Comprehensive Guide to SKF Equivalent Bearings: Key Specifications and Sourcing Tips

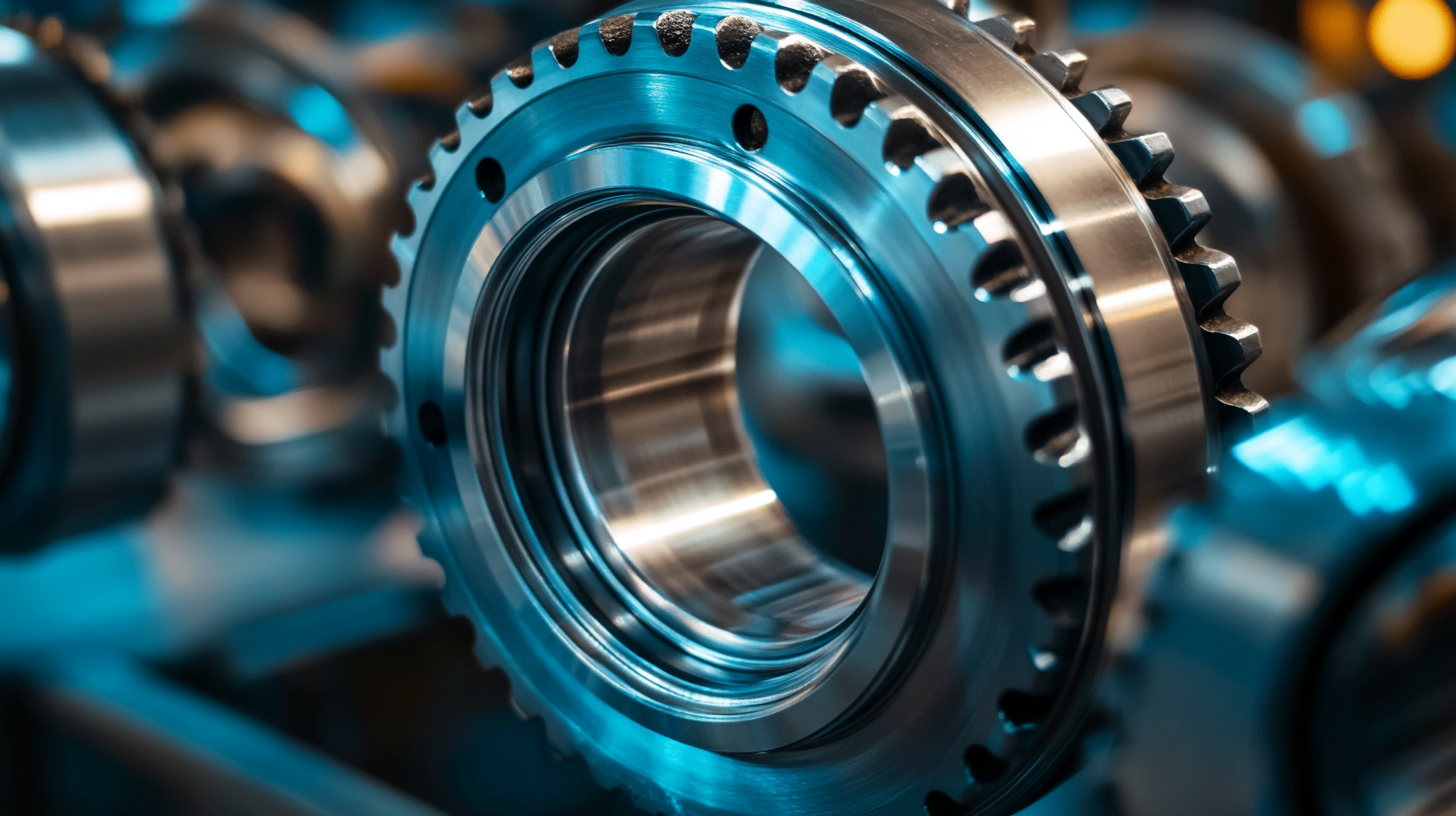

In the realm of mechanical engineering and manufacturing, bearings play a crucial role in ensuring operational efficiency and longevity of machinery. As industries strive for optimized performance, the demand for reliable bearing solutions has surged, focusing attention on SKF equivalent bearings. According to a recent industry report by MarketsandMarkets, the global bearing market is expected to reach $92.9 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.0% from 2020. This increase underscores the growing importance of not just high-quality bearings but also their equivalents, which deliver similar performance at potentially lower costs.

