Ultimate Guide to Angular Contact Bearings Industrial Grade Tips for Optimal Performance

In the realm of precision engineering, Angular Contact Bearings Industrial Grade stand out as vital components that enhance the performance and reliability of various machinery. These bearings are specifically designed to accommodate both axial and radial loads, making them essential for applications where high-speed operations and precise rotational accuracy are crucial. This ultimate guide seeks to delve into the intricacies of angular contact bearings, offering insights into their construction, functionality, and optimal usage.

Understanding the characteristics of Angular Contact Bearings Industrial Grade is key to maximizing the efficiency of any industrial application. From their unique angle design that allows for improved load distribution to their critical role in maintaining the stability of rotating parts, these bearings are indispensable in various sectors such as manufacturing, automotive, and aerospace. By exploring the best practices for selection, installation, and maintenance of these bearings, readers will be equipped with the knowledge necessary to ensure optimal performance and longevity in their applications.

In this comprehensive guide, we will cover essential tips and common pitfalls to avoid, ensuring that those who rely on Angular Contact Bearings Industrial Grade can achieve unmatched operational precision and minimize downtime. Whether you are an engineer, technician, or enthusiast, this resource will serve as a go-to reference for harnessing the full potential of these pivotal components in your machinery.

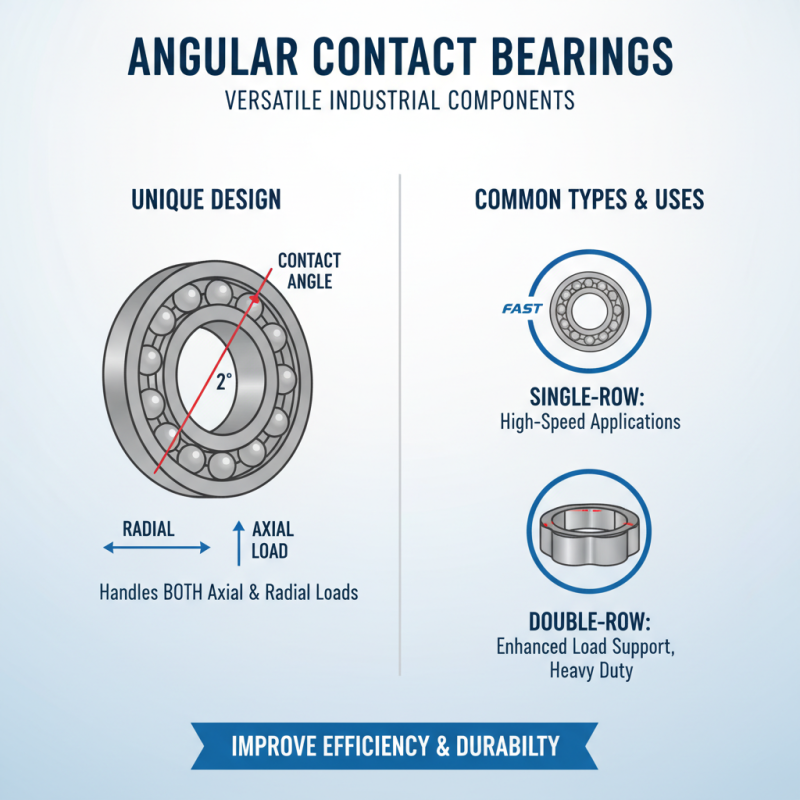

Understanding Angular Contact Bearings: Definition and Functionality

Angular contact bearings are a crucial component in many industrial applications, primarily due to their ability to support both radial and axial loads simultaneously. These bearings are characterized by the angle of contact between the rolling elements and the raceway, which typically ranges from 15 to 40 degrees. This angle allows for higher load capacities and improved performance in high-speed operations. According to the International Journal of Engineering Research and Applications, angular contact bearings are essential in machinery where precision and reliability are paramount, such as in robotics, aerospace, and various automation industries.

When selecting angular contact bearings, one key consideration is the arrangement of the bearings in relation to the shaft. For optimal performance, it is recommended to use paired angular contact bearings to handle axial loads effectively. Similarly, the preload setting of the bearings significantly influences their operational efficiency. A report from the American Bearing Manufacturers Association indicates that properly preloaded bearings can reduce vibration, prolong service life, and enhance accuracy in applications.

Tips for Optimal Performance: Ensure proper lubrication by selecting the right lubricant type and viscosity according to the operating environment. Additionally, regular maintenance and monitoring for wear signs can prevent unexpected failures and extend the lifespan of your bearings. Understanding the importance of these factors can lead to enhanced reliability and decreased downtime in your operations.

Different Types of Angular Contact Bearings and Their Applications

Angular contact bearings are a crucial component in various industrial applications due to their unique design, which allows them to handle both axial and radial loads simultaneously. These bearings are typically characterized by their contact angle, which significantly influences their load carrying capacity and operational efficiency. Common types include single row angular contact bearings, which are designed for high-speed applications, and double row angular contact bearings, which provide enhanced load support for heavier or more demanding operations.

