Maximizing Equipment Longevity: Expert Bearing Maintenance Strategies and Superior After-Sales Support

In today's competitive industrial landscape, the longevity of equipment is paramount for operational efficiency and cost-effectiveness. A recent study by the Machinery Maintenance Institute highlights that effective Bearing Maintenance & After-Sales Support can extend the lifespan of machinery by up to 30%, significantly reducing downtime and repair costs. The performance of bearings, which are critical components in various machines, can be adversely affected by poor maintenance practices, leading to premature failures that can disrupt production schedules.

Implementing expert strategies for bearing upkeep—such as regular inspections, lubrication, and temperature monitoring—coupled with robust after-sales support from manufacturers, plays a vital role in maximizing equipment performance. By prioritizing these practices, industries can not only enhance productivity but also achieve substantial savings, ultimately driving better returns on investment.

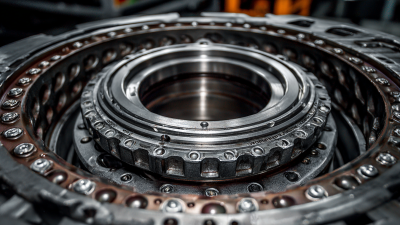

Understanding the Importance of Bearing Maintenance for Extended Equipment Life

Effective bearing maintenance is crucial for extending the life of equipment across various industries. Recognizing this need, the recent launch of the MaPro Xpress initiative highlights the importance of using specialized maintenance products designed to enhance bearing service life. By implementing regular maintenance strategies and utilizing high-quality products, companies can significantly reduce unexpected equipment failures and improve overall operational efficiency.

**Tips:**

1. Regularly inspect bearings for signs of wear or misalignment, as early detection can prevent more severe damage and costly repairs.

2. Utilize vibration analysis techniques to monitor the condition of bearings, providing insights into their performance and enabling timely maintenance decisions.

Additionally, predictive maintenance solutions, including the use of advanced algorithms and sensor data, can transform operational practices. These systems not only forecast potential bearing failures but also optimize maintenance schedules, leading to reduced downtime and increased reliability of mining and manufacturing processes. By staying ahead of maintenance needs, organizations can enhance productivity and protect their investments in equipment.

Key Practices for Effective Bearing Inspection and Maintenance

Effective bearing inspection and maintenance are crucial for maximizing equipment longevity. According to a report by the International Journal of Engineering Research and Applications, proper bearing maintenance can extend equipment life by up to 50%. Bearings are integral to machinery operations, and neglecting their upkeep can result in premature failures and costly downtime. Regular inspections, lubrication management, and alignment checks are key practices that can help maintain optimal performance.

Tip: Always monitor bearing temperature during operation. Excessively high temperatures can indicate lubrication failure or misalignment, signaling the need for immediate attention.

Additionally, incorporating condition monitoring technologies can enhance maintenance strategies. Sensors can provide real-time data on vibration and acoustic emissions, which are essential for identifying potential failures before they occur. A study by the American Society of Mechanical Engineers highlights that predictive maintenance can reduce operational costs by as much as 12% by minimizing unplanned outages.

Tip: Schedule routine analysis to assess vibration patterns and detect anomalies early, ensuring long-term reliability in machinery performance.

Leveraging Technology for Predictive Maintenance in Bearings

In the realm of predictive maintenance for bearings, the integration of digital technologies has proven vital for enhancing equipment longevity. Studies indicate that over 50% of unplanned downtime in manufacturing is attributed to machine wear, emphasizing the need for innovative strategies. By utilizing AI and machine learning, companies can perform real-time analysis of vibration signals and other operational metrics, enabling proactive identification of potential failures. This not only prolongs the lifespan of rotating equipment but also significantly reduces maintenance costs by optimizing intervention timing.

Moreover, the application of advanced analytics presents a transformative opportunity for firms to gain actionable insights into their equipment’s health. Implementing a predictive maintenance framework can reportedly reduce maintenance costs by up to 30% while improving equipment availability by nearly 20%. As industries evolve towards Industry 4.0, the shift to smart data utilization is imperative; organizations can leverage these insights to initiate timely interventions, thus preventing costly breakdowns and enhancing overall production efficiency. By embracing these cutting-edge strategies, manufacturers can navigate the complexities of machinery maintenance, ensuring sustained performance and reliability.

The Role of After-Sales Support in Enhancing Equipment Performance

The role of after-sales support in enhancing equipment performance cannot be overstated, especially in industries where machinery plays a crucial role in operations. According to recent industry reports, companies that invest significantly in after-sales services see a remarkable increase in customer satisfaction and equipment longevity. For example, businesses that offer comprehensive support packages—including maintenance, training, and prompt repair services—experienced revenue growth rates up to 25% higher than their competitors who do not prioritize such services.

Furthermore, aftermarket services are emerging as a vital component for industrial manufacturers. Research indicates that companies focusing on these services not only enhance their overall sales but also achieve higher profit margins. The market for aftermarket support can represent as much as 40% of a manufacturer’s total revenue, emphasizing that robust after-sales strategies are essential for maintaining competitive advantage. By treating customers throughout the lifecycle of their equipment, companies foster loyalty and drive repeat business, ultimately ensuring long-term operational success.

Maximizing Equipment Longevity: Expert Bearing Maintenance Strategies and Superior After-Sales Support

| Maintenance Strategy |

Frequency |

Expected Lifespan Extension (%) |

After-Sales Support Type |

Customer Satisfaction Rating |

| Regular Lubrication |

Every 3 Months |

20% |

Technical Support |

85% |

| Vibration Analysis |

Monthly |

15% |

Monitoring Services |

90% |

| Temperature Monitoring |

Bi-Weekly |

10% |

Custom Alerts |

88% |

| Component Inspections |

Every 6 Months |

25% |

Consultation Services |

92% |

| Condition-Based Monitoring |

As Needed |

30% |

Field Support |

95% |

Training Your Team: Essential Skills for Optimal Bearing Care and Maintenance

Training your team in essential bearing care and maintenance is crucial for maximizing equipment longevity. A well-informed workforce possesses the skills to identify early signs of wear, implement preventive measures, and perform regular maintenance checks. This proactive approach not only reduces unexpected downtime but also extends the life of machinery, ensuring that operations remain smooth and efficient. Training sessions should cover topics such as proper lubrication techniques, alignment procedures, and the significance of maintaining optimal operating conditions.

Moreover, fostering a culture of continuous learning regarding bearing maintenance can empower employees to take ownership of their roles. Regular workshops and hands-on training equip team members with practical skills, enhancing their understanding of how bearings function and the common pitfalls to avoid. With the right knowledge, your team can effectively troubleshoot issues, thus minimizing repair costs and enhancing overall productivity. Empowering staff with these critical skills helps create a robust maintenance framework that supports the longevity of your equipment.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us