Top 5 Tips for Thrust Ball Bearings Custom Manufacturing

Thrust Ball Bearings Custom Manufacturing plays a crucial role in various industries. These bearings are designed to handle axial loads efficiently. Many factors influence the custom manufacturing process. Choosing the right materials is essential, yet often overlooked. Each material impacts performance and durability.

Precision in design can make or break a project. Engineers must consider size and load ratings meticulously. Mistakes in these areas can lead to costly failures. Customizing involves adapting to specific applications, which can be challenging. Every decision counts, especially when balancing cost and quality.

Collaboration with manufacturers is vital. Clear communication prevents misalignment and errors. Asking the right questions can save time and resources. Embrace the complexity of Thrust Ball Bearings Custom Manufacturing for better outcomes. Challenges may arise, but with careful planning, success is achievable.

Understanding Thrust Ball Bearings and Their Applications

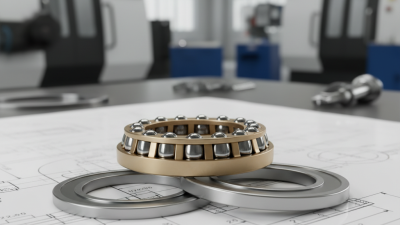

Thrust ball bearings play a vital role in various industries. They are designed to support axial loads while allowing for limited rotational movement. This unique feature makes them suitable for applications ranging from automotive to aerospace. According to a recent market report, the global thrust ball bearings market is expected to grow at a CAGR of 4.2% from 2021 to 2028, driven by increasing machinery and infrastructure demands.

In the automotive sector, thrust ball bearings are crucial for components like gearboxes and clutches. Their ability to withstand high radial loads ensures durability and performance. However, many manufacturers still overlook the importance of precision in custom manufacturing. Inconsistent tolerances can lead to premature failure and increased maintenance costs. This highlights the need for focusing on quality control in the production process.

In aerospace applications, thrust ball bearings must meet rigorous standards. They operate in extreme conditions and must be highly reliable. A failure can have catastrophic consequences. Some manufacturers struggle with sourcing materials that meet strict certifications. This creates a gap where improvement is essential. Addressing these challenges can lead to better performance and reduced risk in critical applications.

Key Factors in Custom Manufacturing of Thrust Ball Bearings

When considering custom manufacturing of thrust ball bearings, precision is vital. The alignment and surface finish must meet strict specifications. Small deviations can lead to significant performance issues. Ensuring the right materials is equally important. Common choices include stainless steel and bronze. Each has unique properties that affect durability and performance.

Next, machining techniques play a crucial role. Advanced methods improve consistency but require skilled operators. It's essential to monitor each step of the process. Mistakes in machining could lead to failures down the line. Additionally, incorporating quality control measures helps identify problems early. Testing under load conditions offers valuable insights.

Collaboration between engineers and production teams enhances the outcome. Open communication leads to better understanding of requirements. However, there can be challenges in balancing cost and quality. Sometimes, compromises result in suboptimal products. Continuous feedback and iterative improvements are necessary for success. The journey of manufacturing thrust ball bearings is complex, but attention to detail can lead to superior results.

Top 5 Tips for Thrust Ball Bearings Custom Manufacturing - Key Factors in Custom Manufacturing of Thrust Ball Bearings

