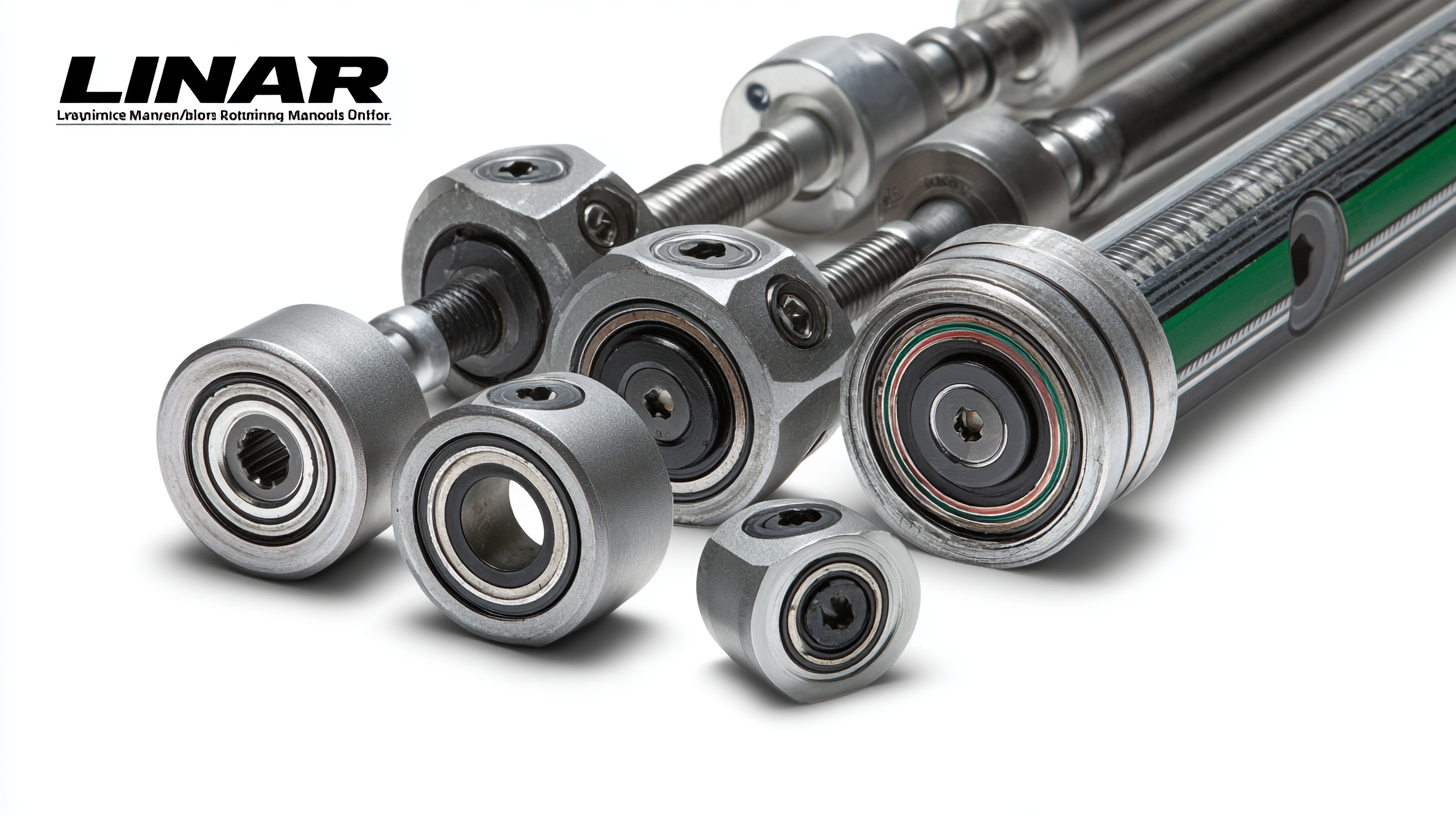

Linear motion bearings are essential components in various mechanical systems, enabling precise movement in a straight line without unwanted friction. They encompass a variety of types, including ball bearings, linear guides, and roller bearings, each serving distinct applications across industries such as automation, robotics, and manufacturing. According to industry reports, the global industrial bearings market is projected to reach USD 363.50 billion by 2034, indicating a robust growth trajectory of 4.31% CAGR. This growth is largely driven by increasing demand for efficient motion control solutions in various machinery.

In recent exploration of linear motion systems, innovations such as rack-and-pinion drives are gaining attention for their ability to provide precise motion over extended distances without the intricacies associated with motor-driven systems. Furthermore, understanding the interplay between linear motion technologies and traditional pneumatic systems is becoming more critical for industries prioritizing speed and force. As engineers continue to delve into emerging technologies and their applications, the significance of linear motion bearings remains paramount in fostering enhanced performance and stability across numerous machinery types.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us