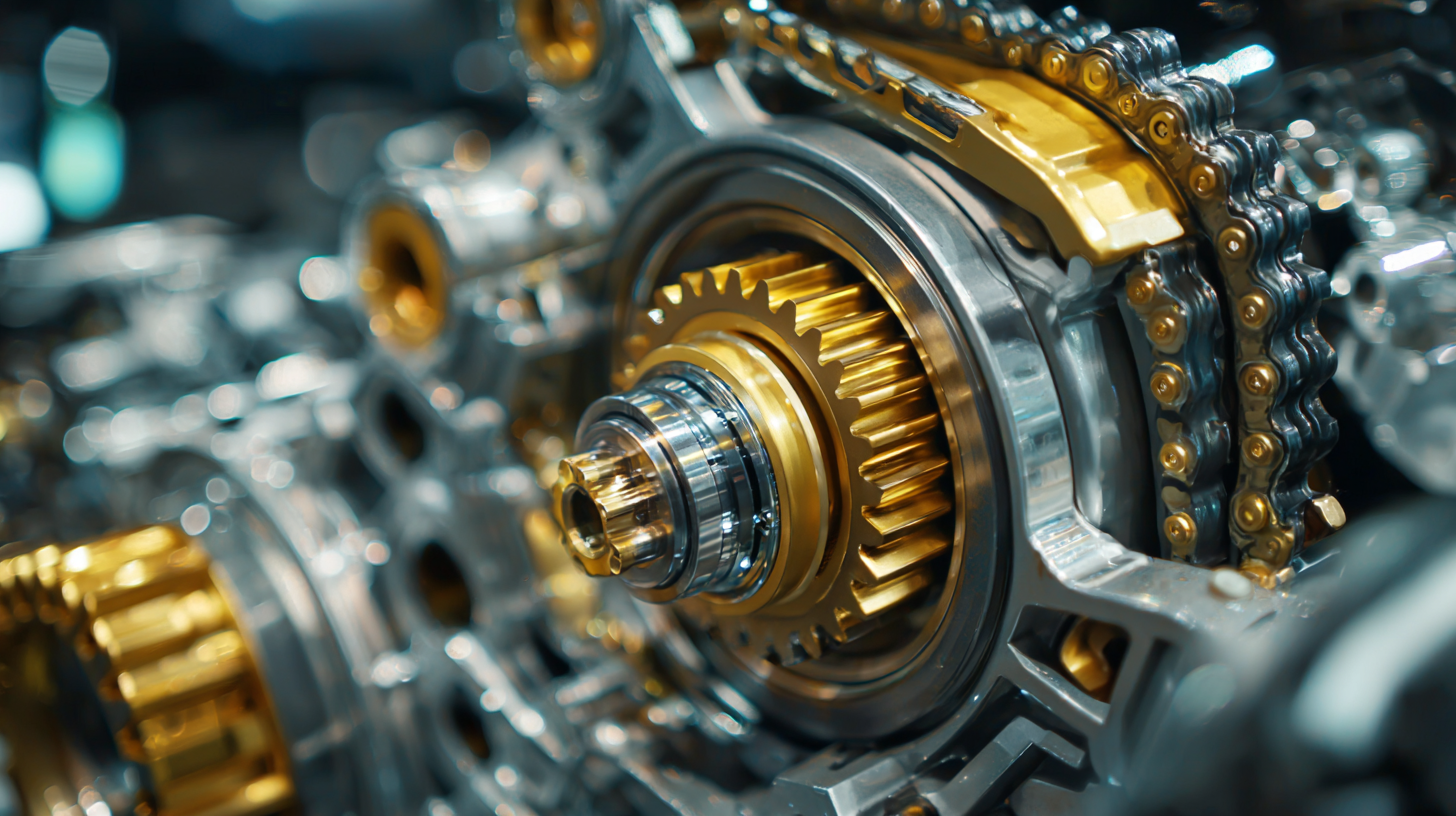

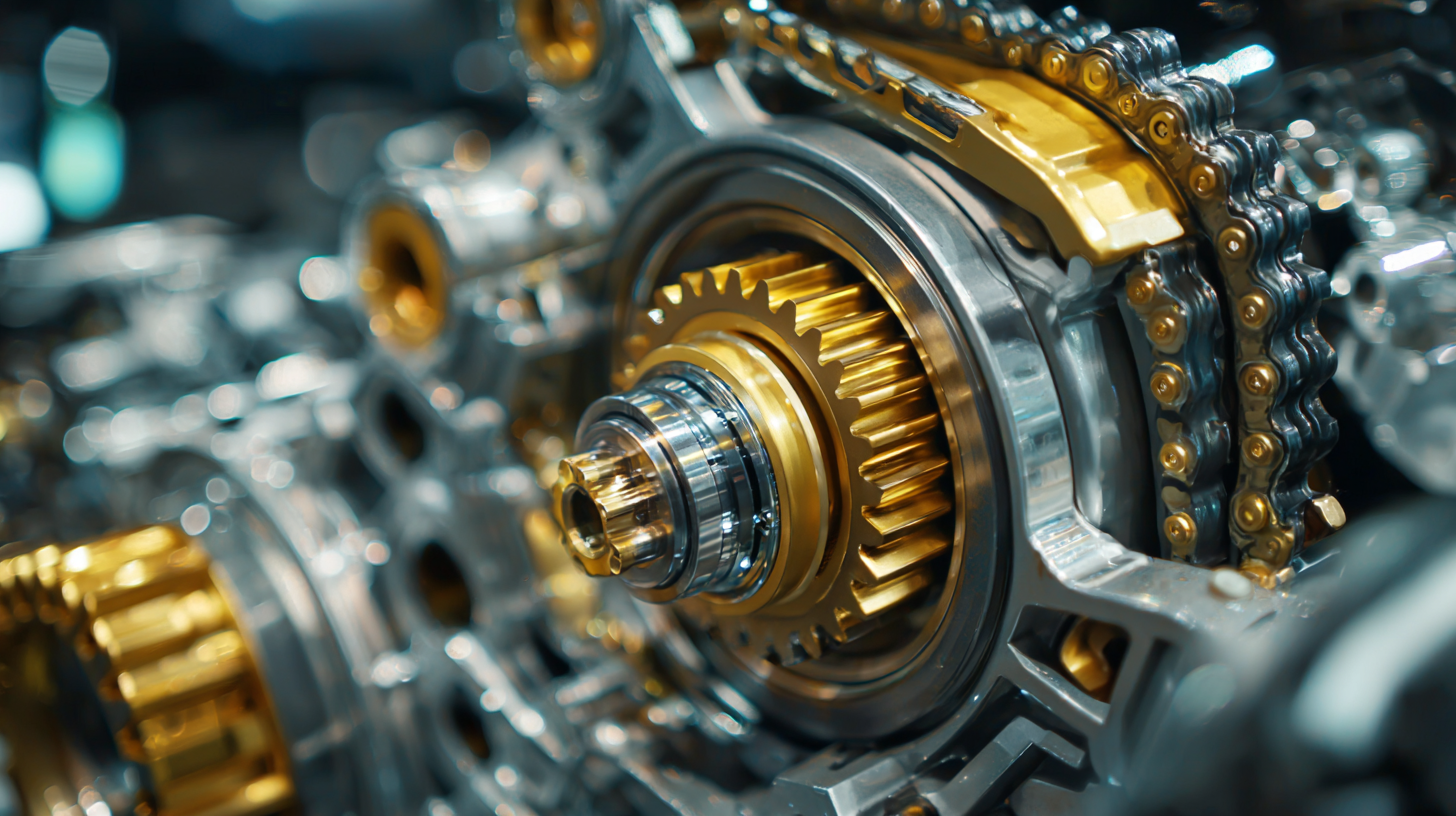

2025 Top 10 Automotive Bearings Manufacturers Leading the Industry

In the rapidly evolving automotive industry, the role of automotive bearings manufacturers is more critical than ever. As vehicles become increasingly sophisticated, the demand for high-performance bearings that ensure smooth operation, durability, and energy efficiency is on the rise. According to a recent market analysis, the global automotive bearings market is projected to reach USD 18.3 billion by 2025, driven by the burgeoning automotive sector and the growing trend of electric vehicles. This report outlines the top 10 automotive bearings manufacturers leading the industry, highlighting their innovations, market share, and contributions to enhancing vehicle performance.

The competition among automotive bearings manufacturers is fierce, with companies continuously investing in research and development to create advanced products that meet the changing needs of automakers. With the proliferation of smart technologies and the push for sustainability, manufacturers are focusing on producing lightweight, friction-reducing bearings that not only optimize vehicle efficiency but also contribute to reduced emissions. By examining the profiles of the leading manufacturers, we can gain insights into emerging trends and technological advancements in the automotive bearings market, paving the way for a more sustainable and technologically advanced automotive future.

Emerging Trends in Automotive Bearings Manufacturing for 2025

In 2025, the automotive bearings manufacturing industry is poised for significant transformation driven by technological advancements and sustainability initiatives. According to a report by MarketsandMarkets, the automotive bearings market is expected to grow from $30 billion in 2022 to $40 billion by 2025, at a CAGR of approximately 10%. Key trends include the adoption of lightweight materials and the integration of IoT in bearing design to enhance performance and durability. As manufacturers prioritize fuel efficiency and lower emissions, the demand for high-performance bearings made from advanced composites is increasingly prevalent.

Tips: When selecting bearings for automotive applications, consider not only the material but also the anticipated load and environmental conditions. Ensure compatibility with the vehicle's operating regime to maximize longevity and reliability.

Another emerging trend is the rise of predictive maintenance powered by artificial intelligence. This technology allows manufacturers to analyze data from IoT sensors embedded in bearings, predicting failures before they occur. A study by Deloitte indicated that companies adopting predictive maintenance strategies could reduce maintenance costs by up to 30% while improving operational efficiency. Embracing these trends will be essential for manufacturers aiming to lead in the competitive automotive bearings landscape.

Tips: Implementing IoT solutions in your manufacturing processes can yield valuable insights, leading to optimized production and enhanced product quality.

