Top 10 Middle East High-Temperature Bearings for Extreme Performance

In the harsh and demanding climate of the Middle East, industries are continuously challenged to maintain efficiency and reliability in their operations. One of the critical components that play a pivotal role in ensuring optimal performance under extreme conditions is the Middle East High-Temperature Bearings. These specialized bearings are designed to withstand elevated temperatures while providing the durability and functionality required in various applications, from oil and gas extraction to power generation and transportation.

As the region's industrial landscape evolves, so too does the need for advanced bearing solutions that can endure the rigors of high temperatures and corrosive environments. This article explores the top 10 Middle East High-Temperature Bearings that have been optimized for exceptional performance. We will delve into the engineering innovations and materials that make these bearings suitable for extreme conditions, highlighting their significance in enhancing machinery reliability and operational efficiency.

Understanding the importance of these high-temperature bearings is crucial for businesses aiming to maintain competitiveness in a challenging ecosystem. Join us as we uncover the leading solutions tailored for the unique demands of the Middle East's industrial sectors.

Top 10 High-Temperature Bearings for the Middle East Industry

In the scorching environments of the Middle East, high-temperature bearings are crucial for maintaining operational efficiency in various industries. The extreme heat and sandy conditions pose significant challenges, necessitating specially designed bearings that can withstand elevated temperatures while ensuring optimal performance. Industries such as oil and gas, construction, and manufacturing rely heavily on these components to minimize downtime and enhance reliability.

The top models favored in the region often feature advanced materials like ceramics and high-performance polymers, which provide superior heat resistance and durability. Many of these bearings are engineered to operate effectively at temperatures exceeding 200°C, making them ideal for heavy machinery and equipment that operate in harsh conditions. As the demand for sustainable practices rises, these high-temperature bearings are also being engineered for improved energy efficiency and lower maintenance costs, further supporting the growth of industrial operations across the Middle East.

Top 10 High-Temperature Bearings for the Middle East Industry

Understanding High-Temperature Bearing Performance in Extreme Environments

High-temperature bearings are essential components in various industries, particularly in extreme environments where conventional materials may fail. Understanding the performance characteristics of these specialized bearings is crucial for ensuring reliability and efficiency. Recent advancements in material science, such as nanostructured thermal barrier coatings, indicate significant potential for enhancing the performance of bearings under high-temperature conditions. These coatings provide an additional layer of protection, allowing bearings to withstand both mechanical and thermal stresses more effectively.

The ongoing research into advanced materials complements the growing demand for high-performance bearings, particularly in aerospace and automotive sectors. Specialized aircraft bearings, for instance, are engineered to manage the dual challenges of extreme heat and pressure, highlighting the critical role they play in ensuring operational safety and precision. Moreover, as the high heat bearing market is set to grow robustly, there is a clear need for innovative solutions that can meet the rigorous demands of modern applications, reinforcing the importance of research into high-temperature performance in extreme environments.