SKF equivalent bearings are designed to match the specifications and performance characteristics of the renowned SKF brand, facilitating an effective balance between quality and affordability. As various sectors including automotive, aerospace, and manufacturing adopt advanced solutions to enhance productivity, sourcing the right equivalent bearings has become instrumental. Industry experts suggest that understanding key specifications—such as load ratings, material properties, and lubrication needs—is essential for making informed decisions. This comprehensive guide provides valuable insights into SKF equivalent bearings, equipping readers with the knowledge they need to navigate the sourcing process effectively.

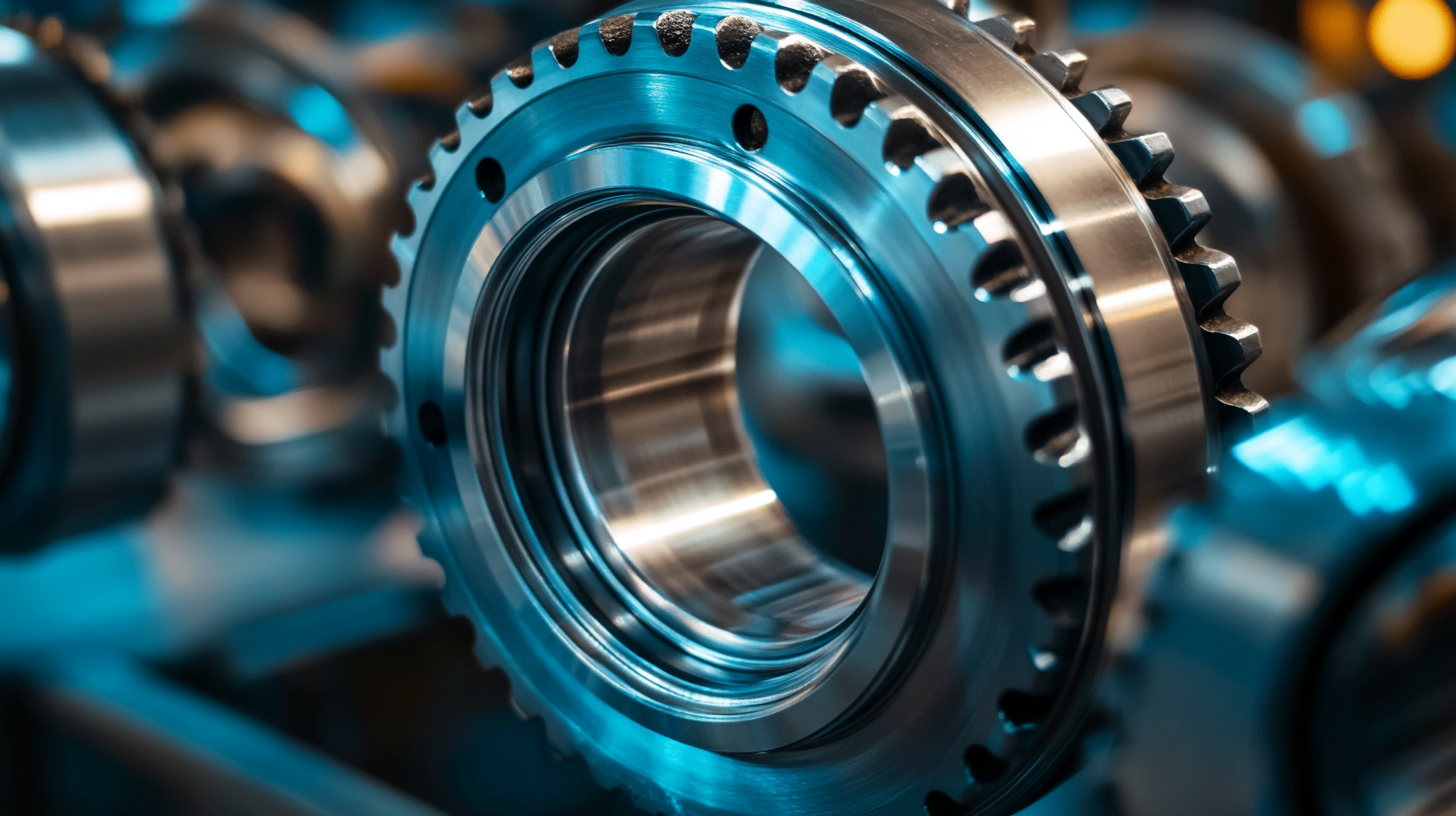

Understanding SKF Bearings: An Overview of Types and Applications

SKF bearings are pivotal components in various industries, known for their reliability and performance. There are several types of SKF bearings, including deep groove ball bearings, spherical roller bearings, and tapered roller bearings. Each type serves specific applications, ranging from automotive and aerospace to heavy machinery and agriculture. According to a report by MarketsandMarkets, the global bearing market is projected to grow from $81.3 billion in 2021 to $115.1 billion by 2026, indicating a significant rise in demand for SKF and other high-quality bearings.

Deep groove ball bearings, one of the most commonly used types, are versatile and can accommodate radial and axial loads in both directions. They are ideal for applications such as electric motors and gearboxes. In contrast, spherical roller bearings are designed for heavy loads and can handle misalignments, making them suitable for industrial machinery and construction equipment. Understanding these distinctions is crucial for industries aiming to optimize their machinery's performance and longevity.

