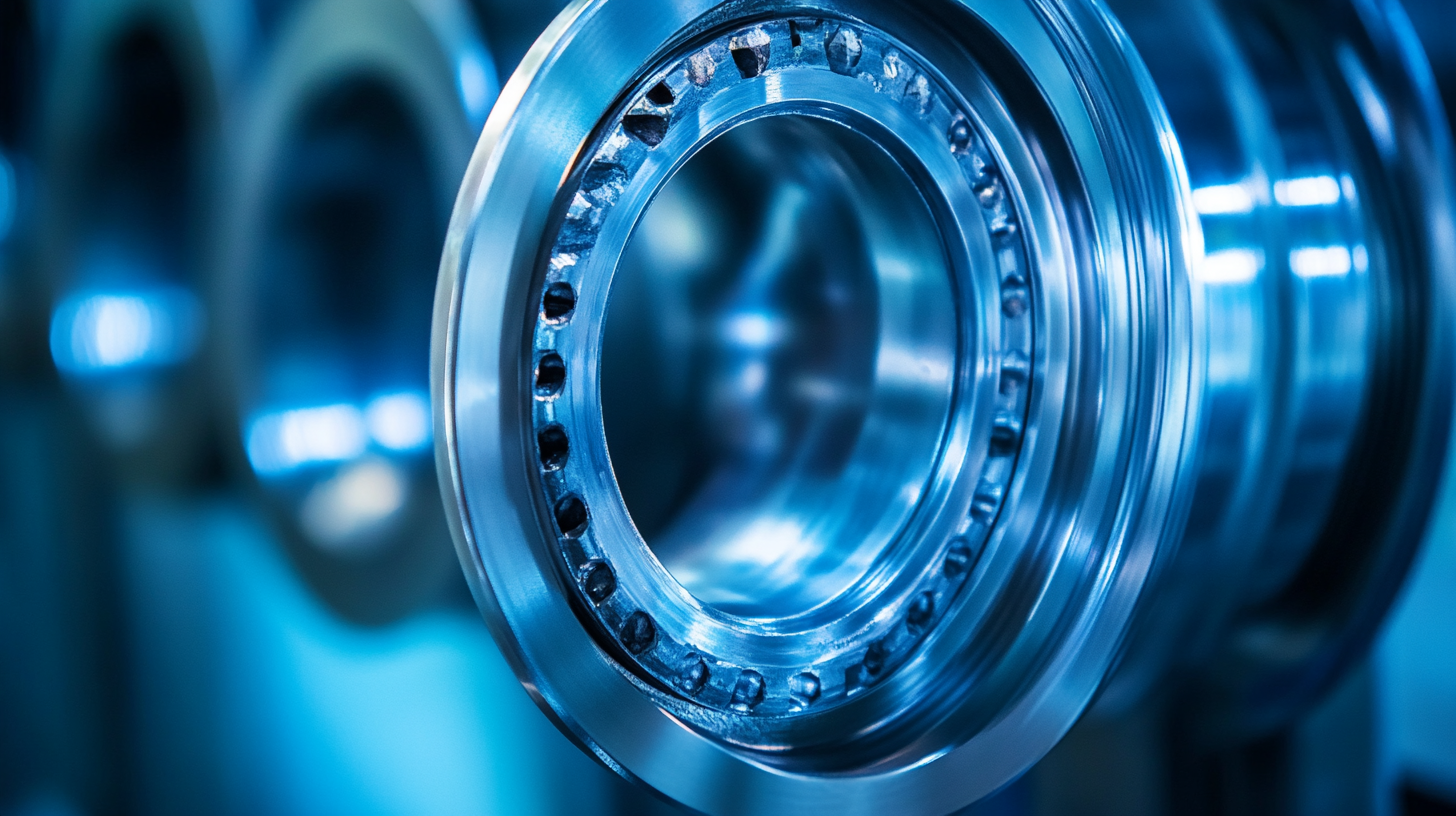

Exploring Material Selection for Optimal Durability and Performance in Bearings

When it comes to thrust ball bearings, material selection plays a pivotal role in ensuring optimal durability and performance. The choice of materials can significantly influence the bearing's load capacity, wear resistance, and overall lifespan. For instance, high-carbon chromium steel, commonly used in bearing manufacturing, offers exceptional hardness and strength, making it a preferred option for applications subjected to heavy loads. According to a recent industry report by Grand View Research, the global bearings market was valued at approximately $80 billion in 2021, with a projected growth rate of 5.3% annually, underscoring the increasing demand for high-performance materials.

