5 Proven Strategies for Maximizing Your Bulk Order of Best Linear Motion Bearings

In the increasingly competitive landscape of manufacturing and automation, optimizing procurement processes is paramount, particularly when it comes to acquiring essential components like linear motion bearings. According to a recent industry report by MarketsandMarkets, the global linear motion systems market is expected to reach USD 8.83 billion by 2025, growing at a CAGR of 6.2%. This surge in demand underscores the importance of strategic purchasing practices, especially for companies looking to maximize their investments through Linear Motion Bearings Bulk Order. Implementing effective strategies not only ensures cost efficiency but also enhances the overall performance and longevity of machinery applications.

In this blog, we will explore five proven strategies that can significantly optimize your bulk orders of the best linear motion bearings, paving the way for greater operational efficiency and savings.

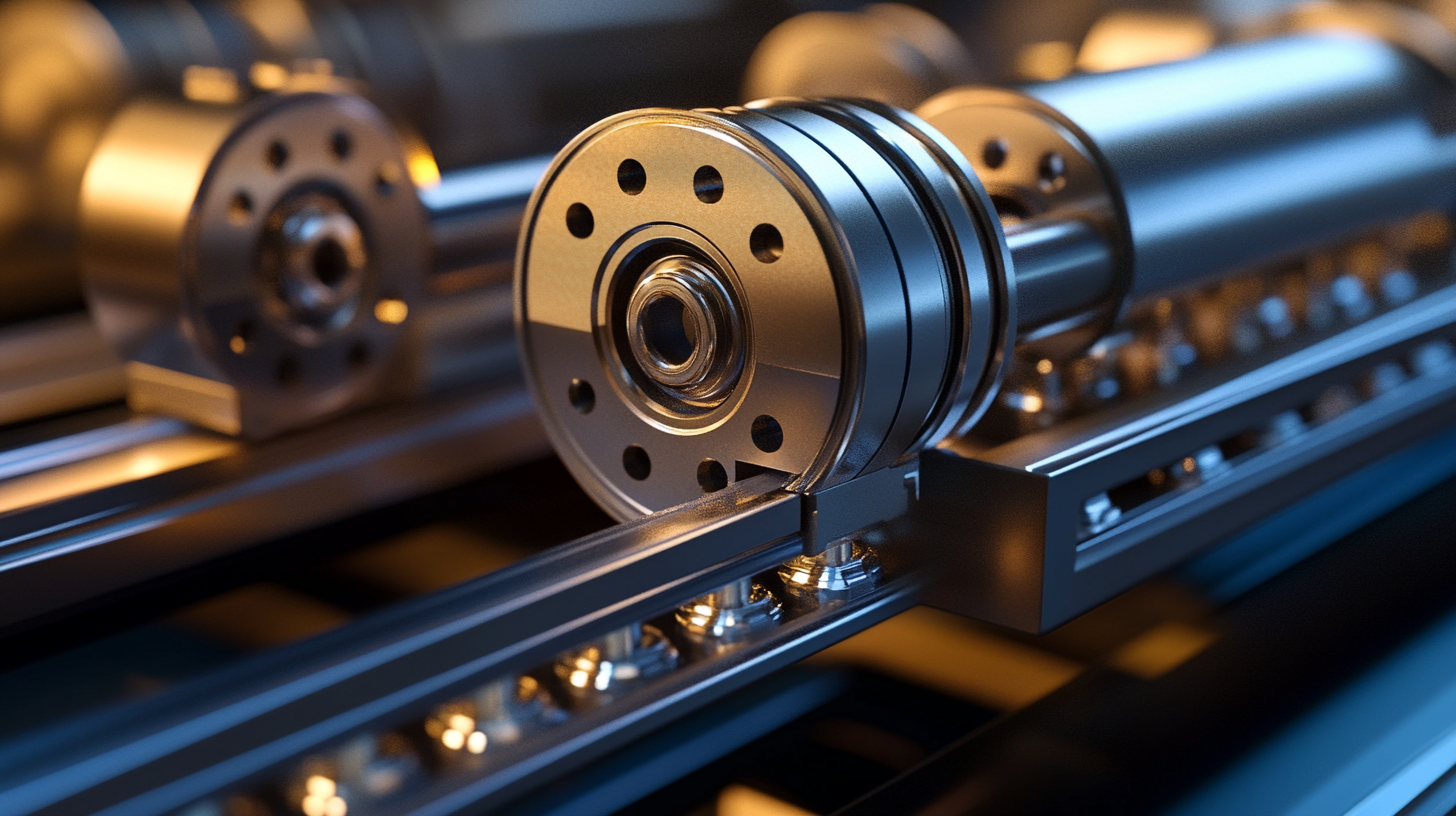

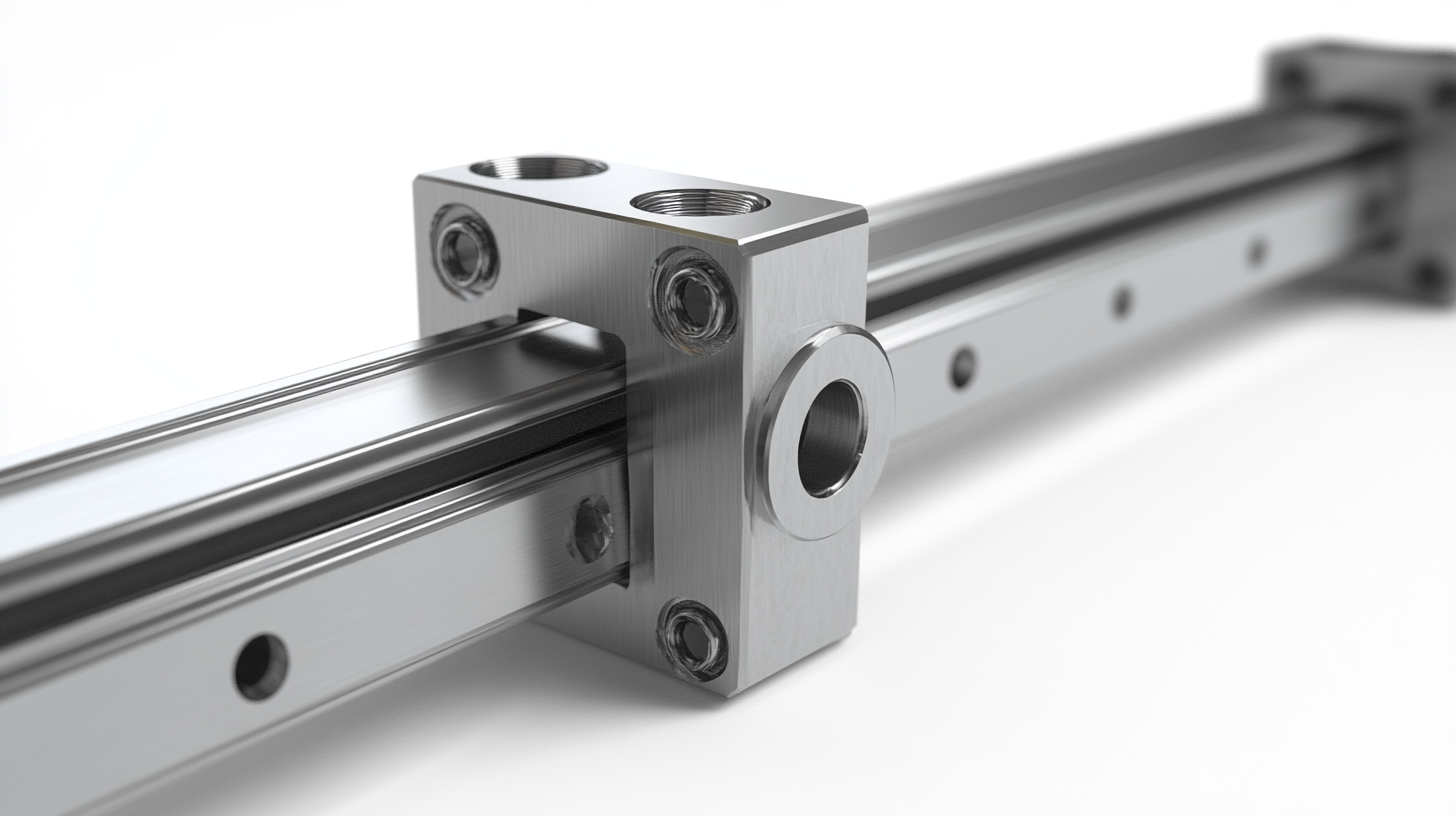

Understanding the Importance of Linear Motion Bearings in Modern Applications

Linear motion bearings play a crucial role in various modern applications, from industrial machinery to robotics. These components ensure smooth movement and precise positioning, essential for achieving high efficiency and accuracy in operations. Their significance extends to sectors like automotive, aerospace, and manufacturing, where reliability is key. Understanding their importance allows businesses to make informed decisions about bulk ordering, ultimately leading to enhanced performance and reduced costs.