Furthermore, the choice of bearing significantly impacts operational efficiency and maintenance costs. Research from Technavio suggests that a 5% increase in bearing performance can lead to a 15% reduction in energy consumption. Therefore, selecting the right SKF bearing not only enhances equipment reliability but also contributes to cost savings and sustainability in operations. By associating specific applications with the appropriate bearing types, companies can ensure optimal functionality and reduced downtime in their machinery.

Comprehensive Guide to SKF Equivalent Bearings: Key Specifications and Sourcing Tips

| Bearing Type | Description | Key Specifications | Applications |

| Deep Groove Ball Bearing | Versatile bearing suitable for high-speed and heavy-load applications. | Inner Diameter: 20-200mm, Outer Diameter: 42-300mm | Electric motors, pumps, and gearboxes. |

| Angular Contact Bearing | Designed to support both radial and axial loads. | Contact Angle: 15°-40°, Load Capacity: Medium-High | Machine tools, robotics, and automotive applications. |

| Self-Aligning Ball Bearing | Allows for misalignment of shaft and housing. | Inner Diameter: 10-150mm, Outer Diameter: 30-220mm | Agricultural machinery, conveyors, and fans. |

| Tapered Roller Bearing | Used for heavy loads and can handle significant thrust loads. | Inner Diameter: 30-250mm, Outer Diameter: 50-320mm | Automotive wheel hubs, heavy machinery, and trailers. |

| Needle Roller Bearing | Compact design that can handle high loads with limited space. | Width: 10-30mm, Load Capacity: High | Motorcycle transmissions, automotive components, and construction equipment. |