Moreover, advancements in composite materials and ceramics are becoming increasingly relevant in the bearing industry. Materials such as silicon nitride provide high fracture toughness and are lightweight, making them suitable for high-speed applications. A study published by the Journal of Materials Science indicated that ceramic bearings can reduce friction by up to 50% compared to traditional steel bearings. This reduction not only enhances performance but also contributes to energy efficiency, aligning with modern manufacturing's sustainability goals. As manufacturers continue to innovate, the focus on material selection is poised to redefine standards for thrust ball bearings, delivering unprecedented performance levels in various industrial applications.

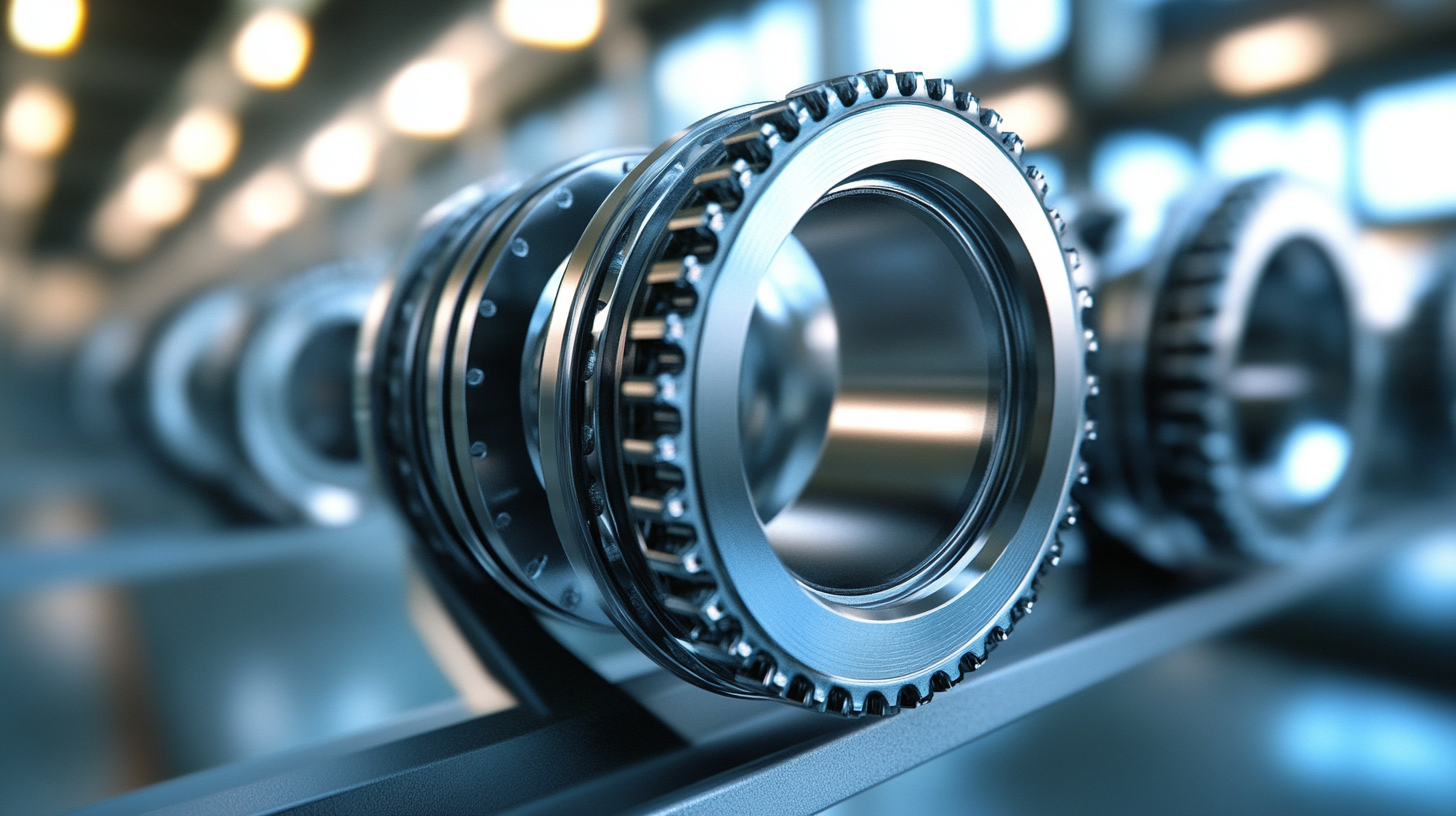

The Role of Precision Engineering in Producing Best-In-Class Thrust Ball Bearings

