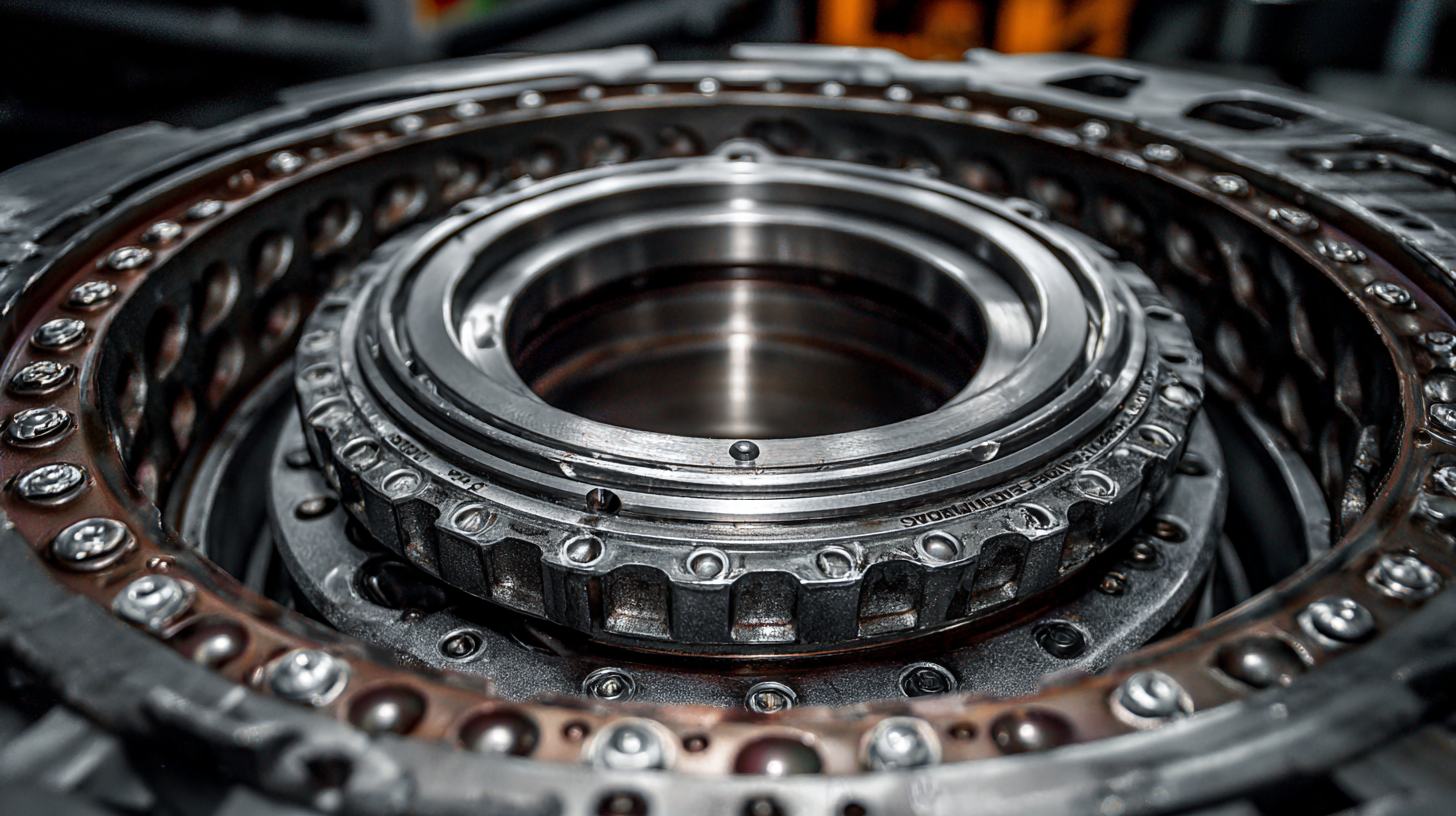

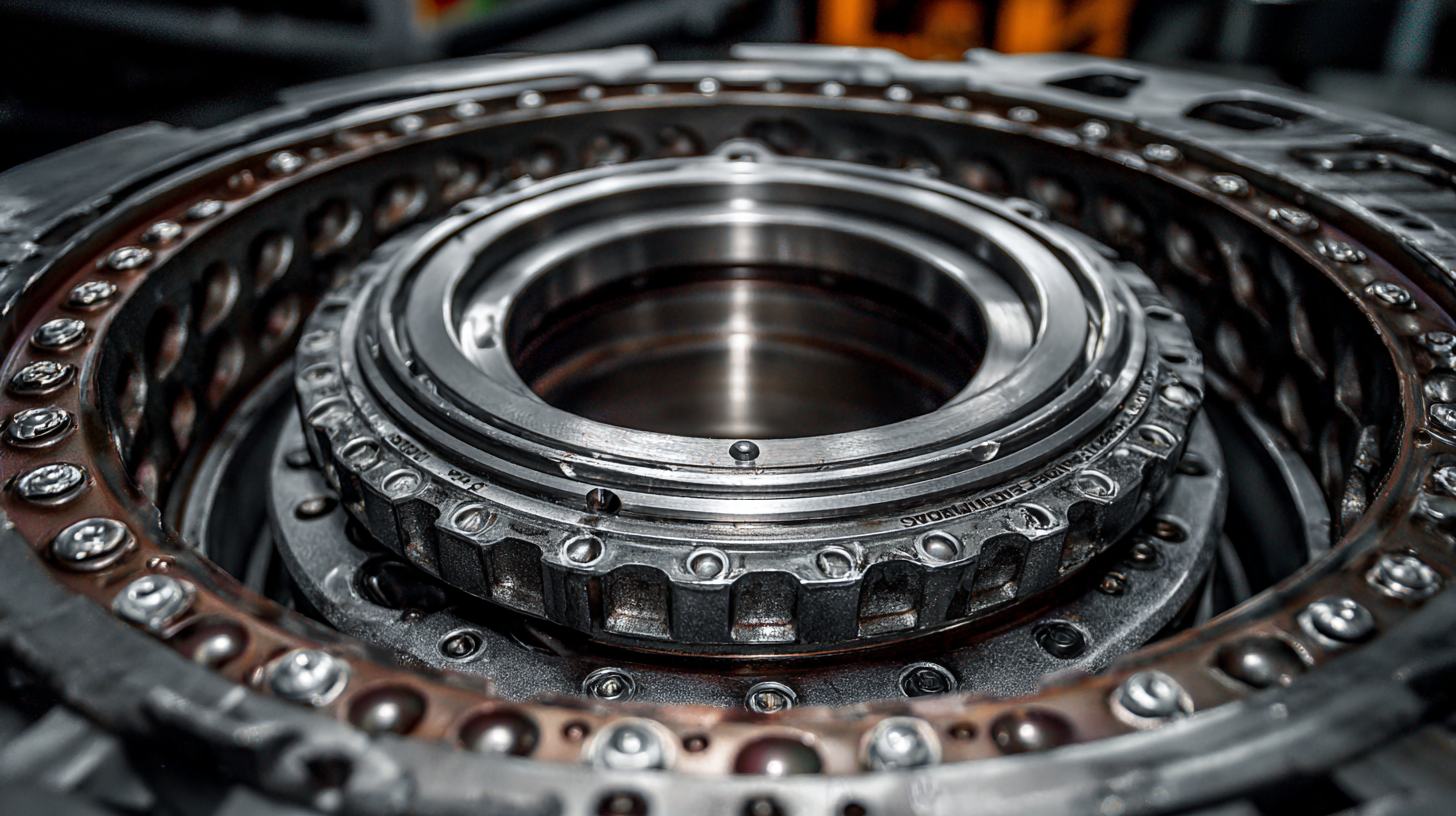

Solutions for Optimal Bearing Longevity and Exceptional After Sales Guidance

Bearing systems are crucial to the efficiency and longevity of machinery across various industries. According to a report by the International Journal of Advanced Manufacturing Technology, improper maintenance can lead to a 30% reduction in bearing lifespan, highlighting the importance of robust Bearing Maintenance & After-Sales Support. Additionally, a study by the American Wind Energy Association revealed that proper maintenance practices can increase the operational lifespan of bearings in wind turbines by up to 25%, significantly reducing downtime and repair costs. This underscores the necessity for organizations to implement optimal bearing maintenance strategies while ensuring exceptional after-sales support is available to navigate the complexities of bearing technology. In this blog, we will explore effective solutions for enhancing bearing longevity and the critical role that after-sales guidance plays in achieving these goals.

Maximizing Bearing Lifespan Through Proper Maintenance Practices

Maximizing the lifespan of bearings is crucial for maintaining the efficiency and reliability of machinery. Proper maintenance practices play a key role in achieving this goal. One of the fundamental steps is regular inspection, which allows for the early detection of wear and potential failures. Monitoring factors such as temperature, vibration, and lubrication levels can provide valuable insights into the bearing's condition. By implementing a predictive maintenance schedule, operators can plan interventions before minor issues escalate into costly downtimes.

Additionally, the selection of appropriate lubricants significantly impacts bearing performance. Using the right type and amount of lubricant not only reduces friction but also prevents corrosion and wear. It's essential to adhere to the manufacturer's recommendations regarding lubricant intervals and quantities, ensuring that the bearings operate smoothly under varying load conditions. Furthermore, providing training for personnel involved in maintenance can enhance their understanding of best practices and help maintain consistency in maintenance routines, ultimately extending the life of the bearings.