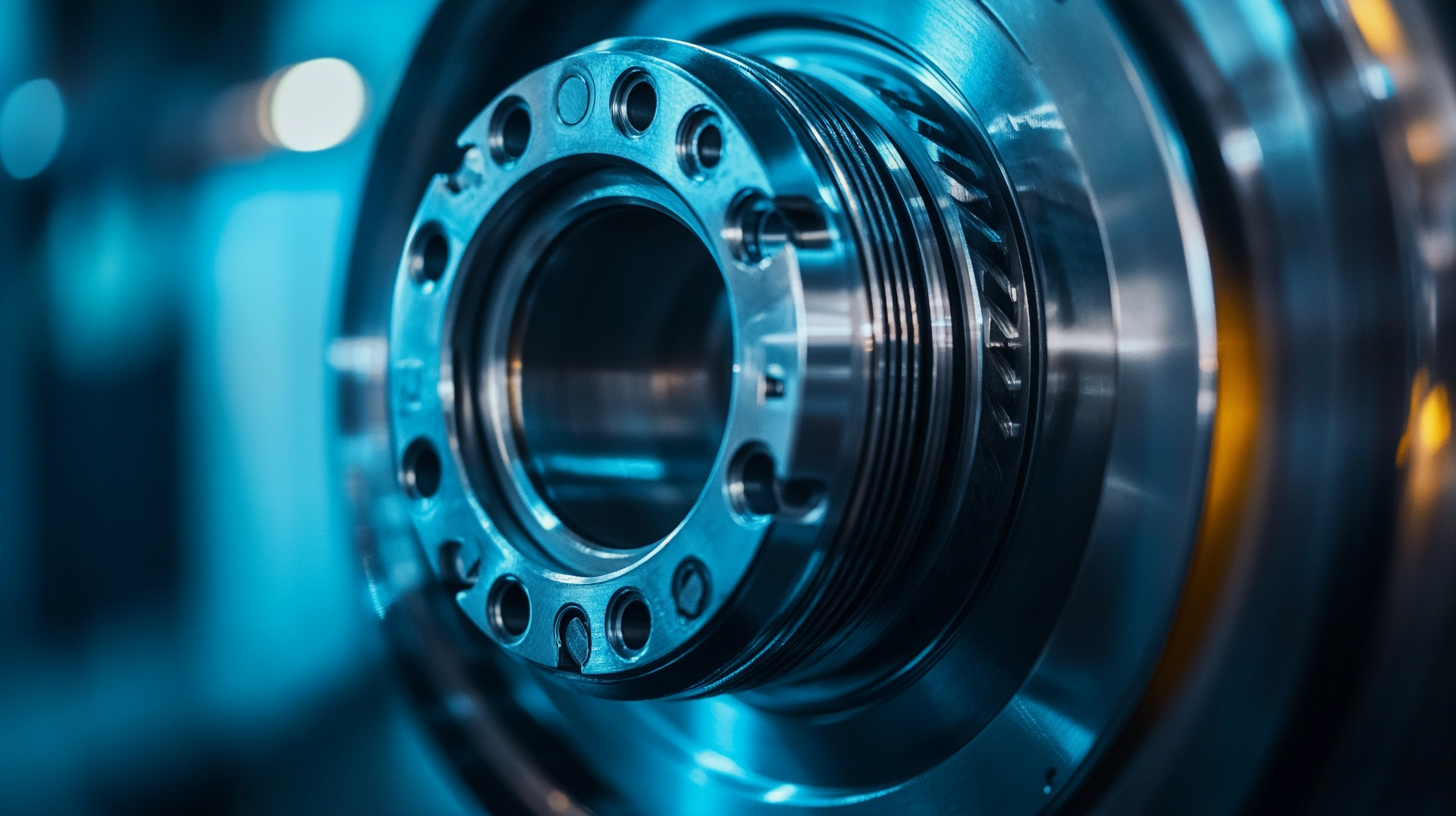

Key Specifications to Consider When Selecting SKF Equivalent Bearings

When selecting SKF equivalent bearings, it’s crucial to consider several key specifications that can significantly impact performance and longevity. The first factor is the bearing's physical dimensions, particularly the outside diameter and width. These measurements are essential not just for ensuring proper fit within equipment, but also for calculating the correct grease quantity and frequency of application. Adequate lubrication, tailored to the specific operational context, can markedly enhance bearing life and operational reliability, reducing the risk of unscheduled downtime.

Another critical specification is the load rating of the bearing, which indicates its capacity to withstand various types of loads without failure. This includes static load ratings, dynamic load ratings, and the bearing's ability to handle shock loads that may occur during operation. Additionally, examining the materials used in the construction of the bearings is vital—different materials may offer varying resistance to corrosion, wear, and heat, all of which can affect performance in specific environments.