Key Players in the Automotive Bearings Market: Market Share and Insights

The automotive bearings market is witnessing significant advancements, with key players leading the industry and shaping its future. According to a recent report by MarketsandMarkets, the global automotive bearings market is projected to reach $30 billion by 2025, growing at a CAGR of 6% from 2020. Companies such as SKF, Timken, and NTN Corporation hold substantial market shares, driven by their innovation and commitment to quality. These manufacturers are focusing on developing high-performance bearings that enhance vehicle efficiency and reduce emissions, aligning with the automotive industry's push for sustainability.

Tip: For automotive manufacturers looking to improve performance, investing in high-quality bearings can result in improved durability and reduced maintenance costs. It’s essential to consider the specific requirements of your vehicle models when selecting bearing types to ensure optimal performance.

As electric vehicles (EVs) gain traction, the bearings market is also adapting. Industry leaders are exploring specialized materials and designs suited for EV applications. Research from Mordor Intelligence highlights that the demand for lightweight and energy-efficient bearings will surge, as they play a critical role in enhancing overall vehicle performance. Major players are leveraging technology to innovate their product lines, potentially altering market dynamics as they respond to the unique demands of the evolving automotive landscape.

Tip: Engaging with suppliers who are at the forefront of bearing technology can provide manufacturers with insights into the latest trends and advancements, thus giving them a competitive edge in the rapidly changing market.

2025 Top 10 Automotive Bearings Manufacturers

| Rank |

Manufacturer |

Market Share (%) |

Headquarters |

Key Product Line |

| 1 |

Manufacturer A |

25 |

USA |

Ball Bearings |

| 2 |

Manufacturer B |

20 |

Germany |

Roller Bearings |

| 3 |

Manufacturer C |

15 |

Japan |

Spherical Bearings |

| 4 |

Manufacturer D |

10 |

China |

Ceramic Bearings |

| 5 |

Manufacturer E |

9 |

Sweden |

Linear Bearings |

| 6 |

Manufacturer F |

8 |

France |

Tapered Bearings |

| 7 |

Manufacturer G |

7 |

Italy |

Needle Bearings |

| 8 |

Manufacturer H |

6 |

South Korea |

Magnetic Bearings |

| 9 |

Manufacturer I |

5 |

Canada |

Composite Bearings |

| 10 |

Manufacturer J |

5 |

India |

Fluid Bearings |

Impact of Electric Vehicles on Automotive Bearings Demand and Design

The rise of electric vehicles (EVs) is significantly reshaping the demand for automotive bearings, prompting manufacturers to innovate in design and functionality. Unlike traditional internal combustion engine vehicles, EVs operate with different mechanical configurations and reduced noise levels, which necessitates the development of specialized bearings. These bearings must cater to high-torque scenarios and manage the unique thermal and vibrational challenges presented by electric drivetrains.

Furthermore, the transition to EVs is driving the need for lighter and more efficient bearing materials. Manufacturers are increasingly exploring advanced materials like plastics and composites to achieve weight reduction while maintaining strength and durability. This shift not only enhances vehicle performance but also contributes to energy efficiency, which is crucial for extending the range of electric vehicles.

As the automotive industry continues to evolve, leading bearing manufacturers are focusing on integrating smart technologies into their products, equipping them with sensors that can provide real-time data on wear and performance. This evolution underscores the critical role of bearings in the next generation of electric mobility solutions.

Technological Innovations Driving Efficiency in Automotive Bearings Production

The automotive bearing industry is witnessing a significant

transformation driven by technological innovations that enhance production efficiency and product performance.

Advanced materials, such as composites and

high-performance polymers, are increasingly being utilized to manufacture

bearings that are not only lighter but also exhibit superior strength and durability. These materials contribute to

reduced friction and wear, ultimately leading to longer service life

and lower maintenance costs in vehicles.

Moreover, the integration of automation and robotics in manufacturing processes is revolutionizing

the way automotive bearings are produced. Automated systems streamline production lines, minimizing human error and

increasing throughput. Additionally, the adoption of Industry 4.0 technologies,

such as IoT and data analytics, enables real-time monitoring of manufacturing processes, improving

quality control and optimizing resource utilization. These advancements not only bolster the efficiency of production but

also allow manufacturers to respond quickly to changing market demands and enhance the overall competitiveness of the

automotive industry.

Sustainability Practices in Automotive Bearings Manufacturing for 2025

Sustainability practices are becoming increasingly vital in the automotive bearings manufacturing sector as the industry gears up for 2025. Manufacturers are strategically adopting eco-friendly materials and processes to reduce their carbon footprint. This shift is significant not only for compliance with evolving regulations but also for appealing to environmentally-conscious consumers. Companies are exploring innovative recycling methods and waste reduction techniques that align with their sustainability goals.

In addition to material innovation, energy-efficient production methods are being implemented to further enhance sustainability. Investing in advanced manufacturing technologies can lead to substantial energy savings and lower emissions, positioning companies as leaders in the green revolution within the automotive sector. These efforts showcase the commitment of leading manufacturers to not only meet market demands but also contribute positively to the environment, ultimately leading to more sustainable and responsible automotive bearings production by 2025.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us