When maximizing your bulk order of linear motion bearings, consider the following tips. First, assess the specific requirements of your application to select the most suitable bearing type and size. This will ensure that you get the right components that can withstand the operational demands. Second, establish a relationship with a reputable supplier who offers quality assurance and after-sales support. This will help mitigate any risks associated with potential defects or failures. Lastly, keep an inventory of different bearing types, as this flexibility can help you respond quickly to changing project needs and maintain operational efficiency.

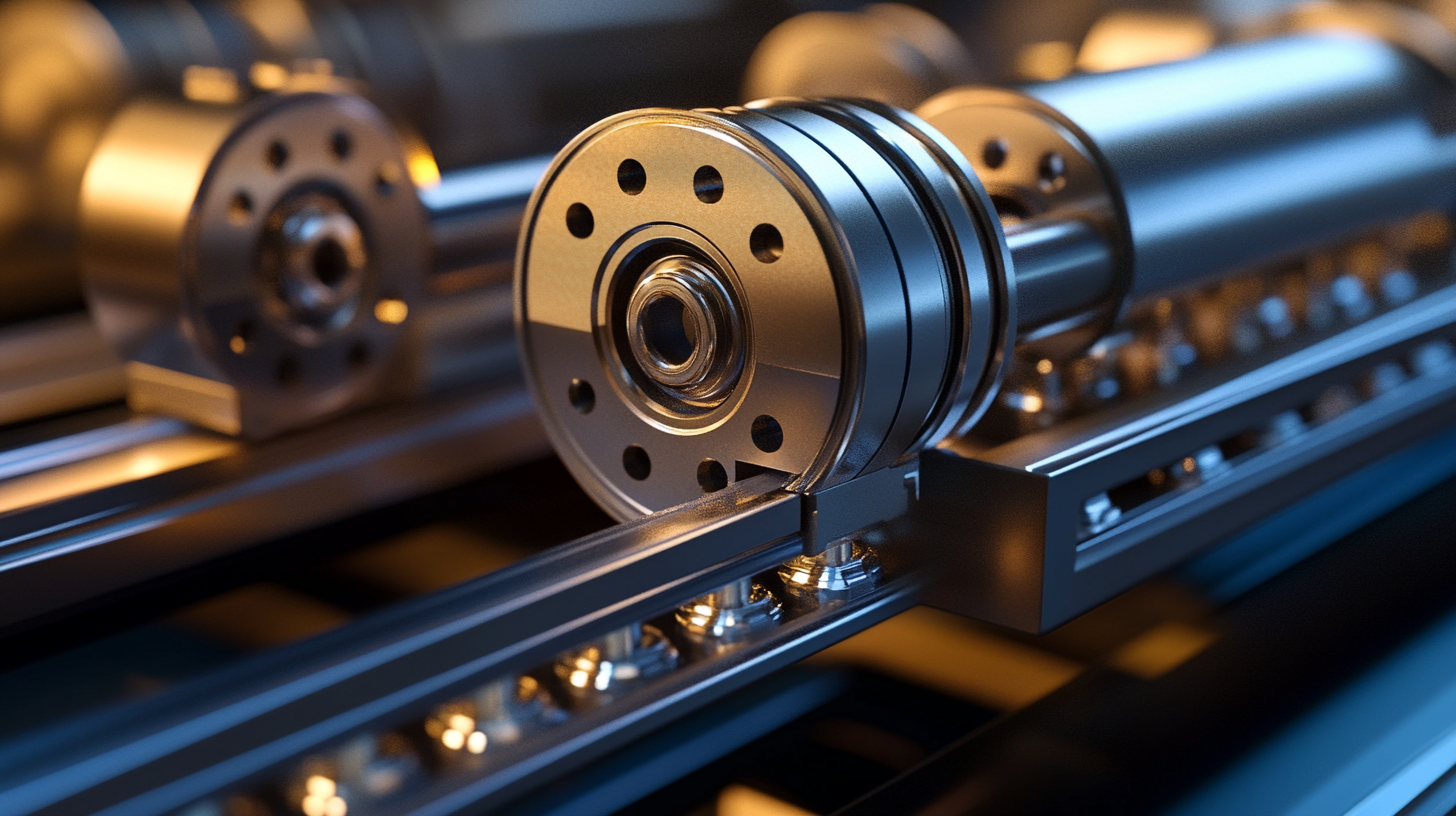

Evaluating the Quality of Bulk-Purchased Bearings for Optimal Performance

When it comes to maximizing bulk orders of linear motion bearings, evaluating quality is paramount for optimal performance. Bearings are essential components in various mechanical applications, directly affecting efficiency and longevity. Therefore, inspecting the precision of manufacturing processes and materials used is crucial. Look for certifications and testing standards that confirm the bearings meet necessary performance criteria. Moreover, understanding the specific operational demands they will face is vital, as this can guide the selection process towards bearings that align with your operational expectations.