Furthermore, sourcing tips play an important role in selection. It's advisable to work with reputable suppliers who can provide verified equivalent products that meet or exceed original equipment specifications. Understanding the specifics of the application and aligning them with the bearing's specifications ensures optimal performance, making the bearing selection process an integral part of maintaining efficient machinery operations.

SKF Equivalent Bearings Specifications Comparison

Sourcing Tips: Where and How to Find Reliable SKF Alternatives

When it comes to sourcing SKF equivalent bearings, it's essential to employ strategic practices to ensure you find reliable alternatives. Start by identifying reputable suppliers who specialize in bearing manufacturing and distribution. Look for companies that have a proven track record in the industry and offer rigorous quality control measures. Utilizing platforms that showcase reviews and ratings can also help in assessing the reliability of these suppliers.

Furthermore, consider reaching out to industry professionals or participating in forums dedicated to bearing solutions. Engaging with others who have faced similar sourcing challenges can yield valuable insights into trustworthy alternatives. Pay attention to companies that emphasize value-based pricing strategies, as highlighted in recent discussions within the industry. This approach can guide you in understanding the inherent value of the products you are considering, rather than solely focusing on the price tag.

When evaluating potential SKF equivalent bearings, ensure that you check for essential specifications that align with your application's requirements. Request detailed product information, such as material composition, load ratings, and dimensional accuracy, to validate the quality of the alternatives you are considering. By taking these proactive steps, you can confidently navigate the sourcing process and find SKF alternatives that meet your performance expectations.

SKF Equivalent Bearings Market Share

This pie chart illustrates the market share of various bearing brands, highlighting the dominance of SKF bearings compared to their equivalents. The data indicates that SKF holds a significant portion of the market, followed by other competitors like NSK and FAG.