| Tip |

Description |

Key Factor |

Importance |

| Understand Load Requirements |

Assess the axial loads the bearings will be subjected to. |

Load Analysis |

Critical for performance and lifespan. |

| Material Selection |

Choose materials that can withstand anticipated operating conditions. |

Durability |

Affects strength and corrosion resistance. |

| Precision Engineering |

Utilize CNC technology for accurate ball bearing components. |

Manufacturing Accuracy |

Essential for smooth operation. |

| Quality Control |

Implement strict testing measures for finished products. |

Assurance of Performance |

Reduces failure risk in applications. |

| Customization Options |

Offer tailored solutions to meet specific customer needs. |

Flexibility |

Enhances customer satisfaction and market competitiveness. |

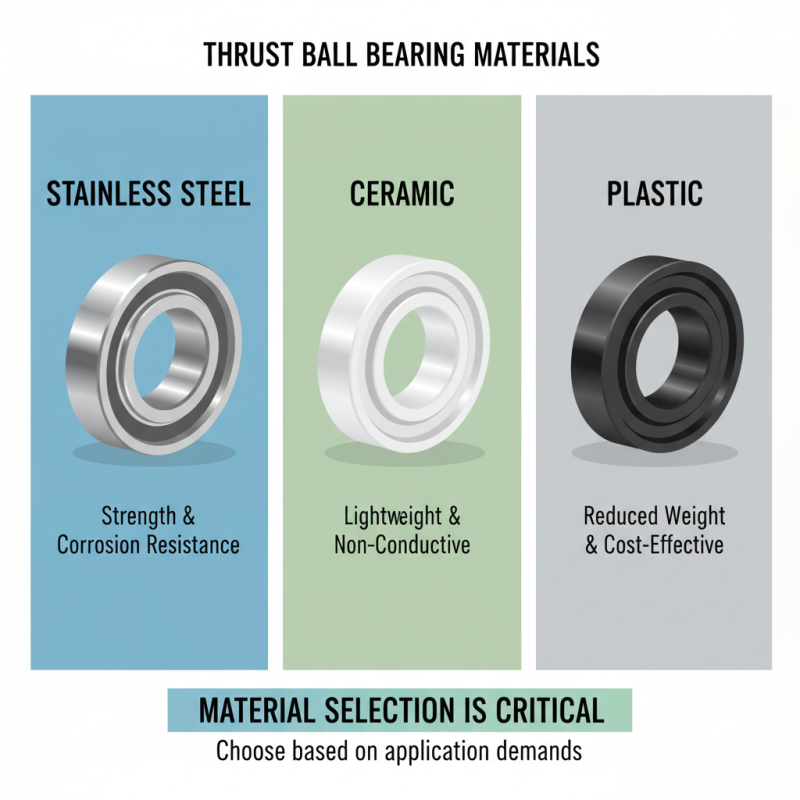

Materials and Design Considerations for Thrust Ball Bearings

When designing thrust ball bearings, material selection is critical. Common choices include stainless steel, which offers great strength and corrosion resistance. However, this might not be the best option for all applications. Some environments demand non-metallic materials. For example, plastic or ceramic can provide suitable alternatives. These materials can reduce weight and improve performance in certain applications.

Design considerations are equally important. The geometry of the bearing affects its load capacity and performance. Thrust ball bearings must be built to accommodate axial loads efficiently. An improper design can lead to premature failure. Take lubrication into account as well. The right lubricant reduces friction and wear. This affects the lifespan of the bearing significantly.

One area often overlooked is tolerance levels. Manufacturing tolerances must be precise to ensure smooth operation. Loose tolerances can create excessive play and lead to reduced performance. On the flip side, excessively tight tolerances can increase manufacturing costs. Finding a balance is essential. Overall, both material and design choices require careful thought. It’s a complex process, and reflection is key to success.

Quality Control Measures for Thrust Ball Bearing Production

Quality control is paramount in thrust ball bearing production. Statistical Process Control (SPC) techniques help monitor critical parameters. According to industry reports, implementing SPC can reduce defects by up to 40%. This significant drop in flaws not only enhances product reliability but also minimizes waste in manufacturing.

One key aspect of quality control involves rigorous testing of materials. Bearings produced with subpar materials often lead to premature failures. Regular inspections using advanced techniques, such as ultrasonic testing and surface analysis, ensure that only the best materials are used. Failure to employ these measures can result in costly recalls and reputation damage.

Additionally, employee training plays a crucial role. Skilled workers can identify subtle defects during manufacturing. A recent survey revealed that companies investing in workforce development experience 25% fewer quality issues. This correlation shows that employee expertise is vital for maintaining high standards. Neglecting this area could leave an organization vulnerable to problems that ripple through the supply chain.

Best Practices for Selecting a Manufacturer for Thrust Ball Bearings

Selecting the right manufacturer for thrust ball bearings is crucial. Reliable data from the Bearing Manufacturers Association indicates that poor supplier choices can increase production costs by up to 15%. A deep understanding of the manufacturing process helps. Opt for a manufacturer with expertise in thrust ball bearings. Their knowledge can influence your product's durability.

Consider evaluating a manufacturer’s ability to meet your specifications. Request samples to assess quality. Check their production capabilities and technology use. According to recent industry reports, firms using advanced automation in manufacturing achieve a efficiency rate of 30% higher compared to traditional methods. This can impact delivery times and overall costs.

Communication is often overlooked. Ensure the manufacturer understands your requirements fully. Good communication helps in addressing issues quickly. In a survey, 40% of businesses noted miscommunication in specifications led to product failures. Building a strong relationship with your manufacturer is essential. A partner who listens can help refine designs and improve outcomes. Aim for a collaborative process that fosters innovation.

Thrust Ball Bearings Custom Manufacturing: Key Factors for Selecting a Manufacturer

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us