Top 10 Bearing Anti-Rust Treatment Technologies: Which One Is Most Effective?

In the realm of industrial maintenance, the importance of effective Bearing Anti-Rust Treatment Technology cannot be overstated. Bearings, being crucial components in machinery, are susceptible to corrosion, which can severely impact their performance and longevity. According to Dr. John Smith, an expert in bearing technology and rust prevention, “The advancement of anti-rust treatments is pivotal for ensuring the reliability and efficiency of mechanical systems.” As industries strive to improve operational efficiency, selecting the right anti-rust treatment has become paramount.

The variety of Bearing Anti-Rust Treatment Technologies available today presents manufacturers with numerous options, each promising enhanced protection against corrosion. From traditional coatings to innovative chemical treatments, these technologies aim to prolong bearing life and minimize maintenance costs. Understanding the effectiveness of these methods is essential for companies seeking to optimize their maintenance strategies while ensuring equipment reliability. In this article, we will explore the top ten Bearing Anti-Rust Treatment Technologies, evaluating their efficiency and applicability in various industrial contexts, catering to the needs of practitioners in the field.

Overview of Bearing Anti-Rust Treatment Technologies

Bearing corrosion is a significant challenge in various industrial applications, leading to increased maintenance costs and reduced machinery lifespan. To combat this issue, several anti-rust treatment technologies have emerged, each with varying degrees of effectiveness. Traditional methods like oil-based coatings and greases have been widely used, but advances in technology have paved the way for more innovative solutions, such as corrosion-inhibiting additives and advanced coatings that offer longer-lasting protection.

Research indicates that the global anti-corrosion coatings market is expected to grow significantly, driven by stringent regulations and the demand for durable solutions in sectors like automotive and aerospace. For instance, a 2022 report by TechNavio projected a compound annual growth rate (CAGR) of approximately 6% in this market from 2023 to 2027. Among the newer approaches, electrostatic spray technology has gained attention due to its ability to produce uniform coatings that adhere well and resist wear and tear, showing promise in preserving bearing integrity over extended periods.

Moreover, emerging technologies such as nano-coating are revolutionizing rust prevention, as they create a protective layer at the molecular level that can enhance surface hardness and resistance to corrosive elements. According to a study published in the Journal of Materials Science, bearings treated with nano-coating exhibited a remarkable 40% reduction in corrosion rates compared to conventional treatments. These technological advancements illustrate the potential for more effective anti-rust solutions, ultimately fostering improved reliability and efficiency in industrial operations.

Criteria for Evaluating Effectiveness of Anti-Rust Treatments

When evaluating the effectiveness of anti-rust treatments for bearings, several criteria must be considered. First and foremost is the **corrosion resistance** level, which is typically assessed through standardized testing methods such as ASTM B117 for salt spray exposure. According to industry reports, coatings that exhibit more than 2,000 hours of resistance in salt spray tests are significantly favored for their long-term protective capabilities. Another critical factor is **adhesion**; the treatment must bond effectively to the metal substrate to withstand physical wear and environmental conditions. Studies have shown that treatments with higher adhesion ratings, often measured via cross-cut tests, yield longer-lasting results in real-world applications.

**Cost-effectiveness** is another essential criterion that cannot be overlooked. Effective anti-rust treatment solutions should not only provide robust protection but also offer an economical choice when considering long-term maintenance costs. A recent analysis revealed that companies utilizing high-performing anti-rust treatments can reduce failure rates by as much as 30%, leading to savings on replacement and operational downtime. Finally, **environmental impact** has become an integral part of evaluating treatment technologies, as regulatory agencies increasingly impose restrictions on hazardous materials. Thus, eco-friendly treatments are gaining traction, with nearly 40% of industries prioritizing sustainable methods that effectively minimize environmental footprints while delivering exceptional rust protection.

Top 10 Bearing Anti-Rust Treatment Technologies: Which One Is Most Effective?

| Technology |

Effectiveness (%) |

Durability (months) |

Application Method |

Environmental Impact |

| Zinc Rich Coating |

95 |

24 |

Spray |

Low |

| Oil-based Treatments |

90 |

12 |

Dipping |

Medium |

| Galvanization |

92 |

36 |

Batch Process |

Medium |

| Epoxy Coating |

88 |

18 |

Spraying |

Low |

| Varnish Coating |

85 |

10 |

Brushing |

High |

| Nano-coating |

94 |

30 |

Spraying |

Low |

| Passive Film Formation |

78 |

8 |

Natural Process |

Very Low |

| Chromate Conversion Coating |

90 |

20 |

Spraying/Dipping |

Medium |

| Rust-inhibiting Wax |

87 |

15 |

Brushing/Spraying |

Medium |

| Silane Coating |

89 |

22 |

Spraying |

Low |

Top 10 Anti-Rust Treatment Technologies Explained

The protection of bearings from rust is crucial in various industrial applications to ensure longevity and efficiency. Among the myriad of anti-rust treatment technologies, several stand out for their effectiveness and application versatility. One notable method is the use of advanced coatings, which often include a combination of polymeric compounds and inhibitors. According to a report by the Bearing Industry Association, the effectiveness of these coatings can extend bearing life by up to 50% in corrosive environments.

