Top 10 Tapered Roller Bearings Suppliers You Need to Know About

In the realm of industrial applications, tapered roller bearings play a critical role in enhancing operational efficiency. These bearings are designed to accommodate both radial and axial loads, making them essential components in various machinery, vehicles, and equipment. As a result, the demand for reliable and high-quality tapered roller bearings remains consistently high across multiple industries. However, sourcing the right components can be a daunting task, especially given the myriad of options available today.

To navigate this landscape, it's crucial to identify top-notch tapered roller bearings suppliers that not only meet stringent quality standards but also offer competitive pricing and exceptional customer service. This guide will explore the ten leading suppliers in the market, providing insights into their strengths, product offerings, and unique selling propositions. Whether you're an engineer, procurement specialist, or business owner, understanding the capabilities of these suppliers will empower you to make informed decisions, ensuring that your machinery operates at its peak performance. By focusing on reputable tapered roller bearings suppliers, you can minimize downtime and enhance your operational resilience.

Overview of Tapered Roller Bearings and Their Applications

Tapered roller bearings are essential components in various machinery, designed to accommodate both radial and axial loads. Their unique design features an inner ring with a tapered surface that promotes efficient load distribution and minimizes friction, making them ideal for high-speed applications. Commonly found in automotive systems, industrial machinery, and aerospace engineering, these bearings enhance the performance and reliability of rotating equipment.

The versatility of tapered roller bearings allows them to be utilized in many sectors. In automotive applications, they support wheel hubs and transmission systems, facilitating smooth and efficient operation. In the industrial realm, these bearings contribute to conveyor systems, electric motors, and heavy machinery, ensuring minimal downtime and maintenance. Their ability to handle substantial loads and withstand varying operating conditions makes tapered roller bearings a preferred choice across a wide range of applications, highlighting their significance in modern engineering.

Criteria for Selecting Tapered Roller Bearings Suppliers

When selecting suppliers for tapered roller bearings, several criteria should be taken into account to ensure that the products meet both quality and performance standards. First and foremost, it is crucial to evaluate the supplier's manufacturing capabilities and technology. A company that invests in advanced machinery and adheres to rigorous quality control processes often produces more reliable and durable bearings. Look for suppliers with certifications such as ISO or other relevant industry standards, as these indicate a commitment to maintaining high-quality production practices.

Another important factor is the supplier's experience and expertise in the field. A supplier that has been in the industry for many years typically possesses a deep understanding of the market and technical requirements. This experience can translate into better customer service, support during the selection process, and guidance on proper application of the bearings. Additionally, consider the supplier’s ability to provide customization options, as specific applications might require tailored solutions. Engaging with suppliers who demonstrate a willingness to collaborate and innovate can lead to more efficient, effective outcomes for your projects.

Top 10 Tapered Roller Bearings Suppliers - Performance Metrics

Top 10 Suppliers of Tapered Roller Bearings: A Comparative Analysis

Tapered roller bearings are crucial components in various industrial applications due to their ability to handle radial and axial loads effectively. Several suppliers in the market stand out for their innovative technologies and product reliability. According to a recent industry report by MarketsandMarkets, the global tapered roller bearing market is expected to reach approximately $15.45 billion by 2027, growing at a CAGR of 5.2% from 2020 onwards. This growth highlights the significant demand for high-quality bearings in key sectors like automotive, aerospace, and manufacturing.

When analyzing top suppliers, it is essential to consider not just their product range but also their manufacturing capabilities and commitment to quality assurance. Leading suppliers typically employ advanced manufacturing techniques such as precision forging and surface treatment processes to enhance performance. Industry standards such as ISO 9001:2015 play a vital role in maintaining product quality, ensuring that these suppliers can meet the stringent requirements of their clients.

**Tips:** When selecting a tapered roller bearing supplier, pay attention to their testing methodologies and certification standards. Suppliers who conduct rigorous testing like load and life-cycle assessments are more likely to provide durable and efficient products. Additionally, consider their customer service and support, as prompt assistance can be invaluable when dealing with technical issues or product inquiries. Engaging with suppliers who have a solid reputation in technical support can lead to better long-term partnerships.