The applications of angular contact bearings span a wide range of industries. In the automotive sector, they are often utilized in wheel hubs and transmissions, where precise load handling and minimal friction are essential for performance. In the aerospace industry, their reliability and ability to withstand high speeds make them ideal for turbine engines and landing gear. Additionally, these bearings are found in precision machinery, such as CNC equipment, where accurate positioning and stability are critical. The selection of the appropriate type of angular contact bearing based on the specific application requirements can significantly affect the overall performance and longevity of the equipment.

Key Factors Affecting the Performance of Angular Contact Bearings

Angular contact bearings are critical components in various industrial applications, characterized by their ability to handle both radial and axial loads. The performance of these bearings can be influenced by several key factors, including preload, material quality, alignment, and lubrication. According to a recent report by the American Bearing Manufacturers Association (ABMA), proper preload is essential for maximizing the load-carrying capacity and minimizing the risk of fatigue failure in angular contact bearings. Preloading ensures tighter contact between the rolling elements and raceways, which enhances stability during operation and reduces the likelihood of maintenance issues.

Another important factor affecting the performance of angular contact bearings is the quality of the bearing materials. Research indicates that high-grade steel, such as bearing steel conforming to ISO 683-17 standards, significantly improves the fatigue life and wear resistance of the bearings. Moreover, the manufacturing process, including heat treatment and surface finish, plays a pivotal role in determining the operational efficiency of these bearings. A survey published by the Journal of Mechanical Engineering showed that precision alignment during installation can also enhance bearing life by up to 30%, emphasizing the need for careful handling and setup to achieve optimal performance in machinery.

Lastly, effective lubrication is paramount for reducing friction and preventing overheating in angular contact bearings. According to the National Lubricating Grease Institute (NLGI), proper lubrication interval and selection based on viscosity can decrease wear by as much as 50%. Additionally, the introduction of advanced lubrication technology, such as solid lubricants and synthetic oils, is revolutionizing the maintenance practices, driving performance improvements, and extending the operational lifespan of bearings across industrial environments.

Ultimate Guide to Angular Contact Bearings Industrial Grade Tips for Optimal Performance

| Bearing Type |

Load Capacity (N) |

Max Speed (RPM) |

Material |

Lubrication Type |

Operating Temperature Range (°C) |

| Single Row Angular Contact Bearing |

5100 |

15000 |

Steel |

Grease |

-30 to 120 |

| Double Row Angular Contact Bearing |

8800 |

12000 |

Ceramic |

Oil |

-40 to 150 |

| Four Point Angular Contact Bearing |

6000 |

10000 |

Stainless Steel |

Grease |

-20 to 120 |

| Angular Contact Thrust Bearing |

7500 |

6000 |

Bronze |

Oil |

-10 to 130 |

Maintenance Tips for Maximizing Angular Contact Bearings Lifespan

Maintaining angular contact bearings is crucial for ensuring their longevity and optimal performance in various industrial applications. According to a 2021 report from the International Journal of Precision Engineering and Manufacturing, regular maintenance can increase the lifespan of these bearings by up to 50%. One effective maintenance strategy involves monitoring the operating conditions to prevent overheating, as elevated temperatures can lead to premature wear. Keeping the operating temperature below 70°C is often recommended to minimize thermal degradation and extend service life.

Additionally, the lubrication regime significantly affects the performance and durability of angular contact bearings. The American Bearing Manufacturers Association suggests using high-quality lubricants suited for specific operational conditions, typically changing them at intervals of 1,000 hours of run time or based on contamination levels. Implementing a routine inspection schedule to check for signs of wear, such as surface pitting or abnormal noise, can also help in identifying issues before they escalate, ensuring that the bearings remain in optimal working condition.

By adhering to these maintenance tips, industries can not only enhance the functional lifespan of their angular contact bearings but also improve overall machinery reliability.

Common Issues and Troubleshooting for Angular Contact Bearings

When dealing with angular contact bearings, knowing common issues can help ensure optimal performance in industrial applications. One frequent problem is misalignment, which can lead to excessive wear and noise. Misalignment often occurs due to improper installation or a lack of maintenance. Regularly checking the alignment during routine machinery assessments can help identify this issue early, preventing further complications.

Another common issue is inadequate lubrication, which can result in increased friction and bearing failure. It’s essential to use the correct lubricant and maintain appropriate levels. Over-lubrication can also cause problems, leading to overheating and reduced performance. To avoid these pitfalls, develop a consistent lubrication schedule and monitor operating temperatures.

**Tips:** To enhance the lifespan of your angular contact bearings, ensure they are installed correctly by following manufacturer guidelines. Additionally, consider implementing vibration analysis as a preventive measure; this technique can detect early signs of wear and help in timely troubleshooting. Lastly, maintain a clean operating environment to minimize contamination and extend bearing life.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us