Top 10 Middle East High-Temperature Bearings for Extreme Performance

| Bearing Type |

Max Temperature (°C) |

Material |

Load Capacity (kN) |

Lubrication Type |

Application |

| Ceramic Ball Bearing |

200 |

Silicon Nitride |

15 |

Grease |

Aerospace |

| Stainless Steel Bearing |

180 |

440C Stainless Steel |

20 |

Oil |

Marine Equipment |

| Polymer Bearing |

150 |

PTFE |

10 |

Dry |

Food Processing |

| High-Temperature Roller Bearing |

250 |

Cobalt Chrome |

30 |

Solid Lubricant |

Energy Sector |

| Hybrid Bearing |

220 |

Steel and Ceramic |

25 |

Grease |

Industrial Machinery |

| Graphite Bearing |

200 |

Graphite Composite |

12 |

Solid Lubricant |

Paper and Pulp |

| Ceramic Slide Bearing |

180 |

Alumina |

15 |

Oil |

Automotive |

| Heat-Resistant Bearing |

250 |

Nickel Alloy |

35 |

Grease |

Aerospace |

| Silicone Rubber Bearing |

150 |

Silicone |

10 |

Dry |

Electronics |

| Teon Bearing |

200 |

PTFE Composite |

8 |

Dry |

Pharmaceuticals |

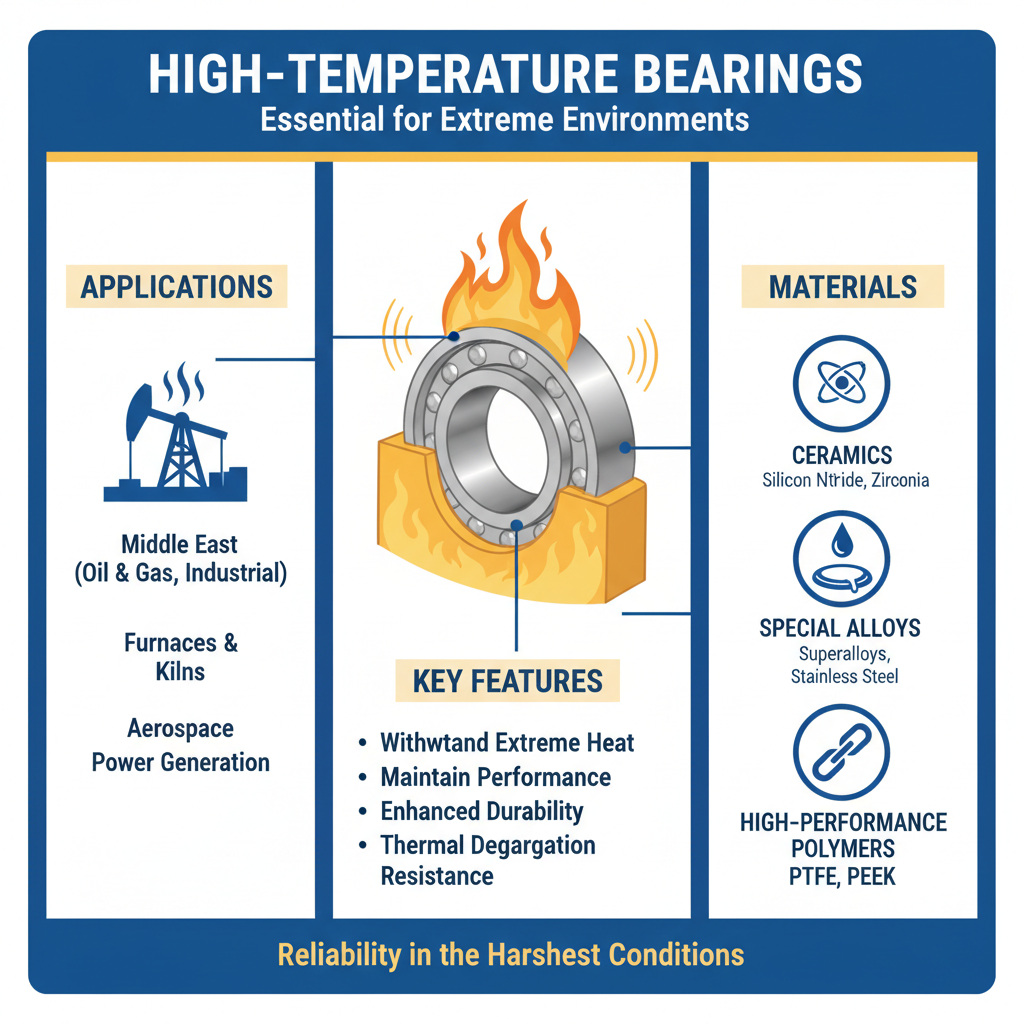

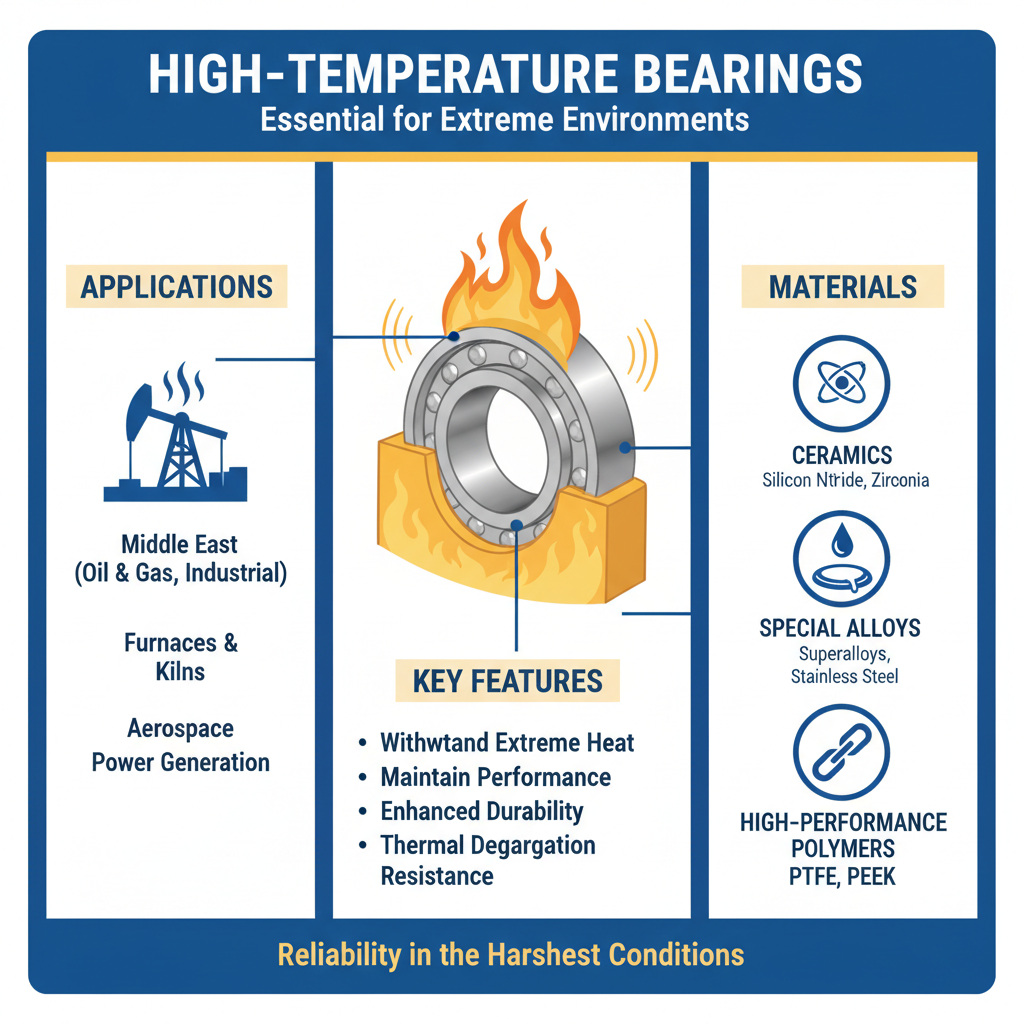

Key Materials Used in High-Temperature Bearings for Harsh Conditions

High-temperature bearings are essential for applications in extreme environments, especially in the harsh conditions often found in the Middle East. These bearings are designed to withstand elevated temperatures while maintaining their performance and integrity. The key to their effectiveness lies in the materials used in their construction.

Materials such as ceramics, special alloys, and high-performance polymers have emerged as frontrunners in the development of these bearings, providing enhanced durability and resistance to thermal degradation.

Ceramic materials, particularly silicon nitride, are increasingly popular due to their lightweight properties and superior thermal stability. These ceramics can withstand higher temperatures than traditional steel, making them ideal for environments where heat can compromise performance.

Additionally, specialized alloys, like cobalt-chromium, offer remarkable strength and corrosion resistance, ensuring that bearings can endure both high temperatures and abrasive conditions. High-performance thermoplastics also play a crucial role, offering excellent chemical resistance and lower friction coefficients, which further enhance the longevity and reliability of high-temperature bearings in demanding applications.

Comparative Analysis of Load Ratings for Middle East Bearings

