27 Strategies for Choosing Energy Efficient Bearings for Optimal Performance

In today's fast-paced industrial landscape, the importance of energy efficiency cannot be overstated, especially when it comes to the selection of bearings. The right bearings not only enhance the performance and longevity of machinery but also contribute to significant energy savings over time. This blog, titled "27 Strategies for Choosing Energy Efficient Bearings for Optimal Performance," serves as a comprehensive Energy-Efficient Bearing Selection Guide aimed at assisting engineers and maintenance professionals in making well-informed decisions. By implementing these 27 strategic tips, you can optimize the performance of your equipment while minimizing energy consumption and operational costs. Each strategy focuses on key factors such as material selection, design considerations, and maintenance practices that play a crucial role in achieving maximum energy efficiency. Join us on this journey to discover the essential strategies that will lead to smarter bearing choices and enhance overall productivity.

Understanding the Importance of Energy Efficiency in Bearing Selection

Energy efficiency has become a critical factor in the selection of bearings for various applications, especially as industries strive to reduce operational costs and environmental impacts. Understanding the importance of energy-efficient bearings can lead to significant improvements in overall performance. Recent trends highlight how innovations in bearing design and materials are addressing friction losses, which constitute a considerable portion of energy consumption in machinery. For instance, the adoption of advanced materials in the development of ball bearings is projected to enhance market growth, anticipated to reach USD 33.24 billion by 2032.

When selecting energy-efficient bearings, consider the following tips: First, assess the bearing's friction characteristics to minimize energy losses. For instance, studies have shown that redesigned ball bearings can lead to substantial energy savings without compromising performance. Second, evaluate the compatibility of bearing materials with operating environments to ensure longevity and efficiency. Lastly, keep abreast of technological advancements, as emerging trends in the industry will provide insights into sustainable practices that can optimize energy usage.

By focusing on energy efficiency in bearing selection, manufacturers can not only improve performance but also contribute to more sustainable production processes, reflecting the ongoing innovations in energy-efficient materials across multiple sectors.

Key Factors Influencing the Energy Efficiency of Bearings

When selecting energy-efficient bearings, several key factors come into play that can significantly influence their performance. The material composition of the bearing, for instance, plays a crucial role. High-quality materials such as ceramics or advanced polymers can reduce friction and enhance overall performance, leading to lower energy consumption. Additionally, the bearing’s lubrication type is vital; opting for synthetic lubricants can decrease viscosity and improve energy efficiency.

Tip: Always consider the operating conditions when choosing lubricants. Ensure they are suitable for temperature ranges and environmental factors to maintain optimal performance.

Another important factor is the bearing design. Precision-engineered bearings that minimize gaps and misalignments can greatly enhance efficiency. Ball bearings, for example, often offer lower friction compared to sleeve bearings, making them a preferred choice for energy-saving applications.

Tip: Regular maintenance and monitoring of bearing health can preemptively identify issues that may escalate energy loss, allowing for timely interventions and prolonged bearing lifespan. By focusing on these elements, you can ensure that your bearings provide the best energy efficiency and performance.

Types of Energy Efficient Bearings: A Comprehensive Overview

When it comes to enhancing energy efficiency in machinery, the choice of bearings plays a pivotal role. Energy efficient bearings come in various types, each designed to minimize friction and wear, ultimately leading to improved performance. According to a report by the American Bearing Manufacturers Association (ABMA), approximately 30% of energy loss in industrial applications can be attributed to bearing friction. This statistic underscores the importance of selecting the right type of bearing for optimal energy savings.

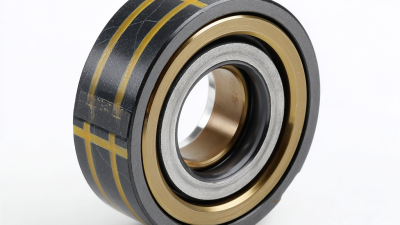

Among the most common types of energy efficient bearings are ceramic hybrid bearings, which combine ceramic balls with metal races. These bearings exhibit significantly lower friction coefficients, with reductions of 20-30% compared to traditional steel bearings, making them ideal for high-speed applications. Additionally, specialized designs such as integral seals and low-friction coatings can further enhance performance. A study conducted by the National Renewable Energy Laboratory (NREL) found that implementing energy efficient bearings in wind turbine systems can yield energy savings of up to 5%, providing a substantial return on investment for fleet operators looking to enhance sustainability while decreasing operational costs.

Best Practices for Evaluating Bearing Performance Metrics

When it comes to selecting energy-efficient bearings, understanding performance metrics is crucial for ensuring optimal functionality in various applications. One of the primary metrics to evaluate is the rolling resistance of the bearings. Lower rolling resistance typically means reduced energy consumption, which is essential for applications where energy efficiency is a priority. When comparing different bearing options, it is vital to assess their coefficients of friction and how these impact overall system efficiency.

Another key performance metric to consider is the load capacity of the bearings. Selecting a bearing that can accommodate the operational load while maintaining durability under varying conditions can lead to significant gains in performance. Additionally, examining the bearing's operational speed rating will help in determining if it aligns with your application's requirements. High-quality bearings designed for energy efficiency often provide enhanced longevity, which further contributes to reduced operational costs over time. By focusing on these performance metrics, businesses can make informed decisions that not only boost productivity but also align with sustainability goals.

Innovative Technologies Enhancing Energy Efficiency in Bearings

Innovative technologies are transforming the field of bearing design and production, significantly enhancing energy efficiency. One of the key developments is the use of advanced materials, such as hybrid ceramic and high-performance polymers. These materials not only reduce friction but also improve durability and temperature resistance, allowing bearings to operate optimally under varied conditions. Consequently, the maintenance cycles can be extended, leading to reduced downtime and overall operational costs.

Additionally, smart manufacturing techniques, including 3D printing and precision machining, are enabling the creation of customized bearings that precisely match the requirements of specific applications. These tailored solutions minimize energy loss during operation and enhance overall system efficiency. Furthermore, the incorporation of IoT technology allows for real-time monitoring of bearing performance, facilitating predictive maintenance. By analyzing data from sensors embedded in the bearings, companies can anticipate failures before they occur, optimizing energy use while extending the life of the equipment.

Energy Efficiency in Bearings: Comparison of Strategies

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us