Precision engineering plays a crucial role in the manufacturing of best-in-class thrust ball bearings, ensuring that these components meet the demanding requirements of various applications across industries. According to the latest industry reports, the global thrust ball bearing market is projected to grow substantially, with a compound annual growth rate (CAGR) of approximately 5.2% from 2022 to 2028. This growth underscores the increasing demand for high-performance bearings that can operate effectively in challenging environments.

Innovations in precision engineering techniques are essential for producing thrust ball bearings that not only meet but exceed these market expectations. Advanced manufacturing processes, including CNC machining and additive manufacturing, allow for enhanced exactness in component dimensions and surface finishes. As reported, components manufactured with high precision can improve operational reliability and performance by up to 30%, making them vital in applications such as robotics, aerospace, and automotive industries. The continuous refinement of these engineering practices is pivotal in delivering thrust ball bearings that promote efficiency and longevity, solidifying their role in the advancement of autonomous systems across air, sea, and space.

Understanding Industry Standards for Best Thrust Ball Bearings Custom Manufacturing Insights and Data

| Dimension (mm) |

Load Capacity (N) |

Material |

Precision Grade |

Application |

| 30 x 62 x 16 |

5000 |

Chromium Steel |

P6 |

Automotive |

| 40 x 80 x 18 |

8000 |

Stainless Steel |

P5 |

Industrial Machinery |

| 50 x 100 x 19 |

10000 |

Carbon Steel |

P4 |

Aerospace |

| 60 x 120 x 22 |

12000 |

Ceramic |

P3 |

Robotics |

Quality Control Measures Essential for Custom Manufacturing of Bearings

In the realm of custom manufacturing, particularly for thrust ball bearings, quality control measures play a pivotal role in ensuring product reliability and durability. The manufacturing process begins with selecting high-grade raw materials, which is essential for achieving superior performance specifications. Rigorous testing throughout the production cycle helps identify potential defects early, allowing manufacturers to address issues before the final product reaches the customer. Implementing standardized testing protocols, such as dimensional inspections and material hardness tests, can greatly enhance the overall quality assurance process.

Beyond raw material quality, manufacturers must also focus on process control throughout production. This includes monitoring machining tolerances, maintaining optimal equipment conditions, and conducting regular maintenance to prevent deviations that could compromise bearing performance. Employing advanced technologies, such as automated inspection systems and real-time monitoring, can significantly improve accuracy in quality control. By prioritizing these measures, companies not only comply with industry standards but also establish a solid reputation for producing high-quality thrust ball bearings that meet or exceed client expectations.

Understanding Industry Standards for Best Thrust Ball Bearings

This chart illustrates the quality control measures essential for the custom manufacturing of thrust ball bearings, highlighting critical factors such as dimensional accuracy and material quality.

Global Market Trends and Demand for Custom Thrust Ball Bearings in Various Industries

The global market for custom thrust ball bearings is witnessing a significant increase in demand, driven by various industries looking for precision and efficiency in their operations. Recent market analysis indicates that the thrust ball bearing segment is expected to grow at a CAGR of over 5% through the next five years, propelled by advancements in manufacturing technologies and the rising need for custom solutions tailored to specific applications. Automotive, aerospace, and manufacturing sectors are among the largest consumers of these components, reflecting the broader trend of customization in industrial products.

As industries evolve, understanding the preferences and requirements of different sectors is paramount. With the rise of automation and smart manufacturing, companies are increasingly opting for specialized thrust ball bearings that enhance operational reliability while minimizing maintenance costs. In 2022, the linear motion products market reached $X billion and is projected to expand significantly, further bolstering the demand for custom bearings and related products.

Tips: When considering the purchase of custom thrust ball bearings, it’s crucial to assess the exact specifications needed for your application, including load capacity and operational speed. Additionally, prioritize vendors that offer comprehensive support and customization capabilities to stay competitive in your industry. Lastly, staying informed about the latest technological developments can help you make better procurement decisions and optimize your production processes.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us