Top 10 Tapered Roller Bearings Suppliers You Need to Know About

| Supplier Rank |

Country |

Annual Revenue (Million USD) |

Number of Employees |

Market Share (%) |

Key Industries Served |

| 1 |

USA |

1200 |

3500 |

25 |

Automotive, Aerospace |

| 2 |

Germany |

950 |

2800 |

20 |

Industrial, Marine |

| 3 |

Japan |

780 |

2400 |

15 |

Construction, Mining |

| 4 |

China |

650 |

3000 |

10 |

Heavy Equipment, Automotive |

| 5 |

India |

550 |

2200 |

8 |

Rail, Agriculture |

| 6 |

Italy |

480 |

1800 |

5 |

Packaging, Textile |

| 7 |

South Korea |

430 |

1600 |

4 |

Energy, Machinery |

| 8 |

Brazil |

390 |

1400 |

3 |

Automotive, Transportation |

| 9 |

France |

350 |

1200 |

2 |

Aerospace, Defense |

| 10 |

Russia |

320 |

1000 |

1 |

Oil & Gas, Mining |

Innovations and Trends in Tapered Roller Bearings Manufacturing

The manufacturing landscape for tapered roller bearings is witnessing significant innovations, particularly with the advent of advanced materials and processing techniques. According to a recent industry report, the global tapered roller bearings market is projected to grow at a compound annual growth rate (CAGR) of 4.5% from 2023 to 2030. This surge can be attributed to the increasing demand for these precision components in various industries, including automotive and aerospace, where the need for higher load capacities and improved performance characteristics is paramount.

One notable trend in the industry is the development of hybrid bearings, which combine steel and polymer materials. These innovations not only enhance the weight-to-strength ratio but also improve resistance to wear and corrosion. Additionally, the integration of smart technologies into manufacturing processes is transforming the way tapered roller bearings are designed and produced. Real-time monitoring systems and data analytics are enabling manufacturers to optimize production efficiency and minimize downtime, thereby significantly reducing operational costs. The increased emphasis on sustainability is also driving manufacturers to focus on eco-friendly practices, from sourcing raw materials to energy-efficient production methods.

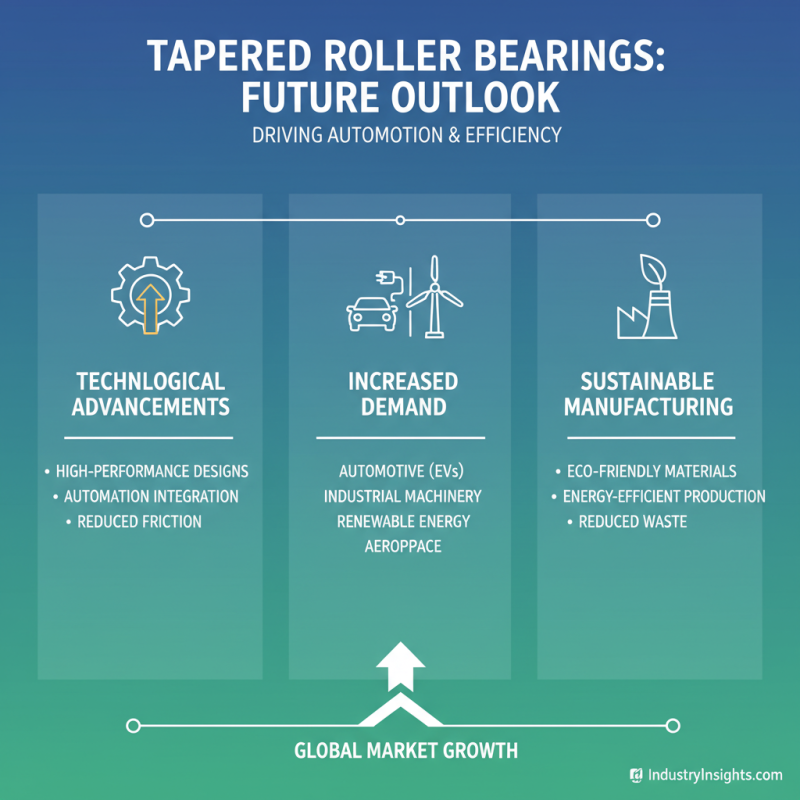

Future Outlook for Tapered Roller Bearings Supply Industry

The future outlook for the tapered roller bearings supply industry appears promising, driven by advancements in technology, increased demand from automotive and industrial sectors, and a shift towards sustainable manufacturing practices. As industries move towards automation and efficiency, the need for high-performance bearings is set to rise. The expansion of electric vehicles and renewable energy applications will further boost the demand for tapered roller bearings, which are crucial for improving energy efficiency and minimizing mechanical failures.

Moreover, the ongoing trend of globalization will play a significant role in shaping the supply chain of tapered roller bearings. Suppliers are increasingly focusing on developing strategic partnerships and alliances to enhance their production capabilities and reach new markets. Additionally, the integration of smart manufacturing technologies is expected to streamline operations, reduce costs, and enhance product quality. As companies invest in research and development, innovative solutions such as advanced materials and coatings will likely emerge, reinforcing the resilience and adaptability of the tapered roller bearings supply industry in the years to come.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us