Additionally, establish a reliable line of communication with suppliers to foster transparency regarding production practices. This partnership can ensure that you're informed of any potential issues in manufacturing or material sourcing prior to placing your bulk order. Moreover, request detailed specifications and performance data for the bearings to further assist in your evaluation. By taking these steps, not only do you enhance your chances of securing high-quality bearings, but you also contribute to the overall efficiency of your machinery, ultimately leading to better operational outcomes.

Maximizing Bulk Order Quality: Linear Motion Bearings Evaluation

Cost-Effectiveness: Balancing Price and Quality in Bulk Orders

When considering bulk orders of linear motion bearings, achieving a balance between price and quality is paramount. To maximize your investment, it’s essential to evaluate different suppliers and their offerings. Low prices might be tempting, but they can often signify inferior materials or less stringent quality control. Aim for manufacturers who provide detailed specifications and certifications; this helps ensure that the bearings will perform reliably in your applications.

When considering bulk orders of linear motion bearings, achieving a balance between price and quality is paramount. To maximize your investment, it’s essential to evaluate different suppliers and their offerings. Low prices might be tempting, but they can often signify inferior materials or less stringent quality control. Aim for manufacturers who provide detailed specifications and certifications; this helps ensure that the bearings will perform reliably in your applications.

One effective tip is to conduct thorough research before placing your bulk order. Gather samples from different suppliers and conduct performance tests. This allows you to assess quality firsthand before committing to a larger purchase. Additionally, consider long-term costs such as maintenance and replacement, as these can significantly affect your overall budget. Investing in high-quality bearings from reputable suppliers may have a higher upfront cost but could save you money in the long run by reducing failure rates and maintenance needs.

Lastly, don’t hesitate to negotiate with suppliers. When ordering in bulk, you might have leverage to obtain better pricing or additional quality guarantees. Cultivating strong relationships with suppliers can also lead to personalized service and insights into future product improvements, enhancing your overall purchasing experience. Balancing cost and quality requires diligence, but the results are worth it for optimal performance and durability.