Innovative Technologies for Enhanced Bearing Performance

In today's fast-paced industrial landscape, the demand for enhanced bearing performance is more critical than ever. Innovative technologies are driving this transformation, enabling manufacturers to develop bearings that not only meet but exceed industry standards. According to a recent report by Smithers, the global bearing market is projected to reach $100 billion by 2025, with significant advancements in materials and design. These innovations include ceramic and hybrid bearings, which offer lower friction and improved durability compared to traditional steel options.

Tip 1: Regularly monitor bearing temperatures during operation, as overheating can lead to premature failure. Implementing temperature sensors can provide real-time data and early warnings for maintenance needs.

Advanced lubrication systems are also crucial to prolong bearing longevity. Automated lubrication solutions ensure that bearings receive the right amount of lubricant at optimal intervals, reducing wear and extending service life. A study by the National Lubricating Grease Institute indicates that proper lubrication can increase bearing lifespan by up to 50%.

Tip 2: Conduct routine audits of your lubrication practices to identify areas for improvement, which can lead to significant cost savings in maintenance and replacements. Investing in the latest bearing technologies and maintenance practices will not only enhance performance but also lead to exceptional after-sales guidance, ensuring customers receive the best support throughout the product's lifecycle.

Understanding Load Conditions for Optimal Bearing Selection

When it comes to selecting the right bearings for your application, understanding load conditions is paramount. Bearings are integral components in various machinery and equipment, and their performance heavily relies on correctly matching them to the specific load they will encounter. Load conditions can be categorized into static and dynamic loads, with each type requiring a different approach to selection. For example, a bearing subjected to constant static loads may perform well if designed for high radial loads, while one that frequently experiences varying dynamic loads may need to accommodate changes in both axial and radial pressures.

Furthermore, it is crucial to consider factors such as the magnitude of the load, the speed of operation, and environmental conditions when making your selection. Each of these elements influences the bearing's material choice, size, and design. For instance, a bearing operating in high-temperature environments may require special materials that can withstand thermal expansion and resist wear. By thoroughly analyzing load conditions and their implications, you can ensure optimal bearing longevity and reliability, enhancing overall machinery performance and reducing the likelihood of premature failure.

Load Conditions and Bearing Selection Impact

This chart illustrates the relationship between different load conditions and the impact on bearing selection, emphasizing the importance of understanding load scenarios for optimal bearing longevity and effective after-sales guidance.

Effective After-Sales Support: Building Long-Term Customer Relationships

In today's competitive market, effective after-sales support is crucial for fostering long-term customer relationships. A 2021 report by the Service Council indicated that companies prioritizing robust customer support experiences can see a 33% increase in customer retention rates. This illustrates that providing thorough guidance and support post-purchase not only enhances the customer experience but also boosts loyalty, leading to repeat business.

Moreover, the bearing industry has seen firsthand how exceptional after-sales support can elevate brand reputation. According to a 2022 analysis by Research and Markets, a staggering 70% of customers are more likely to recommend a company with excellent after-sales service to their peers. This creates a ripple effect—satisfied customers directly contribute to positive word-of-mouth, ultimately expanding the company's reach and market share. By investing in comprehensive after-sales strategies, businesses can ensure their bearings not only perform optimally but also maintain enduring customer relationships that stand the test of time.

Common Bearing Issues and Proactive Solutions to Avoid Downtime

When it comes to bearing maintenance, understanding common issues is crucial for ensuring operational efficiency and preventing costly downtime. According to a report from the Bearing Specialists Association, approximately 42% of bearing failures are attributed to improper lubrication. Insufficient, contaminated, or excessive lubricant can lead to increased friction and overheating, ultimately damaging the bearing. Regular checks and scheduled relubrication can help mitigate these risks and prolong the lifespan of your bearings.

**Tip:** Always use the manufacturer-recommended lubricant type and adhere to optimal re-lubrication intervals based on operating conditions.

Another prevalent issue is misalignment, which accounts for around 25% of premature bearing failures. Misaligned bearings can lead to uneven loading and accelerated wear, negatively impacting performance. Implementing proper installation procedures and employing alignment tools can greatly reduce this risk. Regular inspections aimed at detecting misalignment early can save both time and resources.

**Tip:** Utilize laser alignment tools for precision and consult alignment standards to maintain accuracy during installation and maintenance.

Solutions for Optimal Bearing Longevity and Exceptional After Sales Guidance - Common Bearing Issues and Proactive Solutions to Avoid Downtime

| Issue |

Symptoms |

Proactive Solution |

After Sales Guidance |

| Insufficient Lubrication |

Overheating, Unusual Noise |

Regular Lubrication Checks |

Provide lubrication schedules |

| Misalignment |

Vibration, Excessive Wear |

Alignment Tools Use |

Post-installation alignment checks |

| Contamination |

Noise, Increased Friction |

Use of Seals and Filters |

Educate on proper handling |

| Overloading |

Deformation, Breakdowns |

Load Monitoring Systems |

Provide loading guidelines |

| Incorrect Installation |

Noise, Early Failures |

Training on Installation |

Provide installation manuals |

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us