Solutions for Urgent Bearing Supply Needs: Your Trusted Global Partner

In the fast-paced industrial landscape, companies often face unexpected machinery breakdowns that demand immediate attention and solutions, highlighting the critical role of an Emergency Bearing Order Supplier. According to a recent report by the International Bearing Association, the global bearing market is projected to reach over $100 billion by 2025, driven in part by the increasing need for operational efficiency and rapid response strategies. Bearing failures can lead to costly downtimes, with research indicating that unplanned downtime can cost manufacturers as much as $260,000 per hour. Therefore, having a reliable partner who can provide urgent bearing supply solutions is essential for maintaining productivity and competitiveness.

This guide aims to explore the strategies and best practices for selecting the right supplier to ensure that your operations remain seamless, even in emergencies.

Understanding the Importance of Timely Bearing Supply in Industry

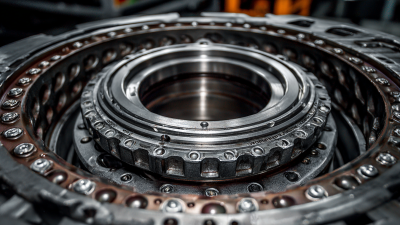

Timely bearing supply is crucial in various industries, as delays can lead to halted production lines and significant financial losses. Bearings play a pivotal role in machinery and equipment, ensuring smooth operation and minimizing friction. When a machinery component fails due to a bearing issue, the impact can ripple through the entire operation, causing downtime and burnout among staff. Therefore, having a reliable partner for urgent bearing needs can be the difference between maintaining operational efficiency and facing costly interruptions.

In today’s fast-paced industrial landscape, the ability to receive bearings quickly can enhance a company’s responsiveness to market demands. Suppliers who understand the intricacies of bearing logistics can streamline the process, ensuring that critical components are readily available when needed. This responsiveness not only strengthens relationships with customers but also positions businesses to seize new opportunities without the constraints of waiting for essential supplies. Ultimately, prioritizing timely bearing supply is not just a logistical concern; it is a strategic imperative that can drive competitive advantage in the marketplace.

Solutions for Urgent Bearing Supply Needs: Your Trusted Global Partner

| Bearing Type |

Lead Time (Days) |

Application Area |

Stock Availability |

Supplier Rating (out of 5) |

| Deep Groove Ball Bearing |

7 |

Automotive, Machinery |

In Stock |

4.5 |

| Angular Contact Ball Bearing |

10 |

High-speed Applications |

Limited Stock |

4.0 |

| Spherical Roller Bearing |

14 |

Heavy Equipment |

In Stock |

4.8 |

| Needle Roller Bearing |

5 |

Automotive, Aerospace |

In Stock |

4.6 |

| Thrust Bearing |

12 |

Industrial Machinery |

Limited Stock |

4.2 |

Innovative Solutions for Meeting Urgent Bearing Demands

In today's fast-paced industrial landscape, meeting urgent bearing demands is crucial for maintaining operational efficiency and minimizing downtime. Innovative solutions are now more important than ever, as companies face the pressures of quick turnarounds and the need for reliable components. Our commitment to providing high-quality bearings paired with swift delivery services sets us apart as a trusted global partner. By leveraging advanced logistics and supply chain management techniques, we ensure that our clients receive the bearings they need precisely when they need them.

To further address urgent requirements, we have invested in cutting-edge technologies that enhance our manufacturing processes. This includes real-time inventory tracking and automated production systems, which enable us to respond rapidly to fluctuating market demands. Our dedicated engineering teams collaborate with clients to develop customized solutions, ensuring that even the most specific bearing needs are met without delay. By prioritizing innovation and responsiveness, we empower businesses to maintain productivity and drive growth in their operations.

Solutions for Urgent Bearing Supply Needs

This bar chart illustrates the supply volume for various types of bearings to meet urgent demands. As depicted, standard bearings have the highest supply volume, followed by emergency stocks, while custom bearings have the lowest supply volume.

Benefits of Partnering with a Global Bearing Supplier

In today's fast-paced industrial landscape, the demand for high-quality bearings is on the rise, with the global bearing market projected to reach approximately $80 billion by 2026, growing at a CAGR of 5.2% (Mordor Intelligence). Partnering with a global bearing supplier offers significant advantages, particularly when tackling urgent supply needs. These suppliers not only provide access to a diverse range of products but also ensure that companies can meet production timelines, especially during peak demand periods.

A key benefit of partnering with a reliable global supplier lies in the enhanced supply chain efficiency. With established logistics networks, these partners can reduce lead times and improve inventory management. According to a report by Research and Markets, companies that collaborate with global suppliers can achieve a cost reduction of up to 20% by optimizing procurement and minimizing delays. Furthermore, global suppliers often bring technical expertise and innovation, enabling businesses to adopt advanced bearing technologies that improve performance and reliability, crucial for sectors like automotive and manufacturing where operational downtime can result in substantial losses.

Future Trends in Bearing Technology and Supply Chain Management

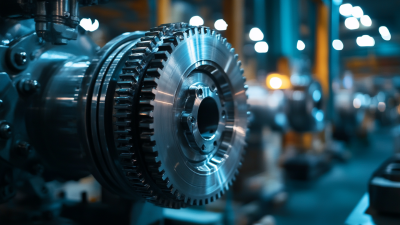

The future of bearing technology is poised for significant advancements, driven by the increasing demand for efficiency and precision in various industries. Innovations such as smart bearings, which integrate sensors and IoT capabilities, are becoming crucial for real-time monitoring and predictive maintenance. These developments not only enhance the performance of machinery but also significantly reduce downtime, allowing businesses to operate more efficiently. As manufacturers leverage data analytics, the predictive aspects of these smart bearings foster a proactive approach to maintenance and supply chain management.

In parallel, supply chain management for bearings is evolving in response to global challenges. The reliance on just-in-time inventory systems is being reassessed due to disruptions experienced in recent years. Companies are now focusing on creating more resilient supply chains, embracing diversified sourcing strategies and localized manufacturing to mitigate risks. Adopting advanced technologies such as blockchain for transparency and traceability in the supply chain can enhance trust and reliability. As these trends unfold, businesses can not only address urgent supply needs but also position themselves strategically for future growth in an increasingly competitive landscape.

Strategies to Enhance Responsiveness in Bearing Supply Networks

In today's fast-paced manufacturing environment, enhancing the responsiveness of bearing supply networks is critical for success. As companies face increasing pressure to deliver products quickly and efficiently, strategies to bolster supply chain performance have become paramount. Research shows that firms that cultivate high-quality multi-directional relationships can significantly dilute supply risks. For example, companies that prioritize collaborative communication with suppliers and customers are 30% more likely to mitigate disruptions effectively, according to recent empirical studies.

To improve your supply network's responsiveness, consider implementing advanced modeling strategies, such as integrating renewable energy systems. These systems have proven effective in balancing fluctuating supply and demand, especially in regions with variable energy resources. By incorporating flywheel and hydrogen-based solutions, businesses can enhance their operational resilience and sustainability.

Tip: Regularly assess and strengthen your supplier partnerships. Establishing trust and open lines of communication can lead to more agile reactions to supply chain fluctuations. Additionally, utilizing technology for real-time data analysis can help identify potential disruptions before they escalate, ensuring that your supply network remains robust and responsive.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us