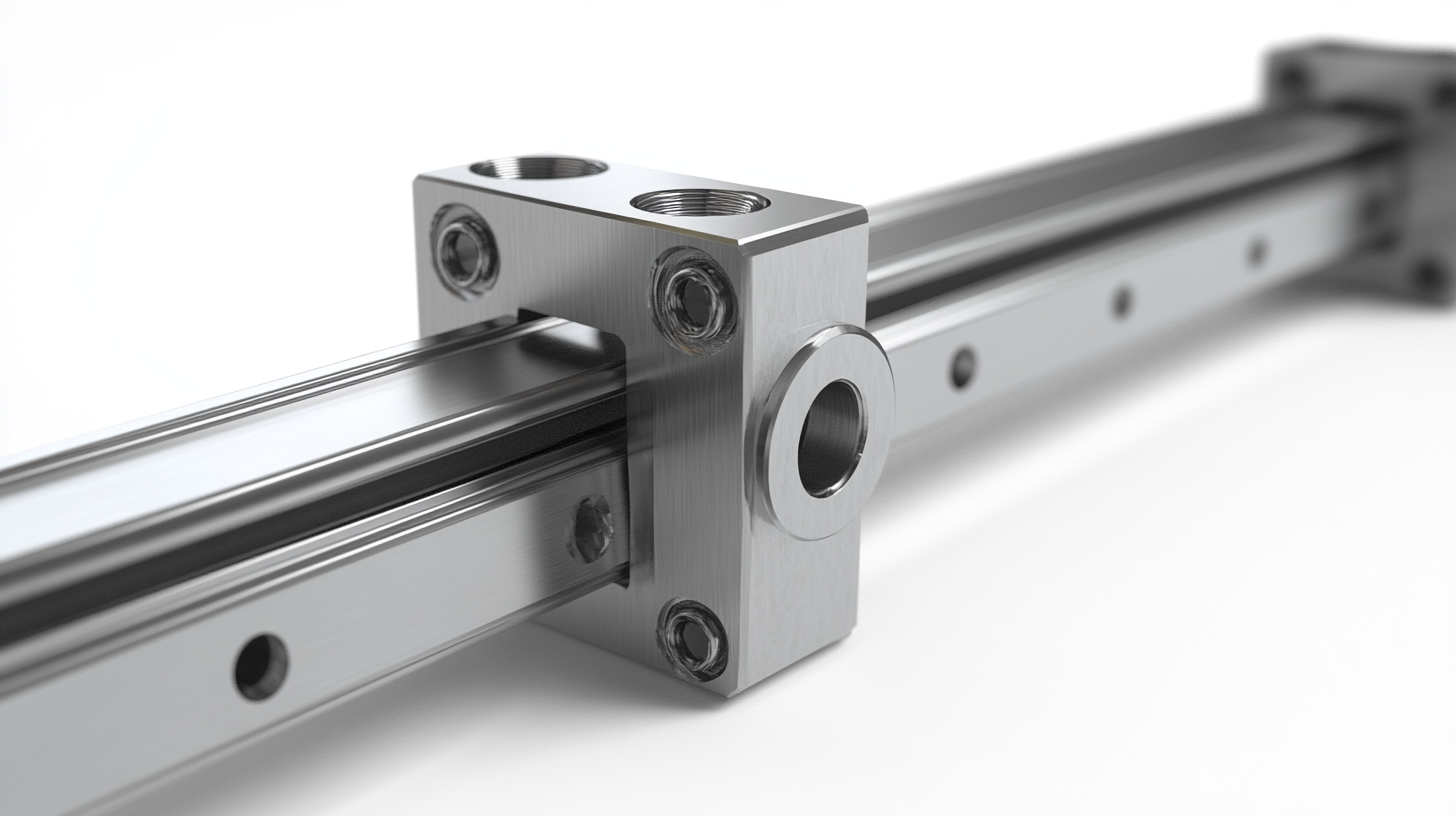

Strategies to Enhance Inventory Management for Linear Motion Bearings

Efficient inventory management is crucial for businesses dealing with linear motion bearings, especially when purchasing in bulk. According to a report by the Linear Motion Industry Association, nearly 42% of companies experience challenges with inventory turnover, which affects their cash flow and operational efficiency. Implementing a robust inventory management system can significantly enhance your ability to track stock levels and maintain optimal quantities, reducing the risk of overstocking or stockouts.

One effective strategy is to adopt data-driven forecasting techniques. Research from the Institute of Supply Chain Management indicates that businesses utilizing predictive analytics improve their forecasting accuracy by 25%, leading to more informed purchasing decisions. By analyzing historical sales data and market trends, companies can better anticipate demand for linear motion bearings, enabling them to place bulk orders that align with market needs while minimizing excess inventory. Moreover, integrating inventory management software with your procurement processes can streamline operations, reduce manual errors, and enhance visibility throughout the supply chain.

