Exploring Unique Applications of Thrust Ball Bearings in Custom Manufacturing Solutions

In the realm of precision engineering and manufacturing, the significance of Thrust Ball Bearings Custom Manufacturing has surged to the forefront of various industries. According to a report by Market Research Future, the global bearing market is projected to grow at a CAGR of 5.3% from 2020 to 2027, driven by the increasing demand for high-performance components. Thrust ball bearings, known for their ability to handle axial loads with efficiency and reliability, are increasingly being tailored to meet specific operational requirements in custom manufacturing solutions.

With applications spanning sectors such as aerospace, automotive, and robotics, the customization of these bearings can lead to enhanced performance, reduced maintenance costs, and extended service life. This article delves into the unique applications of thrust ball bearings, exploring how custom designs can transform manufacturing processes and deliver strategic advantages in today’s competitive landscape.

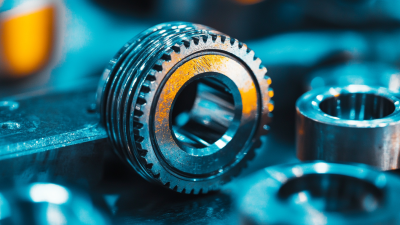

Unique Features of Thrust Ball Bearings in Customized Manufacturing

Thrust ball bearings are essential components in various custom manufacturing solutions due to their unique design and operational features. These bearings are specifically engineered to support axial loads while allowing for limited radial loads, making them ideal for applications requiring precise positioning and stability. Their ability to handle high-speed operations, particularly in vertical or slanted arrangements, contributes significantly to the reliability and efficiency of machinery in specialized sectors such as aerospace and automotive manufacturing.

One of the standout features of thrust ball bearings is their customizable size and configuration, allowing manufacturers to tailor these components to meet specific operational requirements. This flexibility enables the incorporation of thrust ball bearings in a range of bespoke applications, from robotic systems to fluid dynamics setups. Additionally, the materials used in their construction can vary, providing options for enhanced corrosion resistance and durability. As industries strive for greater efficiency and performance in customized solutions, the integrated use of thrust ball bearings proves to be a crucial factor in maximizing productivity and minimizing downtime.

Innovative Applications of Thrust Ball Bearings Across Industries

Thrust ball bearings are often overlooked in the realm of custom manufacturing, yet their unique applications across various industries highlight their versatility and importance. These specialized bearings excel in handling axial loads, making them ideal for use in automotive systems, aerospace components, and heavy machinery. For instance, in the automotive sector, thrust ball bearings support the thrust loads in gearboxes and differential assemblies, ensuring smooth operation and prolonging the lifespan of critical components.

When considering the integration of thrust ball bearings into your design, it's crucial to evaluate their load capacities and alignment requirements. A well-aligned bearing will minimize friction and wear, increasing efficiency. Here are a few tips: always choose a bearing that matches the specific load requirements of your application, and consider the material of the bearing to ensure it can withstand the operational environment, whether it's high temperatures or exposure to corrosive elements.

In the aerospace field, thrust ball bearings can be found in applications ranging from turbine engines to landing gear mechanisms. Their ability to support significant axial loads while allowing for high-speed rotation makes them invaluable. For manufacturers looking to innovate, understanding the various types of thrust bearings available and their specifications can lead to unexpected solutions that enhance product performance and reliability.

Exploring Unique Applications of Thrust Ball Bearings in Custom Manufacturing Solutions

| Application Industry |

Specific Use Case |

Benefits of Using Thrust Ball Bearings |

Challenges Addressed |

| Aerospace |

Rotor assemblies |

High load capacity and precision |

Vibration and temperature control |

| Automotive |

Steering mechanisms |

Improved steering precision |

Wear and tear from high friction |

| Industrial Machinery |

CNC machines |

Enhanced load support and accuracy |

Heavy operational stresses |

| Renewable Energy |

Wind turbine generators |

Durability under environmental extremes |

High torque and fluctuating forces |

| Medical Devices |

Surgical tools |

Smooth operation and reliability |

Precision under high usage |

How Thrust Ball Bearings Enhance Precision in Custom Solutions

Thrust ball bearings play a pivotal role in enhancing precision in custom manufacturing solutions, making them indispensable in various industrial applications. These bearings are specifically designed to accommodate axial loads, effectively reducing friction and wear in high-precision mechanisms. This unique capability allows manufacturers to achieve tighter tolerances and more efficient operations, resulting in improved overall performance of machinery and equipment.

As the global bearings market continues to expand, projected to grow significantly over the next decade, the demand for high-quality thrust ball bearings is also on the rise. With their ability to support heavy loads while maintaining smooth movement, they are increasingly favored in sectors such as aerospace, automotive, and robotics. The integration of thrust ball bearings into custom solutions not only addresses specific manufacturing challenges but also enhances the reliability and longevity of the equipment, ultimately driving innovation across various industries.

Key Benefits of Utilizing Thrust Ball Bearings in Specialized Manufacturing

Thrust ball bearings are gaining prominence in specialized manufacturing due to their numerous advantages, particularly in applications where axial load management is crucial. These bearings offer minimal friction, which enhances the efficiency and longevity of machinery in sectors such as aerospace, automotive, and precision engineering. Their ability to support high axial loads while maintaining rotational movement allows manufacturers to design robust solutions tailored to specific operational needs.

The global bearings market is projected to witness significant growth, escalating from USD 50.16 billion in 2025 to an estimated USD 97.10 billion by 2030. This growth trajectory underscores the increasing demand for advanced components, including thrust ball bearings, as manufacturers seek to optimize performance and reduce downtime. By integrating thrust ball bearings into custom manufacturing solutions, companies can not only improve machine reliability but also enhance overall productivity, making them an essential choice for businesses aiming to remain competitive in a dynamic market.

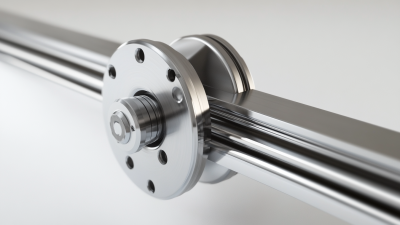

Design Considerations for Implementing Thrust Ball Bearings Effectively

When integrating thrust ball bearings into custom manufacturing solutions, design considerations play a crucial role in maximizing performance and reliability. Firstly, understanding the load requirements is essential. Thrust ball bearings are specifically designed to handle axial loads, and their selection must reflect the nature of the applied loads in a given application. For instance, in high-speed machinery where significant axial forces are present, selecting a bearing with a higher load rating and suitable materials can prevent premature wear and failure.

Another vital consideration is the alignment and mounting of the bearings. Proper alignment not only ensures optimal performance but also enhances durability. Misalignment can lead to uneven wear and excessive heat generation, compromising the integrity of the bearing. Additionally, incorporating features such as lubrication systems can significantly improve the lifespan of thrust ball bearings. Ensuring adequate lubrication reduces friction and heat buildup, thus maintaining efficient operation even under heavy loads. By addressing these design aspects, manufacturers can harness the full potential of thrust ball bearings, leading to innovative and effective custom solutions.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us