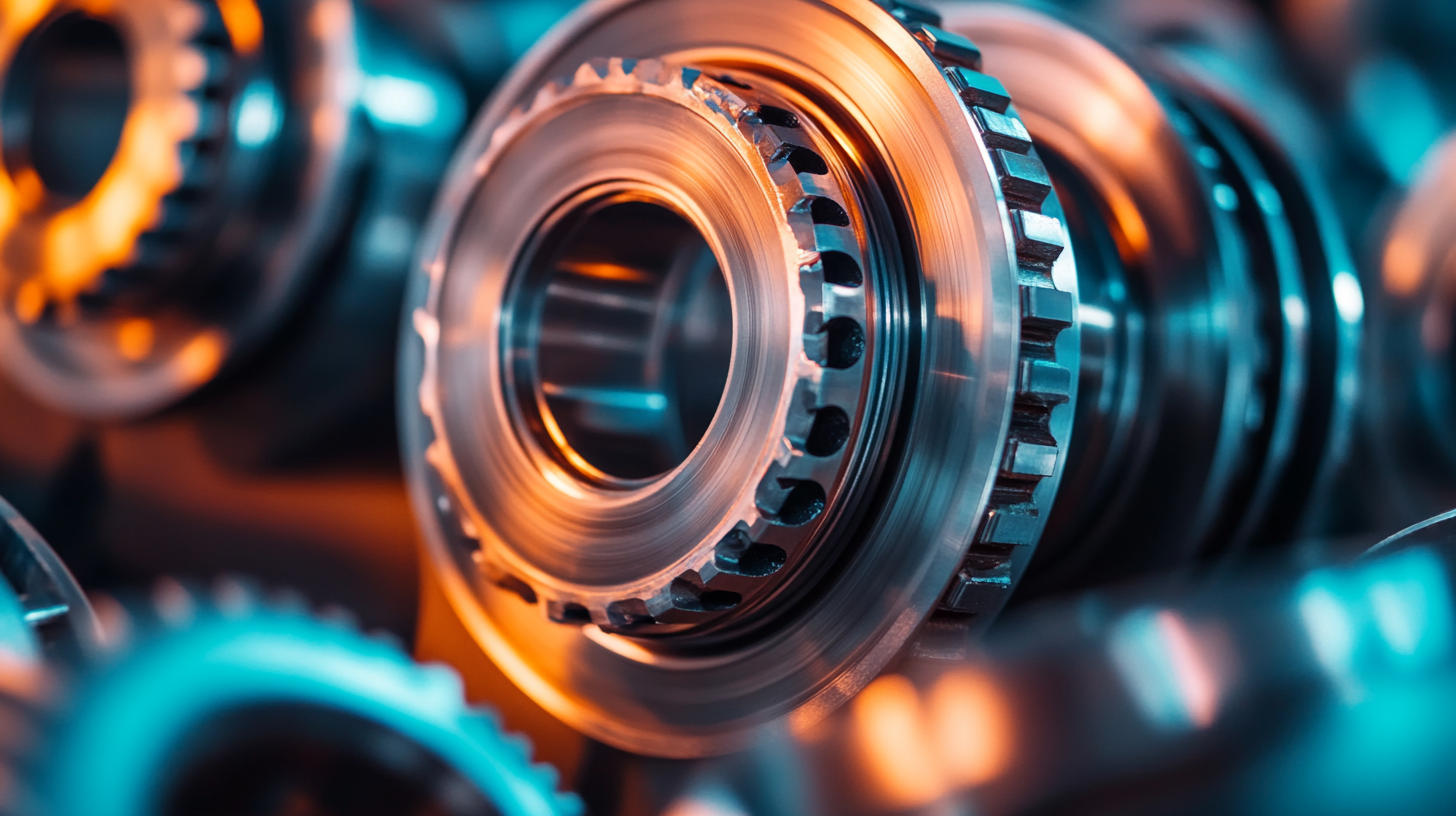

Comparative Analysis: SKF Bearings vs. Their Equivalents

When comparing SKF bearings to their equivalents, it's essential to understand the key specifications that can significantly affect performance and durability. SKF is renowned for its rigorous quality standards and extensive testing protocols, which often set a benchmark in the bearing industry. However, not all applications require the premium features of SKF products, and there are equivalent bearings that may serve as cost-effective alternatives without compromising on quality.

A critical aspect to consider is the operational conditions and the environment in which the bearings will be used. For instance, while SKF bearings provide high reliability under extreme conditions, some equivalent brands also offer good performance ratings that can meet standard operational demands. Evaluating factors such as load capacity, speed ratings, and temperature range can help in identifying a suitable alternative. Moreover, understanding the materials used in the construction of both SKF and equivalent bearings can shed light on their wear resistance and lifespan, helping you make a more informed choice.

Sourcing equivalent bearings can sometimes be a daunting task, especially with numerous brands and specifications available in the market. It's advisable to consult with suppliers who have a good reputation for quality assurance and customer service. Additionally, obtaining samples and reviewing technical datasheets can provide crucial insights into the performance comparisons between SKF bearings and equivalents. By leveraging comprehensive research and analysis, you can secure the right bearings for your application while optimizing your budget.

Maintenance and Performance: Best Practices for SKF Equivalent Bearings

When it comes to maintaining SKF equivalent bearings, adherence to best practices is essential for optimal performance and longevity. Regular maintenance routines, including routine inspections and proper lubrication, can significantly reduce wear and tear while enhancing the efficiency of the bearings. It's crucial to monitor for any signs of unusual noises or vibrations, as these can indicate underlying issues that may require immediate attention.

Additionally, understanding the operating environment is vital. Factors such as temperature fluctuations, dust, and moisture levels can impact bearing performance. Employing effective sealing solutions can help protect against contaminants while ensuring that the lubrication remains effective. Using the proper type of lubricant in the right amounts is also key; over or under-lubrication can lead to increased friction and premature failure.

Finally, selecting the correct SKF equivalent bearing based on the specific application is paramount. Consider load capacities, speed ratings, and installation requirements when sourcing replacements. This tailored approach not only enhances performance but also extends the service life of the bearings, ensuring reliable operation throughout their lifecycle. Implementing these best practices will help in achieving peak performance and maintaining the integrity of SKF equivalent bearings in any mechanical system.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us