5 Proven Strategies for Maximizing Your Bulk Order of Best Linear Motion Bearings

| Strategy |

Description |

Benefit |

Implementation Tips |

| Volume Discounts |

Negotiate lower prices by ordering in bulk. |

Cost Savings |

Research suppliers open to volume negotiations. |

| Inventory Optimization |

Use software to track stock levels and predict future needs. |

Avoid Stockouts |

Implement an automated inventory management system. |

| Supplier Relationships |

Build strong relationships for better service and terms. |

Reliability |

Regular check-ins and open communication foster trust. |

| Quality Control |

Inspect bearings upon receipt to ensure quality standards. |

Reduce Returns |

Establish clear quality criteria before orders are made. |

| Demand Forecasting |

Analyze trends to predict future demands accurately. |

Efficient Ordering |

Use historical data to create predictive models. |

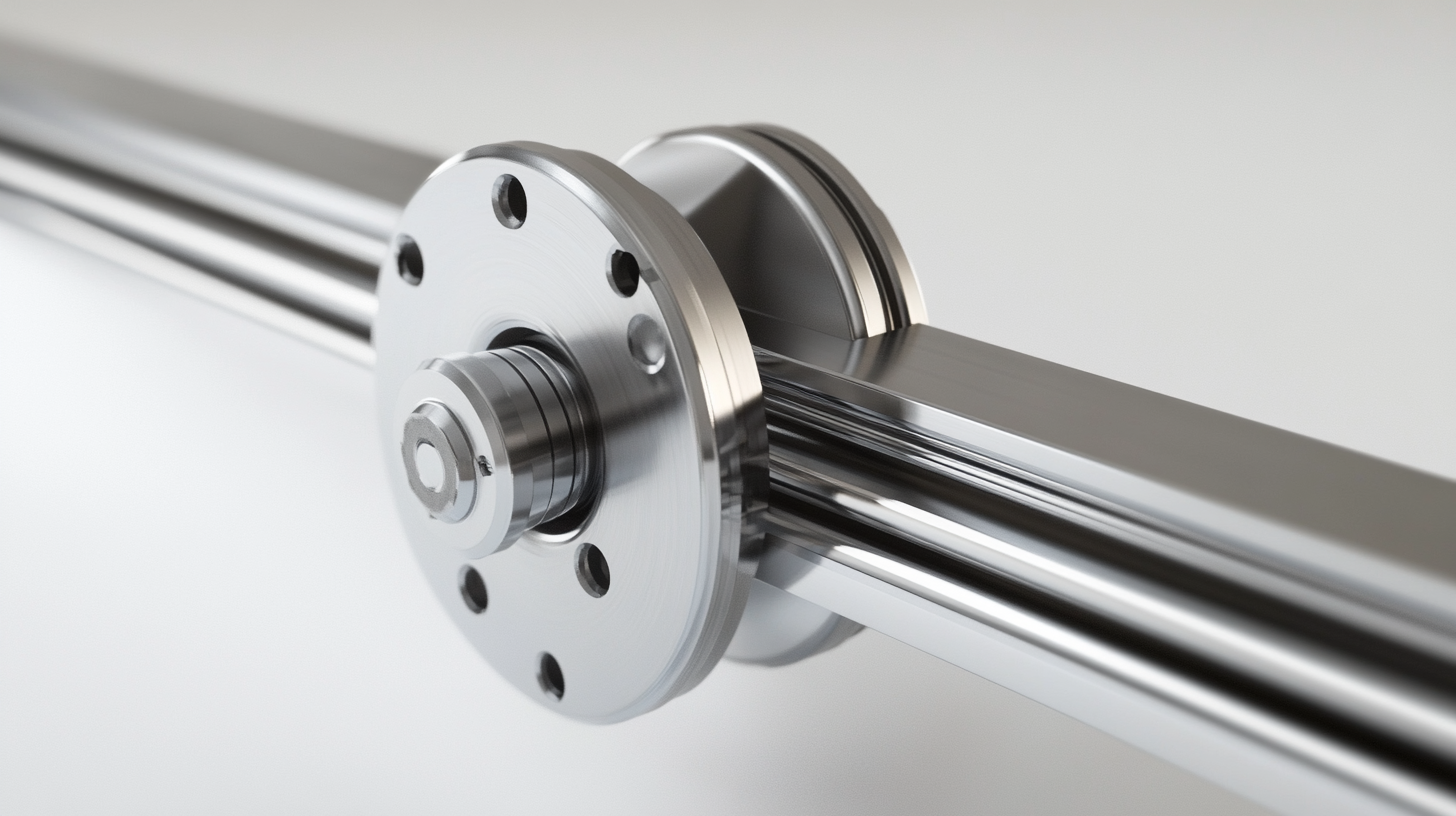

Leveraging Supplier Relationships for Better Bulk Order Deals

Building strong supplier relationships is crucial when it comes to maximizing the benefits of bulk orders, particularly for linear motion bearings. By fostering open communication and trust with your suppliers, you can negotiate better pricing and terms, ensuring that you get the best value for your investment. It's essential to provide feedback on product quality and service, as this not only helps improve the supplier's offerings but also positions you as a valued customer. When suppliers see you as a partner rather than just another client, they are more likely to provide concessions and priority service.

In addition to open communication, regularly engaging with your suppliers can lead to uncovering new opportunities for cost savings. Suppliers often have access to bulk discounts or promotional offers that may not be widely advertised. By discussing your specific needs and future projects, you can position yourself to take advantage of these offerings. Moreover, developing a long-term relationship allows for collaborative problem-solving; suppliers are more likely to prioritize your orders and offer flexible solutions to meet your demands efficiently. This synergy can play a pivotal role in ensuring your bulk orders run smoothly, enhancing both quality and cost-effectiveness in your procurement processes.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us

When considering bulk orders of

When considering bulk orders of