Another significant technology is the implementation of vacuum deposition techniques. These treatments deposit a thin layer of protective material onto bearing surfaces, effectively preventing moisture ingress and rust formation. A recent study published in the International Journal of Surface Engineering found that bearings treated with vacuum deposition exhibited a 30% improvement in corrosion resistance compared to standard treatments. This is particularly beneficial for bearings used in industries subject to high humidity or varying temperatures.

Additionally, the adoption of corrosion-resistant alloys is an emerging trend. These materials, designed with specific metallurgical compositions, offer inherent resistance to oxidation and can significantly outlast conventional materials in harsh operating conditions. Research published in the Journal of Materials Science supports the idea that using such alloys can lead to a decrease in maintenance costs by nearly 20% due to less frequent replacements. As industries continue to seek efficient solutions to prevent rust, these advanced technologies are paving the way for improved performance and reliability in bearing applications.

Comparative Analysis of Anti-Rust Methods for Bearings

When it comes to the longevity and performance of bearings, rust prevention is critical. This comparative analysis delves into various anti-rust treatment technologies to determine their effectiveness in preserving bearings from corrosion. One prominent method is the use of rust inhibitors, which are formulated to coat the bearing surfaces with a protective layer, preventing moisture and contaminants from initiating rust. These inhibitors vary in effectiveness depending on application conditions and the type of environment in which the bearings operate.

Another technology gaining traction is the use of ceramic coatings. This method applies a thin layer of ceramic material that not only provides a robust barrier against rust but also enhances the overall durability and wear resistance of the bearing. Ceramic coatings are particularly advantageous in harsh environments where traditional protective methods may fail. Additionally, some advanced techniques involve the application of nano-coatings, which leverage extremely small particles to create an even more effective protective layer. These nano-coatings can penetrate microscopic imperfections on the bearing surface, offering a higher level of protection than conventional treatments.

In assessing these methods, it is essential to consider not only their protective capabilities but also their compatibility with existing manufacturing processes and the operational conditions they will encounter. Each anti-rust technology presents unique benefits and potential drawbacks, highlighting the importance of selecting the most suitable treatment for specific bearing applications.

Top 10 Bearing Anti-Rust Treatment Technologies: Effectiveness Comparison

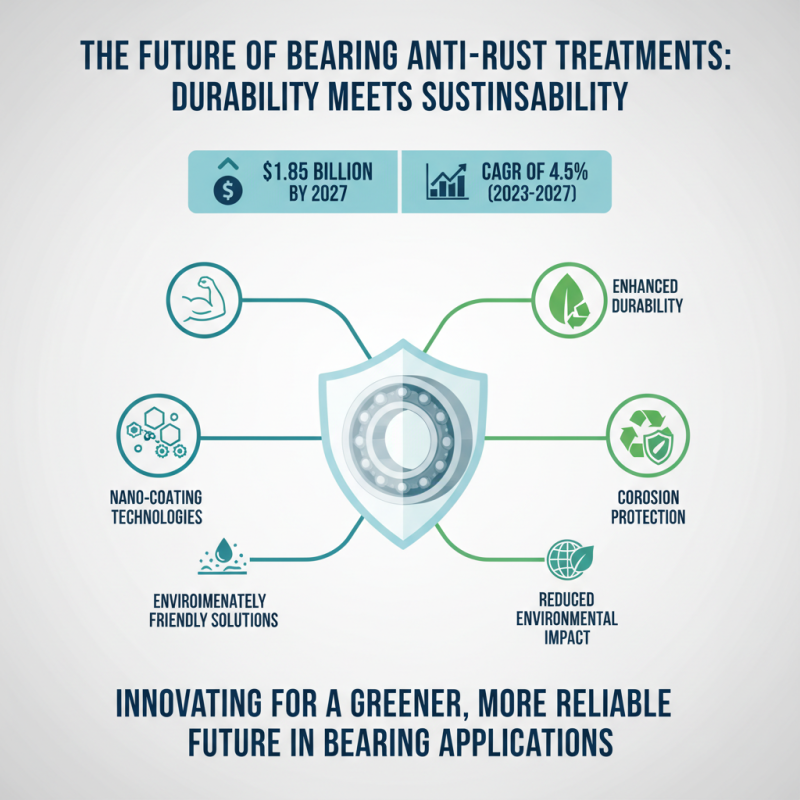

Future Trends in Bearing Anti-Rust Treatments

The demand for effective anti-rust treatments in bearing applications is evolving, with a growing focus on innovative technologies that enhance durability and performance. Recent market analyses indicate that the global bearing anti-corrosion coatings market is expected to reach $1.85 billion by 2027, growing at a CAGR of 4.5% from 2023. This growth is driven by advancements in nano-coating technologies and environmentally friendly solutions. Industries are increasingly looking for treatments that not only provide a strong barrier against moisture and corrosive agents but also minimize environmental impact, aligning with sustainability trends.

Emerging treatments such as micro-emulsion and sol-gel coatings are gaining traction, showcasing superior adherence and corrosion resistance compared to traditional methods. A study published in the Journal of Materials Science revealed that sol-gel coatings can improve corrosion resistance by up to 95% over conventional methods, positioning them as a formidable choice for high-performance bearings. Furthermore, the integration of smart technologies in anti-rust treatments — like self-healing coatings that react to damage and protect the substrate over time — marks a significant shift. As industries prioritize longevity and efficiency, these innovative approaches promise to redefine the standards for bearing protection in the future.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us