The comparative analysis of load ratings for high-temperature bearings in the Middle East reveals crucial insights into their performance under extreme conditions. With the regional bearings market projected to grow significantly, from USD 50.16 billion in 2025 to approximately USD 97.10 billion by 2030, understanding the features and load capacities of these bearings becomes essential for industries reliant on robust mechanical components.

High-temperature bearings are specifically designed to withstand elevated operational temperatures, an essential requirement in various applications ranging from oil and gas to renewable energy sectors prevalent in the Middle East. Analyzing the load ratings provides a deeper understanding of how these bearings perform under stress, potentially influencing maintenance cycles and reducing downtime. The findings highlight that materials and design innovations, such as ceramic and hybrid bearings, contribute to enhanced load ratings, pushing the performance boundaries even further. This comparative perspective not only aids manufacturers in selection processes but also assists end-users in optimizing their operational efficiency in the harsh Middle Eastern climate.

Innovative Technologies Enhancing Bearings for Extreme Heat Applications

In the demanding environments of the Middle East, bearings face extreme heat and pressure, necessitating

cutting-edge technology to ensure reliable performance. Innovative materials, such as ceramic composites

and advanced polymers, are being developed to withstand high temperatures without sacrificing durability.

These enhancements not only extend the lifespan of bearings but also reduce maintenance costs, making

them an essential investment for industries operating in harsh conditions.

Tip: When selecting high-temperature bearings,

consider the specific environmental conditions, including temperature ranges and potential contaminants.

This will help in choosing the most suitable material and design configuration.

Additionally, advancements in lubrication technology are playing a critical role in high-temperature applications.

Specialized lubricants designed to remain stable at elevated temperatures significantly improve the efficiency

and performance of bearings. These innovations have led to the development of self-lubricating bearings that

require minimal maintenance, thus offering a competitive advantage in reducing downtime.

Tip: Regularly check and maintain the lubrication

system of your bearings to ensure optimal performance, especially in extreme conditions where traditional

lubricants may break down more quickly.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us